Your Dyeing of cotton fabric with direct dyes pdf images are ready. Dyeing of cotton fabric with direct dyes pdf are a topic that is being searched for and liked by netizens now. You can Get the Dyeing of cotton fabric with direct dyes pdf files here. Download all free images.

If you’re looking for dyeing of cotton fabric with direct dyes pdf images information related to the dyeing of cotton fabric with direct dyes pdf keyword, you have come to the ideal site. Our site frequently gives you suggestions for refferencing the highest quality video and picture content, please kindly hunt and find more enlightening video articles and graphics that fit your interests.

Dyeing Of Cotton Fabric With Direct Dyes Pdf. Nowadays reactive dyes are very popular for textile coloration because of its some specific properties like colour fastness wide range of shade brilliance of shade and simple application procedure. The dyeing process is one of the key factors in the successful trading of textile products. Dyeing for long time makes the dye 20 molecules to enter into the interior of the fabric and distribute 0 themselves. Direct dyeing process is comparatively cheap compared with reactive dye and vat dye.

Pdf Textile Softeners On Cotton Dyed With Direct Dyes Reflectance And Fastness Assessments From researchgate.net

Pdf Textile Softeners On Cotton Dyed With Direct Dyes Reflectance And Fastness Assessments From researchgate.net

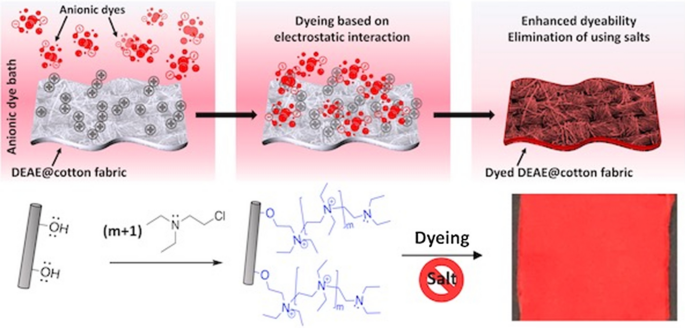

Anionic dyes such as direct reactive acid and solubilized sulfur dyes are attracted by the cationic. Nowadays reactive dyes are very popular for textile coloration because of its some specific properties like colour fastness wide range of shade brilliance of shade and simple application procedure. One-bath dyeing of cotton-nylon mixture with reactive and acid dyes was mentioned by hang Run- S ling. Hence the optimum temperature for dyeing 100 80 of irradiated cotton 2 kGy was found to be 60 1C. Colorfastness tests on cationic cotton dyed with direct or reactive dyes have shown results as good as or better than conventional dyeing of untreated cotton except for perspiration fastness. The material is washed with water 4202012 Dr.

Concentration of these dyes are unknown.

Dyeing of direct dye is carried out at 90-100oC for 1-2hrs MATERIAL TO LIQUOR RATIO MLR is a function of Machine the machine being used. Dyeablitity of cationized cotton and a nylon 6 fabric using acid dyes was described by Badawy et al. They produce full shades on cotton and linen without mordanting and can also be applied to rayon silk and wool. Introduction Reactive dyes are probably the most popular class of dyes to produce fast dyeing on piece goods. The materials which impart the color are known as colorants. The fabric was folded according to the patterns designed to appear on the fabric surface 2.

Source: mdpi.com

Source: mdpi.com

Concentration of these dyes are unknown. The materials which impart the color are known as colorants. Dyeing of direct dye is carried out at 90-100oC for 1-2hrs MATERIAL TO LIQUOR RATIO MLR is a function of Machine the machine being used. Dyeing of Cotton with Reactive Dye Prepared By. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes.

Source: researchgate.net

Source: researchgate.net

2012000400038 19th Batch Textile Department. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. They produce full shades on cotton and linen without mordanting and can also be applied to rayon silk and wool. Direct Dye is a class of dyestuff that are applied directly to the substrate in a neutral or alkaline bath. Dyes for Cellulosic Fibres Direct Dyes Cheap Produce all types of colour Can be applied easily Washing fastness is poor.

Source: researchgate.net

Source: researchgate.net

Ad Free 2-day Shipping On Millions of Items. Dyeing of Cotton with Reactive Dye Prepared By. In a reactive dye a chromophore contains a substituent that reacts with the substrate. The bond between dye molecule and fiber may be strong or weak depending on the dye used. Pigments Dyes Sulphur Dyes 5.

Source: fi.pinterest.com

Source: fi.pinterest.com

Dyeing of direct dye is carried out at 90-100oC for 1-2hrs MATERIAL TO LIQUOR RATIO MLR is a function of Machine the machine being used. Colorfastness tests on cationic cotton dyed with direct or reactive dyes have shown results as good as or better than conventional dyeing of untreated cotton except for perspiration fastness. When these colorants have a natural affinity and permanence on textiles they are referred to as dyes. Indigo is the dye used to make blue jeans blue. Dyeing off 100 cotton knit fabric with reactive dye.

Source: researchgate.net

Source: researchgate.net

Reactive Dyes 1956 UK. Oxidation Colours Solubilised Vat 4. The materials which impart the color are known as colorants. Dyeing for long time makes the dye 20 molecules to enter into the interior of the fabric and distribute 0 themselves. Printing of cotton fabric with reactive dyes Screen.

Source: textilesphere.com

Source: textilesphere.com

The fabric was folded according to the patterns designed to appear on the fabric surface 2. It is a cationic dye. Indigo is the dye used to make blue jeans blue. Tanvir Ahammed Rana Id. The materials which impart the color are known as colorants.

Source: pinterest.com

Source: pinterest.com

Tanvir Ahammed Rana Id. In this experiment indigo dye will be used to dye a sample of cotton fabric. In a reactive dye a chromophore contains a substituent that reacts with the substrate. Ad Colorants for all Types of Fabric Acid Basic Reactive Vat Dyes. 23 Dyeing of cotton fabrics The dyeing process of the fabric was done using a method called tie and dye method and the method is described hereunder.

Source: pinterest.com

Source: pinterest.com

Full PDF Package Download Full. Indigo Materials Needed 6 beakers 400 mL beaker 20 mL or 50 mL Erlenmeyer flask 125 mL with stopper. In a reactive dye a chromophore contains a substituent that reacts with the substrate. It is a cationic dye. One-bath dyeing of cotton-nylon mixture with reactive and acid dyes was mentioned by hang Run- S ling.

Source: pinterest.com

Source: pinterest.com

Reactive Dyes 1956 UK. Printing of cotton fabric with reactive dyes Screen. 23 Dyeing of cotton fabrics The dyeing process of the fabric was done using a method called tie and dye method and the method is described hereunder. When these colorants have a natural affinity and permanence on textiles they are referred to as dyes. Introduction Reactive dyes are probably the most popular class of dyes to produce fast dyeing on piece goods.

Source: pinterest.com

Source: pinterest.com

Direct dye have good affinity for cellulosic materials and as well as proteins fibres. Full PDF Package Download Full. Direct dyeing in which the dye in the aqueous solution is in contact with the material and is gradually absorbed into the fibers because of the inherent substantivity. Request PDF Dyeing of cotton fabric with antibacterial properties using direct dye and CTAB Direct dyes still represent an important class of dye for use on cellulose fiber because of the. 23 Dyeing of cotton fabrics The dyeing process of the fabric was done using a method called tie and dye method and the method is described hereunder.

Source: pinterest.com

Source: pinterest.com

TEMPERATURE For all direct dyes there is an optimum temperature Example- CIDirect yellow 12 20oC CIDirect Red 8160oC CIDirect Yellow 28100oC Many shades are obtained by mixing 2-3 dyes. In a reactive dye a chromophore contains a substituent that reacts with the substrate. Pigments Dyes Sulphur Dyes 5. They produce full shades on cotton and linen without mordanting and can also be applied to rayon silk and wool. Reactive Dyes 1956 UK.

Source: researchgate.net

Source: researchgate.net

Direct dyeing in which the dye in the aqueous solution is in contact with the material and is gradually absorbed into the fibers because of the inherent substantivity. 2012000400038 19th Batch Textile Department. The fabric was folded according to the patterns designed to appear on the fabric surface 2. Effects of alkali proteases on dyeing characteristics of different proteinous materials with natural dyes were examined by Kumbasar et al. The dyeing process is one of the key factors in the successful trading of textile products.

Source: pinterest.com

Source: pinterest.com

Dyes for Cellulosic Fibres Direct Dyes Cheap Produce all types of colour Can be applied easily Washing fastness is poor. Dyeing of cotton with reactive dye 1. The materials which impart the color are known as colorants. 60 The dyeing of cotton fabric with stilbene based direct dye is 40 also time dependent. Ad Colorants for all Types of Fabric Acid Basic Reactive Vat Dyes.

Source: researchgate.net

Source: researchgate.net

Direct Dye is a class of dyestuff that are applied directly to the substrate in a neutral or alkaline bath. Tanvir Ahammed Rana Id. Indigo Materials Needed 6 beakers 400 mL beaker 20 mL or 50 mL Erlenmeyer flask 125 mL with stopper. Ad Colorants for all Types of Fabric Acid Basic Reactive Vat Dyes. Nowadays reactive dyes are very popular for textile coloration because of its some specific properties like colour fastness wide range of shade brilliance of shade and simple application procedure.

Source: researchgate.net

Source: researchgate.net

Ad Free 2-day Shipping On Millions of Items. One-bath dyeing of cotton-nylon mixture with reactive and acid dyes was mentioned by hang Run- S ling. Dyes for Cellulosic Fibres Direct Dyes Cheap Produce all types of colour Can be applied easily Washing fastness is poor. Dyeing of cotton with reactive dye 1. Introduction Reactive dyes are probably the most popular class of dyes to produce fast dyeing on piece goods.

Source: anyflip.com

Source: anyflip.com

In this experiment indigo dye will be used to dye a sample of cotton fabric. The materials which impart the color are known as colorants. Dyeing of direct dye is carried out at 90-100oC for 1-2hrs MATERIAL TO LIQUOR RATIO MLR is a function of Machine the machine being used. One-bath dyeing of cotton-nylon mixture with reactive and acid dyes was mentioned by hang Run- S ling. The material is washed with water 4202012 Dr.

Source: link.springer.com

Source: link.springer.com

Reactive dyes have good fastness properties owing to the bonding that occurs during dyeing. Nowadays reactive dyes are very popular for textile coloration because of its some specific properties like colour fastness wide range of shade brilliance of shade and simple application procedure. Direct dye have good affinity for cellulosic materials and as well as proteins fibres. Dyeing of 100 cotton knitted fabric with direct dye. In addition to the design and beautiful color the consumer usually looks for some basic prod uct characteristics such as good fixation with respect to light perspiration and washing Textile Dyes.

Source: academia.edu

Source: academia.edu

TEMPERATURE For all direct dyes there is an optimum temperature Example- CIDirect yellow 12 20oC CIDirect Red 8160oC CIDirect Yellow 28100oC Many shades are obtained by mixing 2-3 dyes. Request PDF Dyeing of cotton fabric with antibacterial properties using direct dye and CTAB Direct dyes still represent an important class of dye for use on cellulose fiber because of the. Anionic dyes such as direct reactive acid and solubilized sulfur dyes are attracted by the cationic. One-bath dyeing of cotton-nylon mixture with reactive and acid dyes was mentioned by hang Run- S ling. In a reactive dye a chromophore contains a substituent that reacts with the substrate.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title dyeing of cotton fabric with direct dyes pdf by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.