Your Dyeing process of cotton fabric with reactive dye images are available. Dyeing process of cotton fabric with reactive dye are a topic that is being searched for and liked by netizens today. You can Get the Dyeing process of cotton fabric with reactive dye files here. Find and Download all royalty-free vectors.

If you’re searching for dyeing process of cotton fabric with reactive dye images information related to the dyeing process of cotton fabric with reactive dye interest, you have visit the ideal blog. Our site frequently gives you hints for refferencing the highest quality video and image content, please kindly surf and find more enlightening video content and graphics that match your interests.

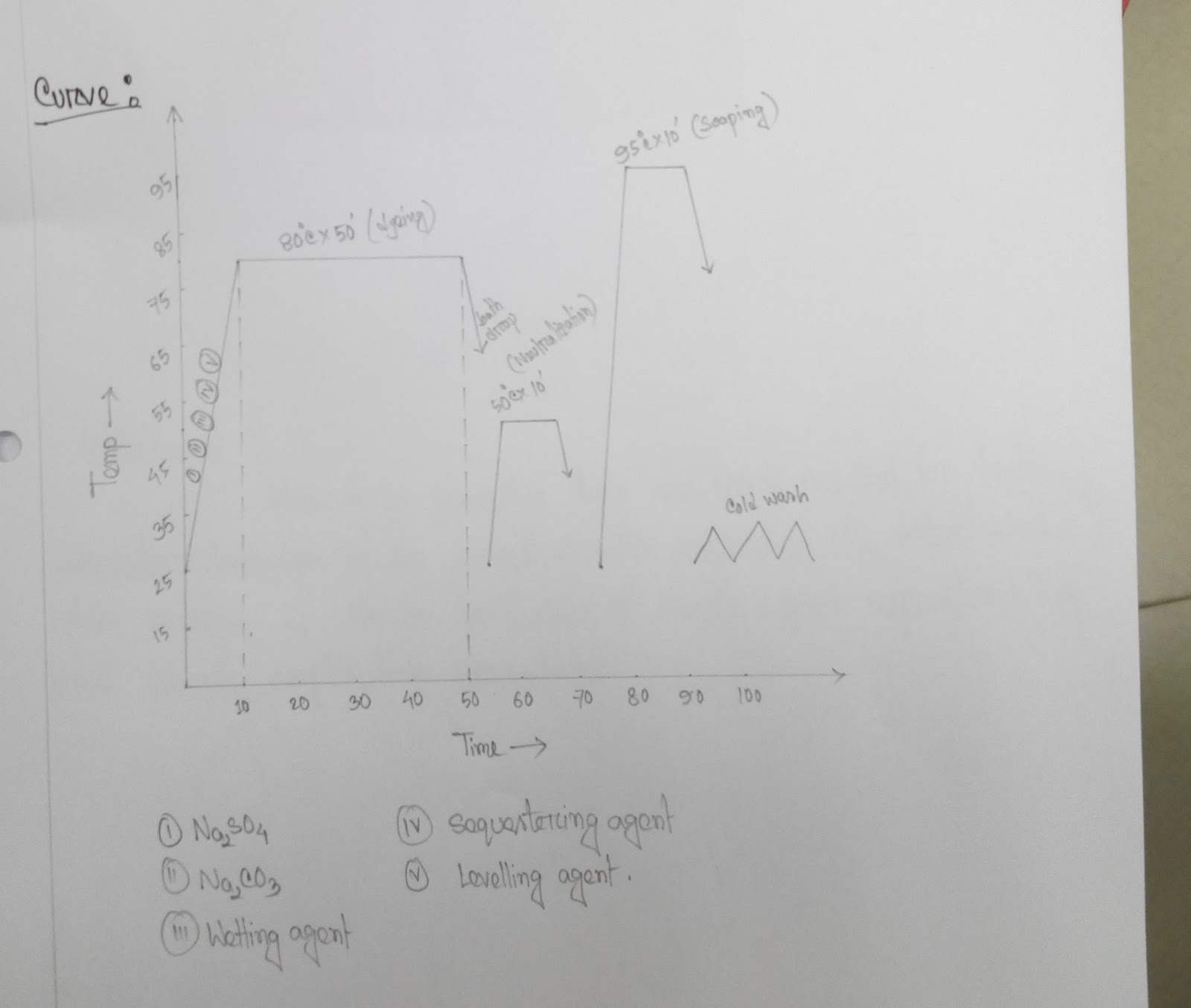

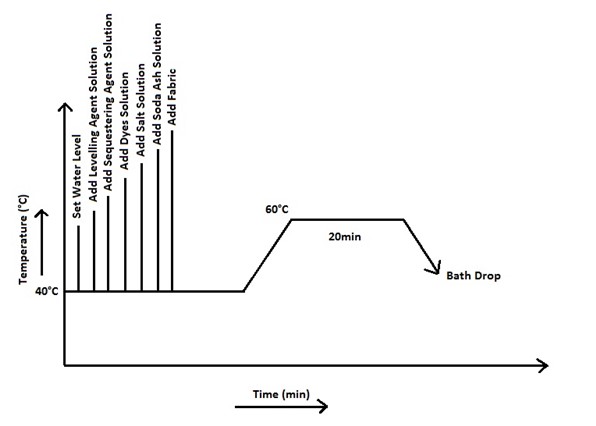

Dyeing Process Of Cotton Fabric With Reactive Dye. In addition to the design and beautiful color the consumer usually looks for some basic prod uct characteristics such as good fixation with respect to light perspiration and washing Textile Dyes. To make it easy for you we have a range of 100 cotton ethically made items to dye on our website just go to the Ready to Dye page or choose a few items from this page at a special price. Dyeing Process and Environmental. Dye exhaustion or dye fixation.

Pdf Dyeing Of Cotton Fabric With Reactive Dyes And Their Physico Chemical Properties From researchgate.net

Pdf Dyeing Of Cotton Fabric With Reactive Dyes And Their Physico Chemical Properties From researchgate.net

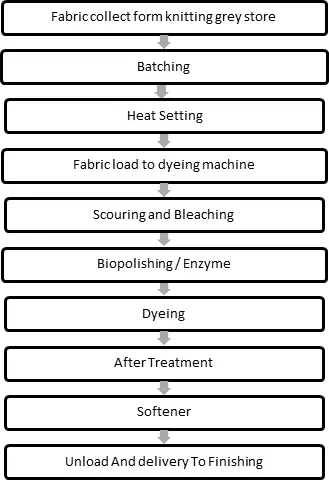

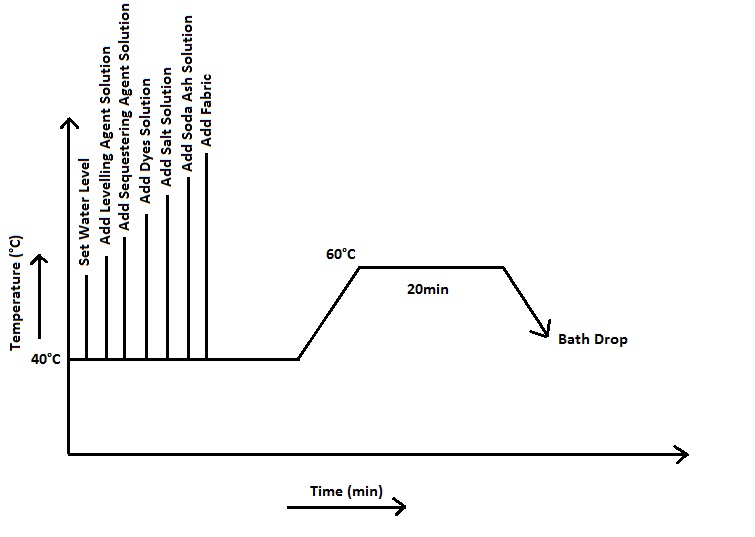

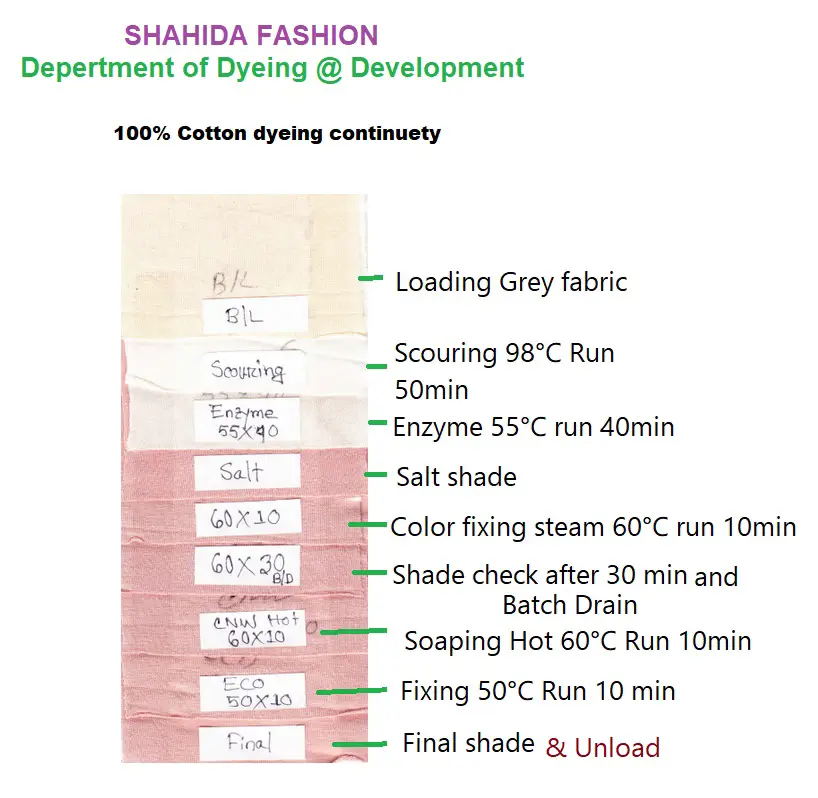

Non-cellouse materials oil fat and wax. Fibre-reactive dyes are dyes that bond to the fibre due to a chemical reaction with fabrics like cotton rayon and soy. Dyeing is the application of dyes or pigments on textile materials such as fibers yarns and fabrics with the goal of achieving color with desired color fastnessDyeing is normally done in a special solution containing dyes and particular chemical material. Dyeing performance of fabric depends on the process bleaching. They are Sydneys premier dyeing service. Bleaching is used to reduce natural color of the raw materials.

If youre looking for a dyeing company down-under this is the place to go.

These are usually used to dye cellulosic fibers such as cotton rayon or flax but polyamide wool silk and acetate fibers can. It is inexpensive and has good wash-fastness. The Color Fastness to wet rubbing of reactive dye-dyed fabrics is closely related to the depth of dyeing in the sense that when wet rubbing the amount of color transfer and the depth of dyeing are almost in a good linear relationship. Fibre-reactive dyes are dyes that bond to the fibre due to a chemical reaction with fabrics like cotton rayon and soy. The process of applying color to fiber stock yarn or fabric is called dyeingThere may or may not be thorough penetration of the colorant into the fibers or yarns. Rinse the fabric in another bucket of clean water.

Source: practicaltextile.com

Source: practicaltextile.com

Sabracron F Reactive Dyes can be kept in solution without fixative for two weeks at room temperature. They are Sydneys premier dyeing service. There have been attempts to apply reactive dyes to indigo machines but dye control is nearly impossible due to the large dye boxes in most indigo equipment as much of the dye is decomposed before it interacts with the cotton. The process increased the fabric absorbency and luster of the fabric dying and printing. Reactive dyes are mainly used for dyeing cellulose fibres such as cotton and viscose but they are also increasingly gaining importance for wool and polyamide.

Source: researchgate.net

Source: researchgate.net

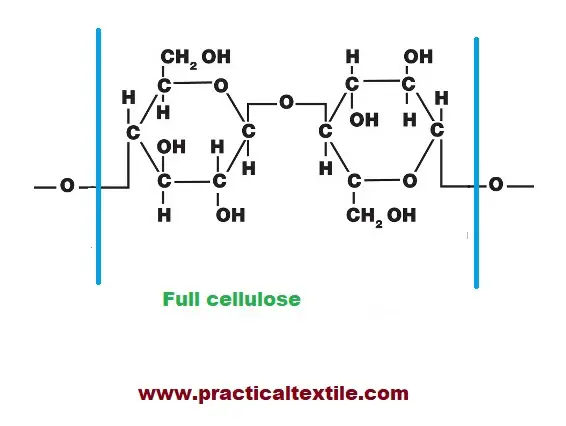

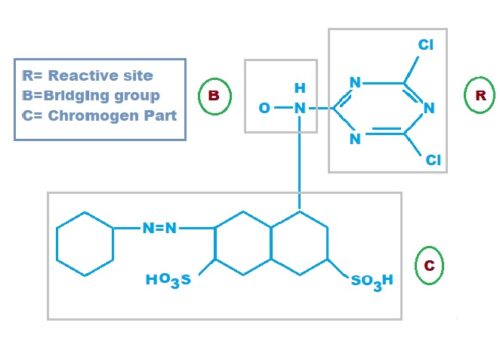

Reactive dye is a class of dye that makes a covalent bond with the fiber and becomes an integral part of the fiber. Request a FREE catalog with everything you need for home or. That is why the dyes are so permanent and vibrant even after several washings. Although almost all dyeing can be done in a vat the term vat dye is used to describe a chemical class of dyes that are applied to cellulosic fibre ie cotton using a redox reaction as described belowBecause of the use of caustic soda and the very high pH of the dye bath in the dyeing process wool cannot be dyed using vat dyestuffs. Excessive dyes cannot be combined entirely with fibers.

Source: practicaltextile.com

Source: practicaltextile.com

Their services include dyeing shirts jeans suits coats curtains and any other type of apparel. Dyeing performance of fabric depends on the process bleaching. Materials suited for vat dyeing. Dharma Trading Company has been a supplier of fiber arts supplies for more than 40 years. Scouring is the first procedure for any dyeing process.

Source: diutestudents.blogspot.com

Source: diutestudents.blogspot.com

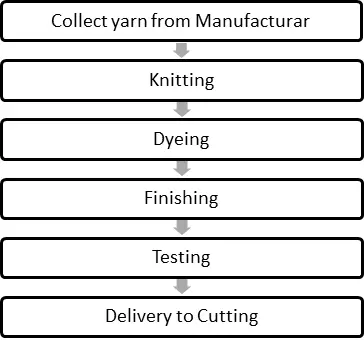

What is the science behind tie-dye. Reactive dye is a class of dye that makes a covalent bond with the fiber and becomes an integral part of the fiber. Actually good quality fabric production involves dyeing at the yarn stage as the colors will not fade much. That means a chemical reaction takes place between the dye molecules and the fabric molecules. It is then piece-dyed.

Source: researchgate.net

Source: researchgate.net

You can determine the darkness of the dye by increasing the number of pods boiled. What is the science behind tie-dye. The dye bonds with the cotton and actually becomes a part of the fabric. However the modern natural dyeing process information is very insufficient. Squeeze out all the water before submerging it into the indigo dye bath.

Source: scirp.org

Source: scirp.org

Gently manipulate and massage the dye into the fabric. Scouring removed natural impurities such as. Two ounces 58 gm of dye will color 14 yards 13 meters of cotton muslin to a medium in a solid shade dye bath or 12 T-Shirts for tie dye. Just remember you can only dye plant-based fabric eg Cotton bamboo linen rayon hemp. Fibre-reactive dyes are dyes that bond to the fibre due to a chemical reaction with fabrics like cotton rayon and soy.

Source: semanticscholar.org

Source: semanticscholar.org

The range of available reactive dyes is wide and enables a large number of dyeing techniques to be used. The dyes are called fiber-reactive. They are Sydneys premier dyeing service. There have been attempts to apply reactive dyes to indigo machines but dye control is nearly impossible due to the large dye boxes in most indigo equipment as much of the dye is decomposed before it interacts with the cotton. Dyeing and printing processes are value-added treatments for most textile materials.

Source: fibre2fashion.com

Source: fibre2fashion.com

In addition to the design and beautiful color the consumer usually looks for some basic prod uct characteristics such as good fixation with respect to light perspiration and washing Textile Dyes. Therefore reactive dyes should be placed in a small box then dried chemically primed and evaporated. Just remember you can only dye plant-based fabric eg Cotton bamboo linen rayon hemp. That is why the dyes are so permanent and vibrant even after several washings. The dye bonds with the cotton and actually becomes a part of the fabric.

Source: practicaltextile.com

Source: practicaltextile.com

If youre looking for a way to update your dark clothes try tie dyeing with bleach. There have been attempts to apply reactive dyes to indigo machines but dye control is nearly impossible due to the large dye boxes in most indigo equipment as much of the dye is decomposed before it interacts with the cotton. Dyeing is the application of dyes or pigments on textile materials such as fibers yarns and fabrics with the goal of achieving color with desired color fastnessDyeing is normally done in a special solution containing dyes and particular chemical material. After about 5 minutes take the fabric out of. That means a chemical reaction takes place between the dye molecules and the fabric molecules.

Source: semanticscholar.org

Source: semanticscholar.org

The dye bonds with the cotton and actually becomes a part of the fabric. Two ounces 58 gm of dye will color 14 yards 13 meters of cotton muslin to a medium in a solid shade dye bath or 12 T-Shirts for tie dye. However the modern natural dyeing process information is very insufficient. Dharma Trading Company has been a supplier of fiber arts supplies for more than 40 years. Dyeing process The dyeing process is one of the key factors in the successful trading of textile products.

Source: researchgate.net

Source: researchgate.net

Dye exhaustion or dye fixation. Gently manipulate and massage the dye into the fabric. Scouring removed natural impurities such as. Scouring is the first procedure for any dyeing process. Again try not to agitate the dye by working gently under the surface of the dye.

Source: textileanalysis.blogspot.com

Source: textileanalysis.blogspot.com

There have been attempts to apply reactive dyes to indigo machines but dye control is nearly impossible due to the large dye boxes in most indigo equipment as much of the dye is decomposed before it interacts with the cotton. Reactive dye is a class of dye that makes a covalent bond with the fiber and becomes an integral part of the fiber. When boiled they will produce a dark gray dye for cotton fabrics. The Color Fastness to wet rubbing of reactive dye-dyed fabrics is closely related to the depth of dyeing in the sense that when wet rubbing the amount of color transfer and the depth of dyeing are almost in a good linear relationship. Coloring using these dyes does not require mordants.

Source: diutestudents.blogspot.com

Source: diutestudents.blogspot.com

The range of available reactive dyes is wide and enables a large number of dyeing techniques to be used. The dye bonds with the cotton and actually becomes a part of the fabric. Therefore reactive dyes should be placed in a small box then dried chemically primed and evaporated. Their services include dyeing shirts jeans suits coats curtains and any other type of apparel. Reactive dyes are the best fabric dye choice for cotton and other cellulose fibers at home.

Source: practicaltextile.com

Source: practicaltextile.com

Excessive dyes cannot be combined entirely with fibers. Influence of reactive dyeing degree. The mass of dye taken up by the yarn or fabric divided by the total initial mass of dye in the water bath. Scouring removed natural impurities such as. In addition to the design and beautiful color the consumer usually looks for some basic prod uct characteristics such as good fixation with respect to light perspiration and washing Textile Dyes.

Source: practicaltextile.com

Source: practicaltextile.com

Reactive dyes are mainly used for dyeing cellulose fibres such as cotton and viscose but they are also increasingly gaining importance for wool and polyamide. Youll get a cool white design that stands out well against dark or bright colors. In addition to the design and beautiful color the consumer usually looks for some basic prod uct characteristics such as good fixation with respect to light perspiration and washing Textile Dyes. That is why an attempt has been made here to give a scientific overview of the dyeing process. Our dyes wont dye man-made fibres eg.

Source: scielo.org.mx

Source: scielo.org.mx

That is why the dyes are so permanent and vibrant even after several washings. Although almost all dyeing can be done in a vat the term vat dye is used to describe a chemical class of dyes that are applied to cellulosic fibre ie cotton using a redox reaction as described belowBecause of the use of caustic soda and the very high pH of the dye bath in the dyeing process wool cannot be dyed using vat dyestuffs. Dyeing process The dyeing process is one of the key factors in the successful trading of textile products. They dye acrylic polyester nylon and all natural fibers. Dyeing Process and Environmental.

Source: researchgate.net

Source: researchgate.net

Dye exhaustion or dye fixation. Dye molecules are fixed to the fiber by absorption diffusion or bonding with temperature and time being key controlling factors. That is why an attempt has been made here to give a scientific overview of the dyeing process. Their services include dyeing shirts jeans suits coats curtains and any other type of apparel. Dharma Trading Company has been a supplier of fiber arts supplies for more than 40 years.

Source: diutestudents.blogspot.com

Source: diutestudents.blogspot.com

Bleaching is used to reduce natural color of the raw materials. When boiled they will produce a dark gray dye for cotton fabrics. Dharma Trading Company has been a supplier of fiber arts supplies for more than 40 years. Rinse the fabric in another bucket of clean water. Different methods like Reactive Pigment Discharge Burnout Rotary or Flat Screens are used to dye fabrics.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title dyeing process of cotton fabric with reactive dye by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.