Your Bleaching of cotton fabric pdf images are available in this site. Bleaching of cotton fabric pdf are a topic that is being searched for and liked by netizens now. You can Download the Bleaching of cotton fabric pdf files here. Get all free vectors.

If you’re searching for bleaching of cotton fabric pdf pictures information linked to the bleaching of cotton fabric pdf interest, you have come to the ideal site. Our site always gives you suggestions for viewing the highest quality video and picture content, please kindly surf and locate more enlightening video articles and images that fit your interests.

Bleaching Of Cotton Fabric Pdf. 12 gL sodium perborate. Each process will be covered in this document. The obtained results reveal that bleached cotton fabric with satisfactory whiteness index and reasonable tensile strength can be obtained by treating the fabric at 95 C in a bleaching bath containing 5 gl sodium chlorite 002 gl hexamethylenetetramine and 1 gl non-ionic wetting agent using a material to liquor ratio of 130. Grey cotton fabric contains natural color and impurities on its surface.

Pdf Effect Of Different Types Scouring Against Different Types Of Bleaching Process On Dyeing Of Cotton Fabric With Monochlorotriazine Hot Brand Reactive Dye From researchgate.net

Pdf Effect Of Different Types Scouring Against Different Types Of Bleaching Process On Dyeing Of Cotton Fabric With Monochlorotriazine Hot Brand Reactive Dye From researchgate.net

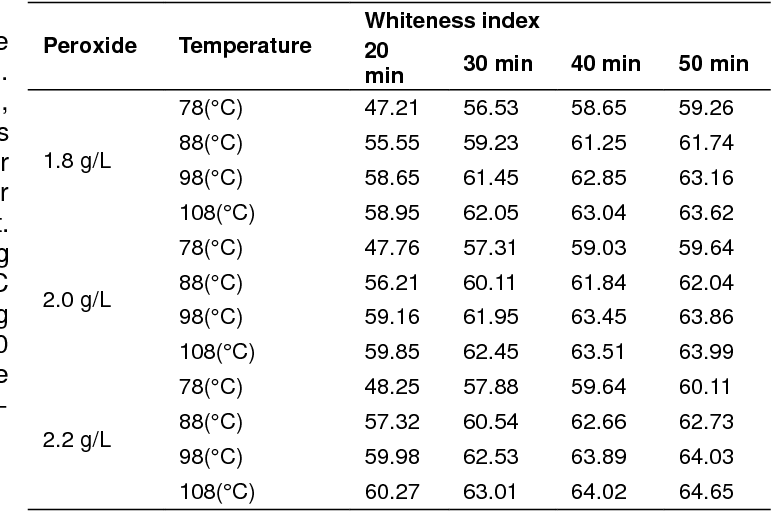

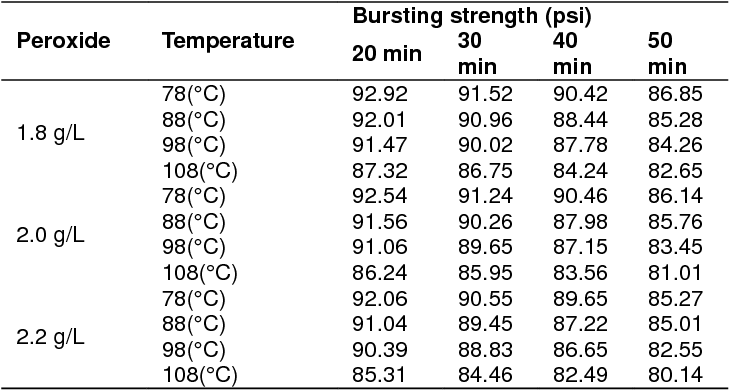

Up to 10 cash back Cotton fabric was bleached at a pilot-plant scale with the activated peroxide system based on N-4-triethylammoniomethyl benzoyl caprolactam chloride TBCCThe performance of the TBCC-activated peroxide system on low-temperature bleaching of cotton fabric was evaluated by measuring the degree of whiteness degree of polymerization. 1 mixing a chlorine dioxide solution with a sulfamic acid solution according to a volume ratio of 501 and uniformly stirring. The purpose of this study was to explore the possibility of bleaching. The fabric also has a smoother and more lustrous look when mercerized under tension. Each process requires a plethora of chemicals along with water out of which the unexhausted chemicals are drained in the. Peroxide bleaching keeps the Fiber quality intact in terms of Tensile Strength.

Peroxide bleaching keeps the Fiber quality intact in terms of Tensile Strength.

The treatment was carried out at 60 C for 45 min. Nonwoven fabrics can be produced using raw unbleached cotton. The destruction of natural coloring matter from the textile. The obtained results reveal that bleached cotton fabric with satisfactory whiteness index and reasonable tensile strength can be obtained by treating the fabric at 95 C in a bleaching bath containing 5 gl sodium chlorite 002 gl hexamethylenetetramine and 1 gl non-ionic wetting agent using a material to liquor ratio of 130. The obtained results reveal that bleached cotton fabric with satisfactory whiteness index and reasonable tensile strength can be obtained by treating the fabric at 95 C in a bleaching bath containing 5 gl sodium chlorite 002 gl hexamethylenetetramine and 1 gl non-ionic wetting agent using a material to liquor ratio of 130. Material Well scoured cotton fabric 2 x 2 grams each Stock solution.

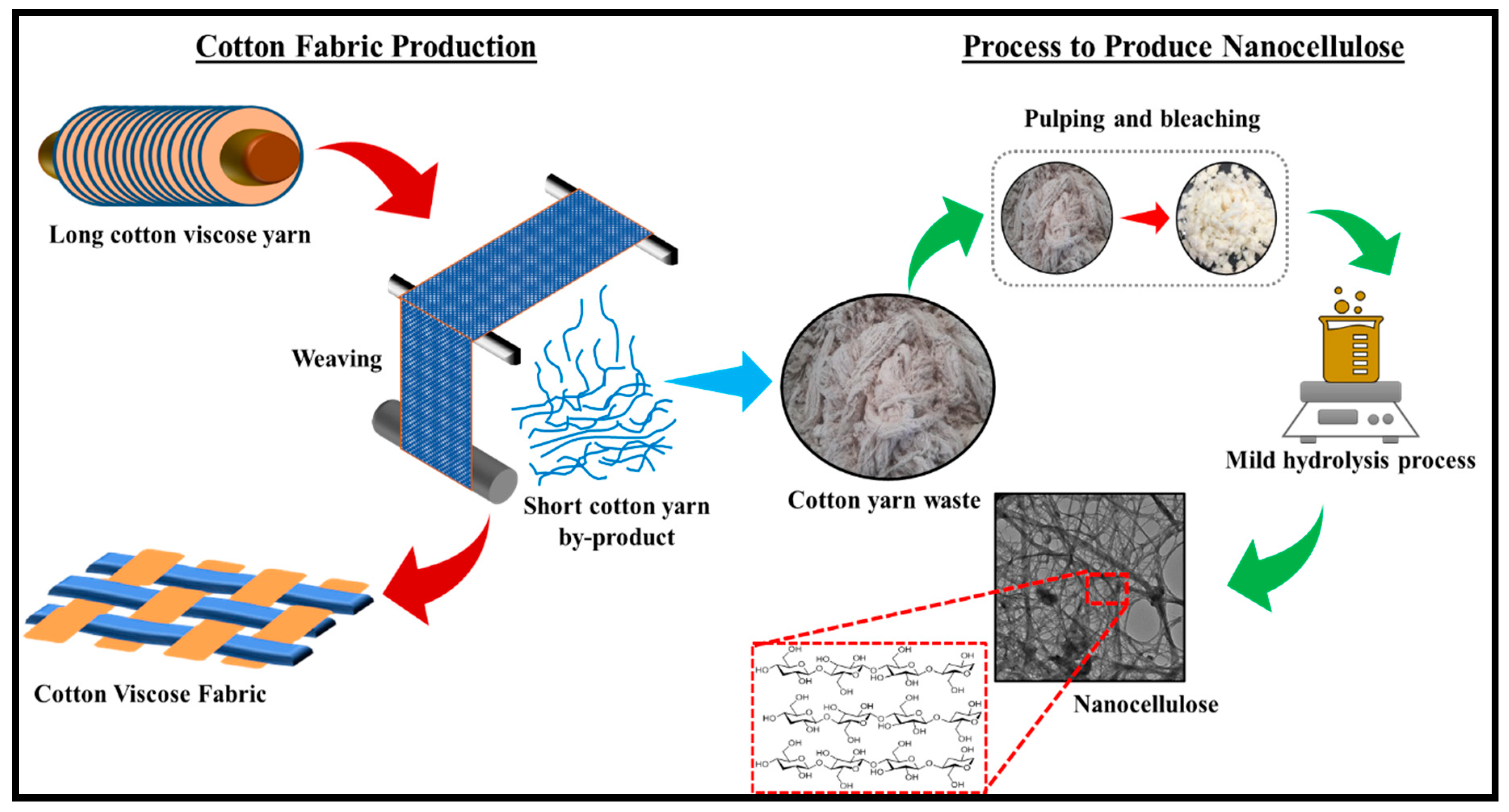

Source: mdpi.com

Source: mdpi.com

Bleaching is done for removing natural color which is inherent in the fiber. The treatment was carried out at 60 C for 45 min. From 5 - 5000 litkg of fabric processed. To remove those impurities and improve whiteness cotton is treated with bleaching agents. This bioprocess achieved high quality cottonPA fabric whiteness to the conventional system at much shorter batch times and with.

Source: semanticscholar.org

Source: semanticscholar.org

Scouring and bleaching of 100 cotton knitted fabric at combined stage. The optimum bleaching recipe consists of 20 gL tetraacetylethylenediamine. 20 million tons of Cotton is processed worldwide yearly. 6535 cottonpolyester blend fleece knitted fabric yarn count 34s fabric weight 180 GSM was taken in consideration for investigation. Scouring and bleaching of 100 cotton knitted fabric at combined stage.

Source: researchgate.net

Source: researchgate.net

Read article about Bleaching increase in whiteness of Cotton textile material. Aver age consumption in the scouring and bleaching of cotton fabrics was found to be in the range of 10 - 80 litkg and 10-130 litkg respectively depending on the machine and proc ess employed. Scouring and bleaching of 100 cotton knitted fabric at combined stage. The obtained results reveal that bleached cotton fabric with satisfactory whiteness index and reasonable tensile strength can be obtained by treating the fabric at 95 C in a bleaching bath containing 5 gl sodium chlorite 002 gl hexamethylenetetramine and 1 gl non-ionic wetting agent using a material to liquor ratio of 130. Reported the usability of ozone in the bleaching of cotton fabric.

Source: researchgate.net

Source: researchgate.net

Mercerization gives a much richer and more vibrant color saturation than with unmercerized versions of the same cotton fabric. Each process will be covered in this document. This bioprocess achieved high quality cottonPA fabric whiteness to the conventional system at much shorter batch times and with. Mercerization gives a much richer and more vibrant color saturation than with unmercerized versions of the same cotton fabric. And 1 gL nonionic wetting agent.

Source: academia.edu

Source: academia.edu

Scouring and bleaching of 100 cotton knitted fabric at combined stage. Up to 10 cash back The ozone bleaching of cotton fabrics has been studied before for example Prabaharan and Rao Perincek et al. The obtained results reveal that bleached cotton fabric with satisfactory whiteness index and reasonable tensile strength can be obtained by treating the fabric at 95 C in a bleaching bath containing 5 gl sodium chlorite 002 gl hexamethylenetetramine and 1 gl non-ionic wetting agent using a material to liquor ratio of 130. Inthis project I used three different oxidative bleaching agents such as- Hydrogen. The destruction of natural coloring matter from the textile.

Source: scielo.br

Source: scielo.br

Mercerization gives a much richer and more vibrant color saturation than with unmercerized versions of the same cotton fabric. Reported the usability of ozone in the bleaching of cotton fabric. Scouring and bleaching of 100 cotton knitted fabric at combined stage. Simple and sustainable reuse and recycle strategies were investigated with the intention of assessing ways to curb water consumption in the textile wet processing. Scouring is the process of removing the impurities such as oil fat wax dust and dirt from the textile material to make it hydrophilic.

Source: academia.edu

Source: academia.edu

Read article about Bleaching increase in whiteness of Cotton textile material. The aim of this lab is to bleach the already scoured cotton fabric to determine any differences in appearance between the unbleached and the bleached fabric. Hydrogen peroxide is highly used bleaching agent for bleaching of. After scouring process bleaching is done for get white fabric. This bioprocess achieved high quality cottonPA fabric whiteness to the conventional system at much shorter batch times and with.

Source: researchgate.net

Source: researchgate.net

The purpose of this study was to explore the possibility of bleaching. And Piccoli et al. Certain nonwoven fabrics have enough integrity to allow for bleaching after fabric formation which eliminates the need for using more costly bleached fiber. 12 gL sodium perborate. The invention discloses a method for bleaching a cotton fabric by chlorine dioxide.

Source: researchgate.net

Source: researchgate.net

After scouring process bleaching is done for get white fabric. Simple and sustainable reuse and recycle strategies were investigated with the intention of assessing ways to curb water consumption in the textile wet processing. The obtained results reveal that bleached cotton fabric with satisfactory whiteness index and reasonable tensile strength can be obtained by treating the fabric at 95 C in a bleaching bath containing 5 gl sodium chlorite 002 gl hexamethylenetetramine and 1 gl non-ionic wetting agent using a material to liquor ratio of 130. Each process requires a plethora of chemicals along with water out of which the unexhausted chemicals are drained in the. To remove those impurities and improve whiteness cotton is treated with bleaching agents.

Source: semanticscholar.org

Source: semanticscholar.org

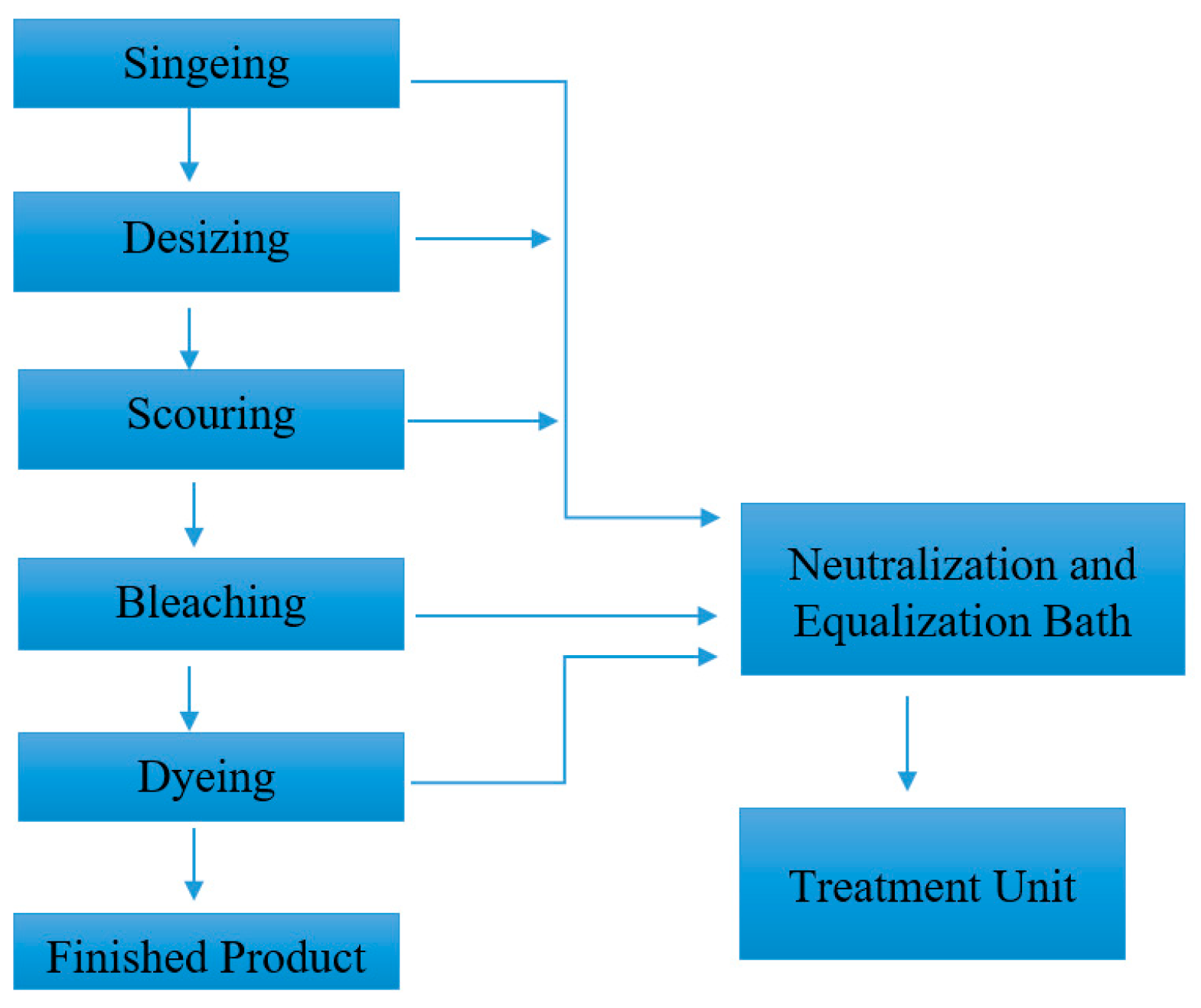

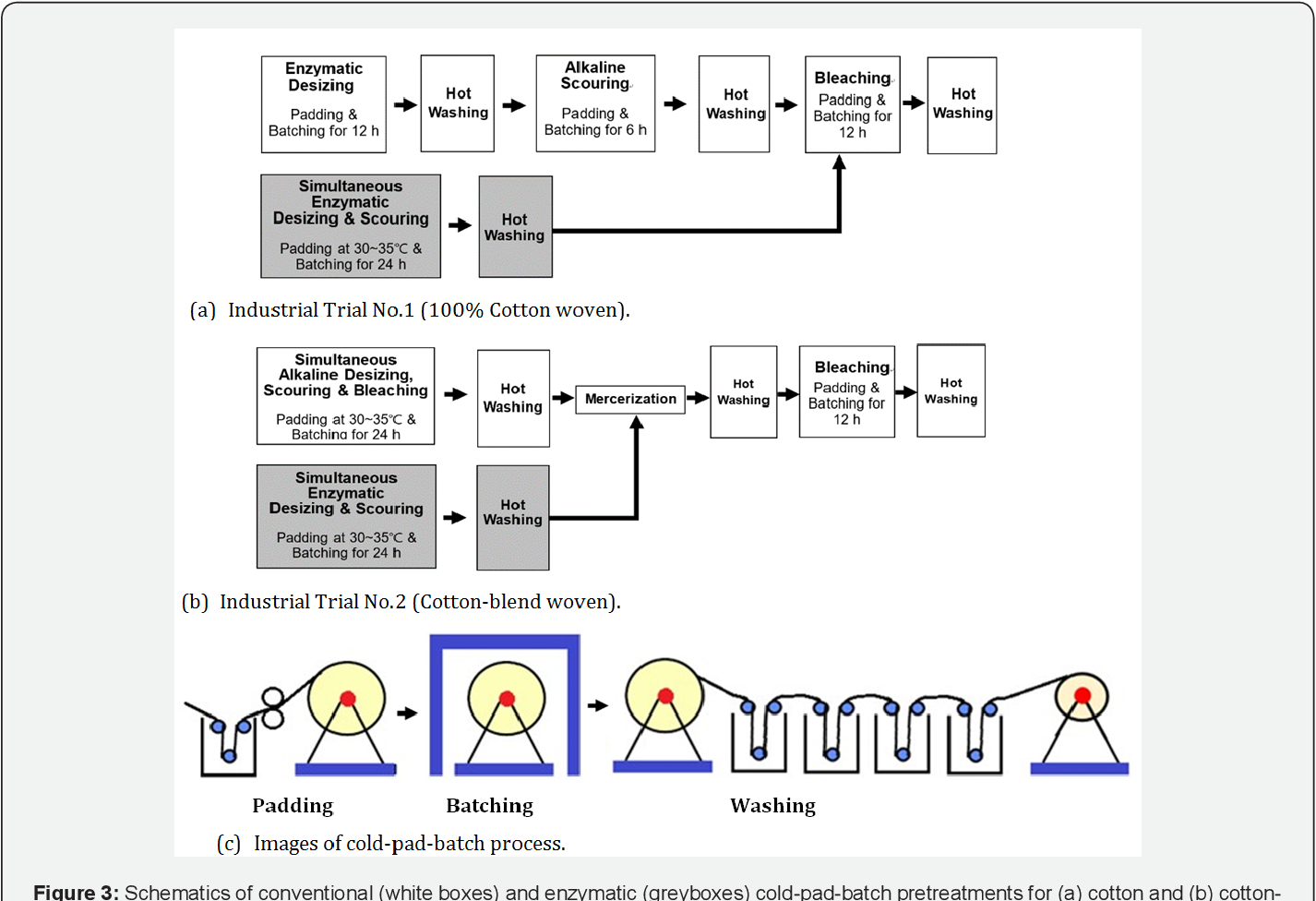

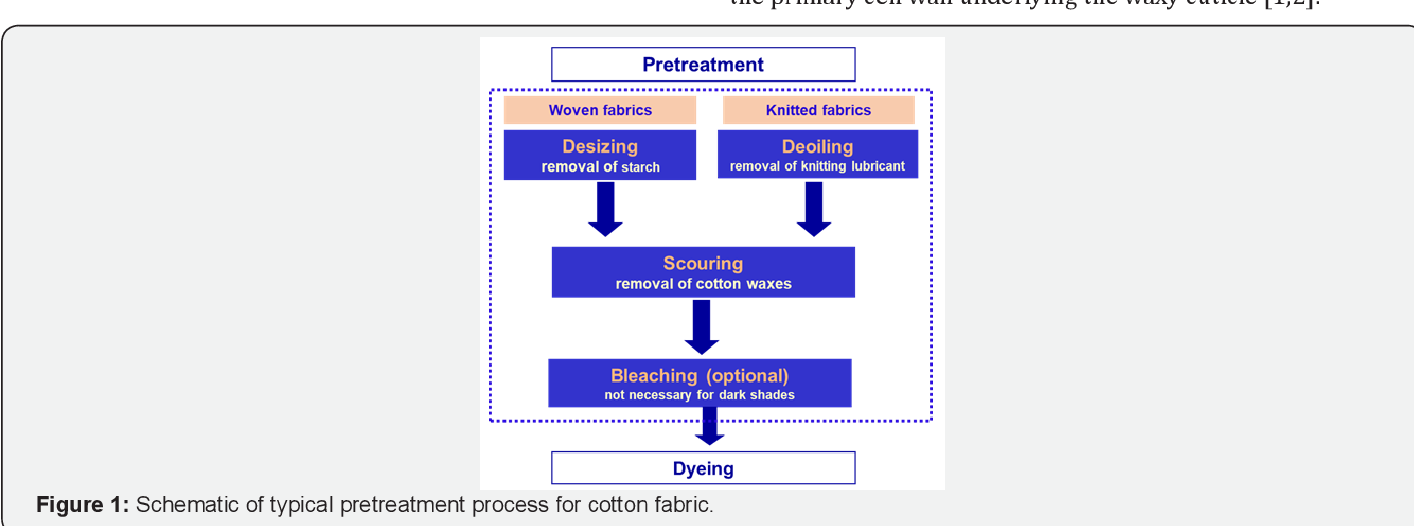

From 5 - 5000 litkg of fabric processed. The purpose of this study was to explore the possibility of bleaching. Cotton fabric by hydrogen peroxide with varying temperature and time and analyze the effects on weight loss and whiteness and to achieve an acceptable degree of whiteness CIE whiteness index 75 with minimum. Typical preparation processes used for cotton and cotton blend yarns and fabrics include singeing desizing scouring bleaching mercerizing cotton only heat setting synthetic fibers only and cellulose enzyme treatments. Bleaching is the second steps of pretreatment of textile materials as well as wet processing technology.

Source: mdpi.com

Source: mdpi.com

The fabric also has a smoother and more lustrous look when mercerized under tension. Bleaching is the second steps of pretreatment of textile materials as well as wet processing technology. Up to 10 cash back Cotton fabric was bleached at a pilot-plant scale with the activated peroxide system based on N-4-triethylammoniomethyl benzoyl caprolactam chloride TBCCThe performance of the TBCC-activated peroxide system on low-temperature bleaching of cotton fabric was evaluated by measuring the degree of whiteness degree of polymerization. To prepare the cotton fabric ready for Dyeing printing and finishing scouring bleaching is the fundamental step. Inthis project I used three different oxidative bleaching agents such as- Hydrogen.

Source: scielo.br

Source: scielo.br

The purpose of this study was to explore the possibility of bleaching. Bleaching of nonwoven fabric can be done with batch or continuous systems depending on the integrity of the material. The destruction of natural coloring matter from the textile. Other processes require two or three bleaching stages. 20 million tons of Cotton is processed worldwide yearly.

Source: semanticscholar.org

Source: semanticscholar.org

20 million tons of Cotton is processed worldwide yearly. Each process will be covered in this document. The obtained results reveal that bleached cotton fabric with satisfactory whiteness index and reasonable tensile strength can be obtained by treating the fabric at 95 C in a bleaching bath containing 5 gl sodium chlorite 002 gl hexamethylenetetramine and 1 gl non-ionic wetting agent using a material to liquor ratio of 130. After scouring process bleaching is done for get white fabric. Bleaching is done for removing natural color which is inherent in the fiber.

Source: onlinelibrary.wiley.com

Source: onlinelibrary.wiley.com

Bleaching is the chemical treatment for. Typical preparation processes used for cotton and cotton blend yarns and fabrics include singeing desizing scouring bleaching mercerizing cotton only heat setting synthetic fibers only and cellulose enzyme treatments. Grey cotton fabric contains natural color and impurities on its surface. Material Well scoured cotton fabric 2 x 2 grams each Stock solution. Read article about Bleaching increase in whiteness of Cotton textile material.

Source: researchgate.net

Source: researchgate.net

And 1 gL nonionic wetting agent. To remove those impurities and improve whiteness cotton is treated with bleaching agents. Peroxide bleaching keeps the Fiber quality intact in terms of Tensile Strength. 12 gL sodium perborate. The method comprises the following operating steps.

Source: semanticscholar.org

Source: semanticscholar.org

1 Grey Desize with scour 2 Grey Scouring with bleach and 3 Desize with scour and bleach In Single Bath Process. Scouring is the process of removing the impurities such as oil fat wax dust and dirt from the textile material to make it hydrophilic. All of these except singeing and heat setting are processed using. The treatment was carried out at 60 C for 45 min. Textile pre-treatment involves desizing scouring and bleaching processes.

Source: researchgate.net

Source: researchgate.net

The method comprises the following operating steps. And Piccoli et al. Read article about Bleaching increase in whiteness of Cotton textile material. Mercerization gives a much richer and more vibrant color saturation than with unmercerized versions of the same cotton fabric. The obtained results reveal that bleached cotton fabric with satisfactory whiteness index and reasonable tensile strength can be obtained by treating the fabric at 95 C in a bleaching bath containing 5 gl sodium chlorite 002 gl hexamethylenetetramine and 1 gl non-ionic wetting agent using a material to liquor ratio of 130.

Source: researchgate.net

Source: researchgate.net

Each process requires a plethora of chemicals along with water out of which the unexhausted chemicals are drained in the. Up to 10 cash back The ozone bleaching of cotton fabrics has been studied before for example Prabaharan and Rao Perincek et al. Cotton fabric by hydrogen peroxide with varying temperature and time and analyze the effects on weight loss and whiteness and to achieve an acceptable degree of whiteness CIE whiteness index 75 with minimum. The invention discloses a method for bleaching a cotton fabric by chlorine dioxide. The optimum bleaching recipe consists of 20 gL tetraacetylethylenediamine.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title bleaching of cotton fabric pdf by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.