Your Enzymatic desizing of cotton fabric images are available in this site. Enzymatic desizing of cotton fabric are a topic that is being searched for and liked by netizens now. You can Find and Download the Enzymatic desizing of cotton fabric files here. Find and Download all royalty-free images.

If you’re searching for enzymatic desizing of cotton fabric images information related to the enzymatic desizing of cotton fabric keyword, you have pay a visit to the right blog. Our site frequently gives you hints for refferencing the maximum quality video and picture content, please kindly search and find more informative video content and graphics that fit your interests.

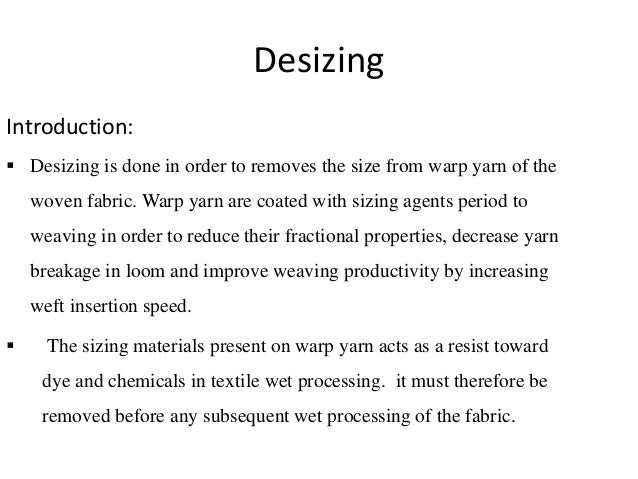

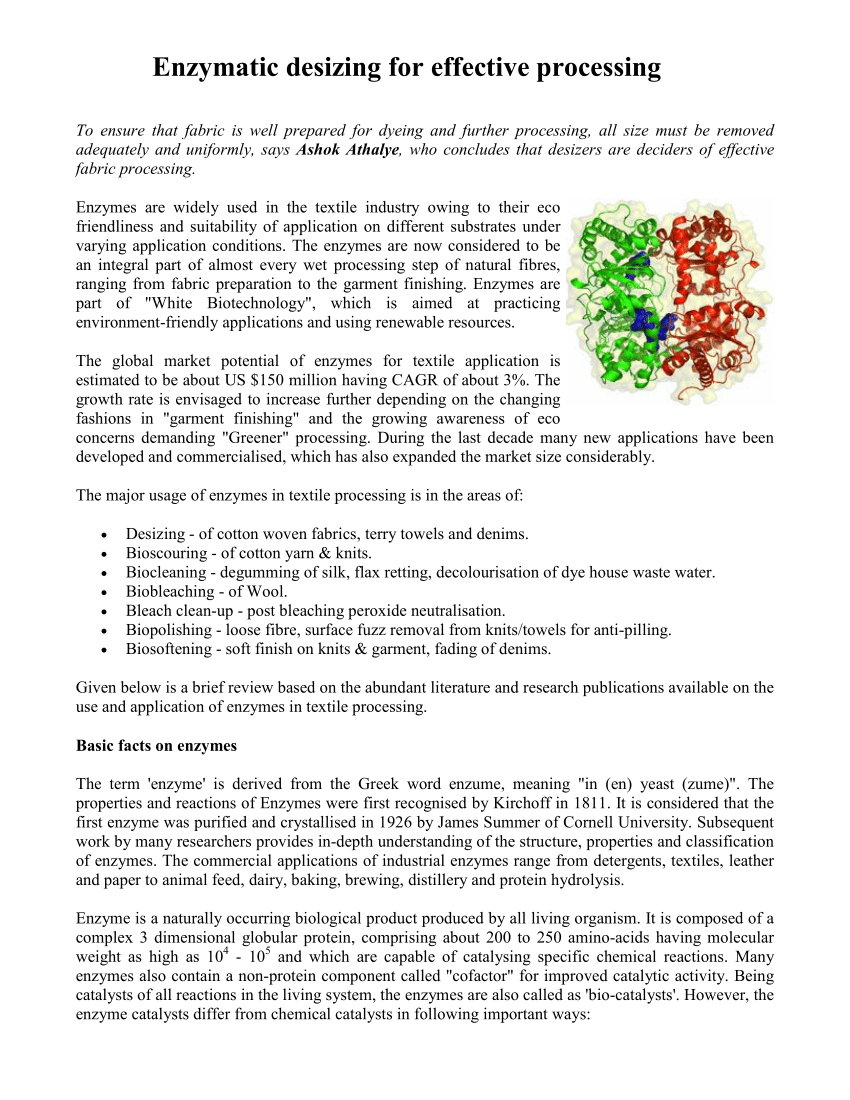

Enzymatic Desizing Of Cotton Fabric. After desizing the fabric is squeezed and stored in a storage tank. Connecting Threads Shop Now. Closely constructed fabric can be easily desized due to the effective enzyme action. From this point of view new efficient strategies for cotton wet processing are It is a complex process and its complexity depends on the composition of textile material.

Effect Of Temperature A And Ph B On Desizing Efficiency Weight Download Scientific Diagram From researchgate.net

Effect Of Temperature A And Ph B On Desizing Efficiency Weight Download Scientific Diagram From researchgate.net

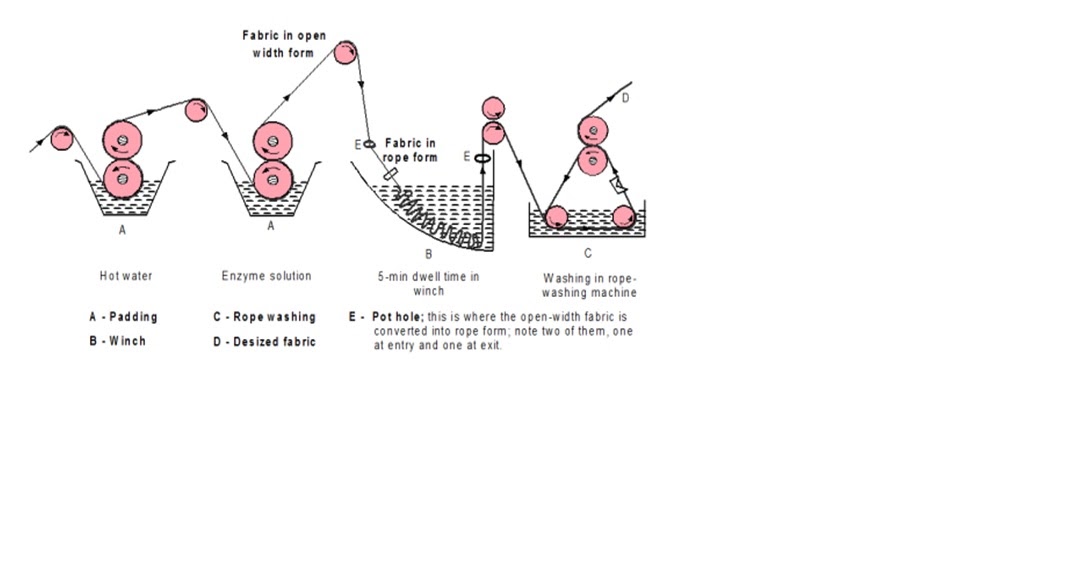

Enzymatic desizing is the classical desizing process of degrading starch size on cotton fabrics using enzymes. Then the fabric is immersed into the desizing liquor. In the present investigation multi-response optimization in enzymatic desizing of cotton fabric against various chemo-physical conditions was carried out. Enzymes are complex organic soluble bio-catalysts formed by living organisms that catalyze chemical reaction in biological processes. Finally cold wash is carried out and then squeezed and dried. Enzymatic desizing is the classical desizing process of degrading starch size on cotton fabrics using enzymes.

Enzymatic desizing Disadvantages.

Enzymatic desizing is the classical desizing process of degrading starch size on cotton fabrics using enzymes. Application of the enzyme digestion of the starch and removal of the digestion products. Ad Find Quilting Fabric For Sale Online By The Yard As Well As In Precuts and Quilt Kits. Fabric samples were desized by. Other natural fibers are also treated with enzymes. Enzymatic desizing of cotton with α-amylases is state-of-the-art since many decades 4.

Source: definetextile.com

Source: definetextile.com

Ad Find Quilting Fabric For Sale Online By The Yard As Well As In Precuts and Quilt Kits. The ultrasound aided enzymatic desizing conditions of cotton were optimized. The common components of an enzymatic desizing bath are. Enzymes are multipart organic soluble bio-catalysts created by living organisms that catalyze chemical effect in a biological process. The temperature of the liquor is raised to 50-60ºC and run for 1 hour.

Source: ordnur.com

Source: ordnur.com

Enzymatic desizing is the classical desizing process of degrading starch size on cotton fabrics using enzymes. This study aims to optimize the enzymatic desizing of cotton fabric using a metal and Ca2 ionindependent alpha-amylase from Bacillus sp. Ad Shop Fabric From Etsy To Unleash Your Creative Side. Enzymatic desizing Advantages Time required for the desizing process is less. The ultrasound aided enzymatic desizing conditions of cotton were optimized.

Source: chimeratextiles.com

Source: chimeratextiles.com

Enzymatic desizing Disadvantages. KR-8104 that is highly active under acidic conditions. Then the fabric is immersed into the desizing liquor. An outstanding feature of enzyme desizing is the specific nature of the enzyme action. In the present investigation multi-response optimization in enzymatic desizing of cotton fabric against various chemo-physical conditions was carried out.

Source: researchgate.net

Source: researchgate.net

Highlights Enzymatic treatment of cotton fabric is a nontoxic and eco-friendly process. Closely constructed fabric can be easily desized due to the effective enzyme action. This is especially evident in the processing of cotton garments and fabrics where cellulase enzymes are used to enhance cotton products without adversely affecting the environment. From this point of view new efficient strategies for cotton wet processing are It is a complex process and its complexity depends on the composition of textile material. PDF One-Step Process for Enzymatic Desizing and Bioscouring of Cotton Fabrics Magdy K Zahran -.

Source: youtube.com

Source: youtube.com

The optimum desizing in terms of weight loss and Tegewa violet scale was obtained at 60 C pH 56 for 30 min in the presence of 45 IU of α-amylase. We Have The Supplies And Tools Just For You. Enzymatic desizing Disadvantages. Closely constructed fabric can be easily desized due to the effective enzyme action. Enzymes are complex organic soluble bio-catalysts formed by living organisms that catalyze chemical reaction in biological processes.

Source: textilechemrose.blogspot.com

Source: textilechemrose.blogspot.com

Finally cold wash is carried out and then squeezed and dried. After desizing the fabric is squeezed and stored in a storage tank. Cotton fabrics sized with a PVA solution 25 g dm 3 were desized with the enzyme mixture after a 1 h treatment at 30C and pH 80. Therefore enzyme desizing is safer than acid desizing where cellulose may also get hydrolysed if the concentration of the acid is higher than the optimum value. Thus diastase hydrolyses starch but does not tender cellulose.

Source: researchgate.net

Source: researchgate.net

Highlights Enzymatic treatment of cotton fabric is a nontoxic and eco-friendly process. Quality Quilt Fabrics and Supplies From The Best Manufacturers and Brands. Enzymatic desizing Disadvantages. Therefore enzyme desizing is safer than acid desizing where cellulose may also get hydrolysed if the concentration of the acid is higher than the optimum value. Other natural fibers are also treated with enzymes.

Source: sciencedirect.com

Source: sciencedirect.com

Highlights Enzymatic treatment of cotton fabric is a nontoxic and eco-friendly process. From this point of view new efficient strategies for cotton wet processing are It is a complex process and its complexity depends on the composition of textile material. Finally cold wash is carried out and then squeezed and dried. Quality Quilt Fabrics and Supplies From The Best Manufacturers and Brands. In this case similar amounts of residual PVA in fabrics were detected in comparison with the conventional desizing process which uses hot water 80C 30 min.

Source: sciencedirect.com

Source: sciencedirect.com

KR-8104 that is highly active under acidic conditions. It is continuous process so greater production can be achieved. Fabric samples were desized by. Common Problems in Enzymatic Desizing Incomplete desizing It occurs due to inadequate enzyme improper desizing bath. In the present investigation multi-response optimization in enzymatic desizing of cotton fabric against various chemo-physical conditions was carried out.

Source: slideshare.net

Source: slideshare.net

After desizing the fabric is squeezed and stored in a storage tank. Closely constructed fabric can be easily desized due to the effective enzyme action. Therefore enzyme desizing is safer than acid desizing where cellulose may also get hydrolysed if the concentration of the acid is higher than the optimum value. Enzymatic desizing is the classical desizing process of degrading starch size on cotton fabrics using enzymes. From this point of view new efficient strategies for cotton wet processing are It is a complex process and its complexity depends on the composition of textile material.

Source: fibre2fashion.com

Source: fibre2fashion.com

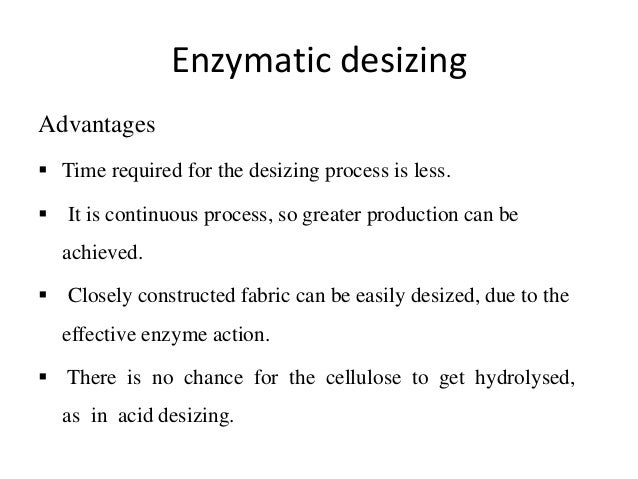

Abstract In this experiment 100 cotton fabric was desizedI used exhaust method to desize the cotton fabric in which enzymes and wetting agent were used simultaneously for desizing of cotton fabric. Enzymatic desizing is a traditional desizing procedure of degrading starch size on cotton fabrics using enzymes. Over the last two decades enzyme technology in the textile industry has expanded dramatically. This is especially evident in the processing of cotton garments and fabrics where cellulase enzymes are used to enhance cotton products without adversely affecting the environment. Enzymes are quite specific in their action on a particular substance.

Source: slideshare.net

Source: slideshare.net

From this point of view new efficient strategies for cotton wet processing are It is a complex process and its complexity depends on the composition of textile material. Abstract In this experiment 100 cotton fabric was desizedI used exhaust method to desize the cotton fabric in which enzymes and wetting agent were used simultaneously for desizing of cotton fabric. The common components of an enzymatic desizing bath are. This is especially evident in the processing of cotton garments and fabrics where cellulase enzymes are used to enhance cotton products without adversely affecting the environment. Finally cold wash is carried out and then squeezed and dried.

Ad Find Quilting Fabric For Sale Online By The Yard As Well As In Precuts and Quilt Kits. Therefore enzyme desizing is safer than acid desizing where cellulose may also get hydrolysed if the concentration of the acid is higher than the optimum value. Ad Shop Fabric From Etsy To Unleash Your Creative Side. Out of these methods enzymatic desizing is commercially utilized in the process houses of textile industries for removal of starch from the sized cotton substrates23 The desizing of cotton with. An outstanding feature of enzyme desizing is the specific nature of the enzyme action.

Source: researchgate.net

Source: researchgate.net

Enzymes are complex organic soluble bio-catalysts formed by living organisms that catalyze chemical reaction in biological processes. Enzymes are quite specific in their action on a particular substance. Thus diastase hydrolyses starch but does not tender cellulose. Enzymatic desizing of cotton with α-amylases is state-of-the-art since many decades 4. Ad Find Quilting Fabric For Sale Online By The Yard As Well As In Precuts and Quilt Kits.

After desizing the fabric is squeezed and stored in a storage tank. Enzymatic desizing Advantages Time required for the desizing process is less. Ad We Love Quilting As Much As You Do. Moreover cellulases pectinases hemicellulases lipases and catalases are used in different cotton pre-treatment and finishing processes 5. Then the fabric is immersed into the desizing liquor.

Source: textilesphere.com

Source: textilesphere.com

Moreover cellulases pectinases hemicellulases lipases and catalases are used in different cotton pre-treatment and finishing processes 5. Cotton fabrics sized with a PVA solution 25 g dm 3 were desized with the enzyme mixture after a 1 h treatment at 30C and pH 80. We Have The Supplies And Tools Just For You. PDF One-Step Process for Enzymatic Desizing and Bioscouring of Cotton Fabrics Magdy K Zahran -. Title To observe the effect of pH on enzyme desizing of 100 cotton fabric.

Source: researchgate.net

Source: researchgate.net

Enzymatic desizing Advantages Time required for the desizing process is less. It is continuous process so greater production can be achieved. Enzymatic desizing is the classical desizing process of degrading starch size on cotton fabrics using enzymes. Connecting Threads Shop Now. Enzymatic desizing Advantages Time required for the desizing process is less.

Source: sciencedirect.com

Source: sciencedirect.com

Moreover cellulases pectinases hemicellulases lipases and catalases are used in different cotton pre-treatment and finishing processes 5. Ultrasonic can accelerate the overall reaction rate between enzyme and substrate. Every enzyme has particular effect on grey fabric at a particular pH. Ultrasonic energy could improve the efficiency of enzymatic desizing. Enzymes are complex organic soluble bio-catalysts formed by living organisms that catalyze chemical reaction in biological processes.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title enzymatic desizing of cotton fabric by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.