Your How much process flow chart of cotton fabric in bangladesh images are available. How much process flow chart of cotton fabric in bangladesh are a topic that is being searched for and liked by netizens now. You can Download the How much process flow chart of cotton fabric in bangladesh files here. Download all royalty-free images.

If you’re looking for how much process flow chart of cotton fabric in bangladesh pictures information linked to the how much process flow chart of cotton fabric in bangladesh topic, you have come to the ideal site. Our site always gives you suggestions for refferencing the maximum quality video and image content, please kindly hunt and locate more informative video content and images that match your interests.

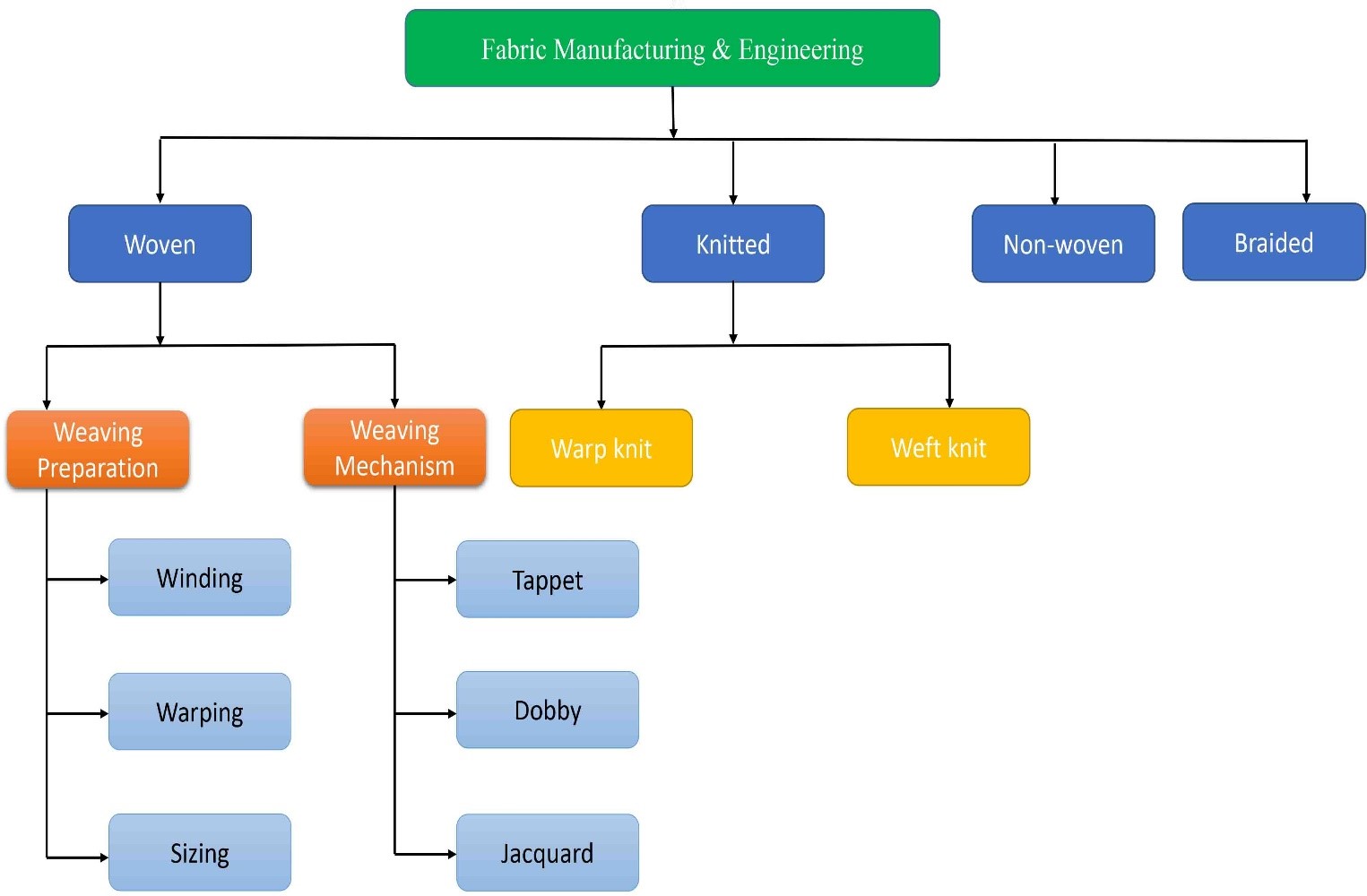

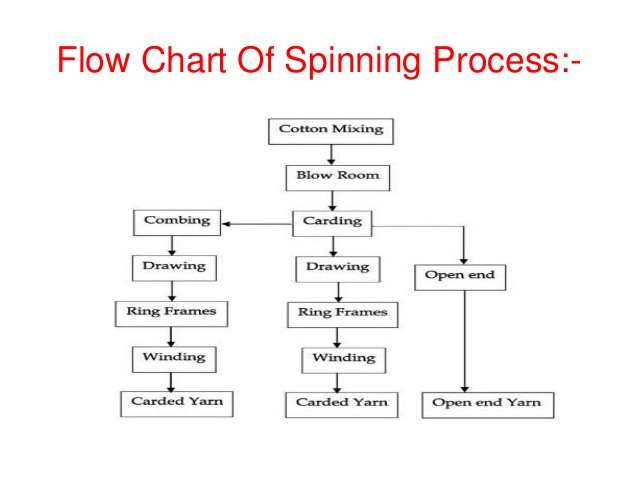

How Much Process Flow Chart Of Cotton Fabric In Bangladesh. Process flow chart of weaving technology is given below. The production capacity of this spinning factory will be depends on our requirement. The spinning process where raw cotton is turned into thread and the weaving process where the thread is woven into fabric. January 4 2021 by Mazharul Islam Kiron.

Flow Chart Of Fabric Manufacturing Te From textilecreativities.blogspot.com

Flow Chart Of Fabric Manufacturing Te From textilecreativities.blogspot.com

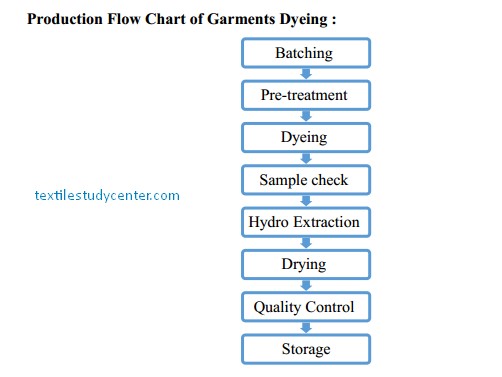

It is a fabric made of cotton twill that is 100 cotton and very comfortable. Ø 1st Step. Check the fabric if enzyme action is proper. April 30 2015 by textile-flowchart. Check the pH 34-48 of liquor. Tuft size of cotton becomes smaller in this section.

It is a fabric made of cotton twill that is 100 cotton and very comfortable.

January 4 2021 by Mazharul Islam Kiron. Luster and strength of the fabric increases for mercerizing process. June 13 2013 at 948 am. A special rubber formulation has to be made in order to apply this print to elastic material Flow chart of rubber printing process on cotton fabric 7. April 30 2015 by textile-flowchart. January 4 2021 by Mazharul Islam Kiron.

Source: researchgate.net

Source: researchgate.net

Weaving is done by the interlacement of these two types of yarn. Load the package in the carrier and feed in the vessel. The denim fabrics are woven with a coarse count high thread density and 3 1 twill weave. Working Flow Chart of Blow Room in Cotton Spinning. An ETP is under construction in Litun Fabrics Ltd.

Source: researchgate.net

Source: researchgate.net

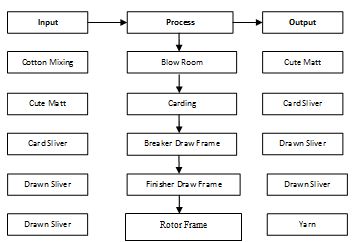

A section in which the supplied compressed bales are opened cleaned blending or mixing to form a uniform lap of specific length is called blowroom section. Here we will explain each process in detail using some illustrations. Denim is a durable cotton twill textile in which the weft passes under two or more warp threads. -List of Top 10 Denim Mills in Bangladesh-Flow Chart of Denim Manufacturing Process-Flow Chart of Denim Washing Process-Difference Between Denim and Jeans-Types of Denim Fabric Used in Garments Manufacturing-List of Top 100 Garment Buyers in Bangladesh-Top 50 Garments Buying Houses in Bangladesh-20 Woven Fabric Defects with Pictures. Weaving is done by the interlacement of these two types of yarn.

Source: researchgate.net

Source: researchgate.net

It can apply to most fabric materials in light or dark colours. Process for cotton yarn can be vary depending on the individual procedure of a textile engineer or a dyeing masterI have given a process flow chart for 100 cotton dyeing. January 4 2021 by Mazharul Islam Kiron. Flow Process chart of Jute Spinning 10. May 4 2013 at 512 am.

Source: researchgate.net

Source: researchgate.net

Spinning process is an initial step to produce textile layout such as garments fabric home textile and so. Cotton is a soft fluffy staple fiber. It is the first step of spinning. Dyeing flow chart of polyester cotton is given below. Flow chart of textile Processing Textile Fibers.

Source: prezi.com

Source: prezi.com

Process for cotton yarn can be vary depending on the individual procedure of a textile engineer or a dyeing masterI have given a process flow chart for 100 cotton dyeing. If not then increase the time. For producing the yarn at first we need to setup a spinning factory. Flow chart of jute yarn manufacturing process. Process flow chart of biological waste water treatment plant.

Source: textilestudycenter.com

Source: textilestudycenter.com

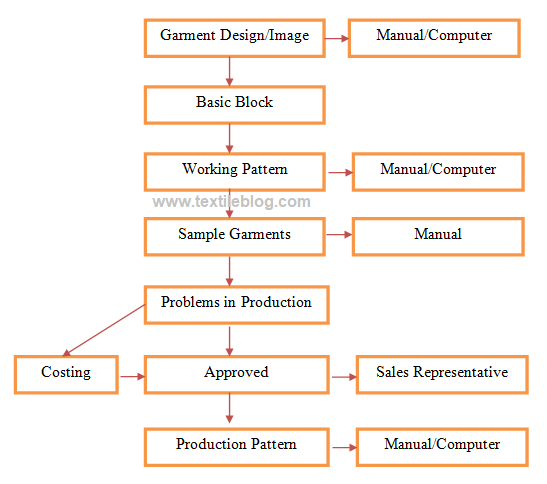

All technical and fabrication data are required to do the job properly. All technical and fabrication data are required to do the job properly. Working Flow Chart of Blow Room in Cotton Spinning. Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process. Fiber means any substance that have high length to width ratio.

Source: textilecircle24.blogspot.com

Source: textilecircle24.blogspot.com

Few cotton mills generally conduct the textile manufacturing process by generating fibers from cotton bales supplied and processing it ahead to attain fabrics. The production capacity of this spinning factory will be depends on our requirement. January 4 2021 by Mazharul Islam Kiron. But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. Process Flow Chart of Denim Manufacturing.

Source: pinterest.com

Source: pinterest.com

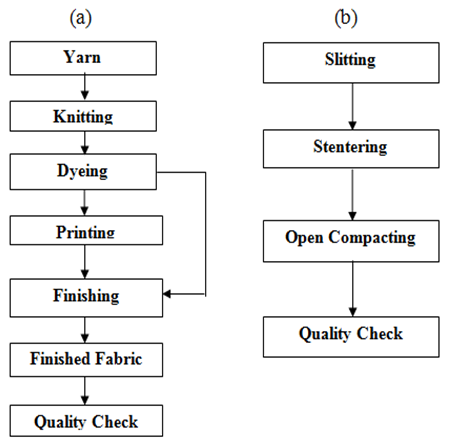

Wet Processing FlowChart Description-Stitching. It is typically used to make jeans overalls and other clothing. But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. Dyeing sequence for 100 cotton for light shade. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes.

Source: msrblog.com

Source: msrblog.com

In yarn dyeing floor. May 4 2013 at 512 am. Flow Chart for Raw Jute Production 7. Denim is a durable cotton twill textile in which the weft passes under two or more warp threads. This sequence is applicable for producing light shade less than 1.

![]() Source: textileblog.com

Source: textileblog.com

A special rubber formulation has to be made in order to apply this print to elastic material Flow chart of rubber printing process on cotton fabric 7. Process Flow Chart of Denim Manufacturing. Flow chart of jute yarn manufacturing process. Working Flow Chart of Blow Room in Cotton Spinning. Above weaving flow chart is mostly used for cotton and jute fabric.

Source: article.sapub.org

Source: article.sapub.org

Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process. Jute Jute Fabric Jute tree 6. Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. 40 to 70 of trash is removed in this section.

Source: msrblog.com

Source: msrblog.com

Load the package in the carrier and feed in the vessel. Process Flow Chart of Denim Manufacturing. Now I will give typical flow chart of cotton yarn dyeing. The denim fabrics are woven with a coarse count high thread density and 3 1 twill weave. On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding.

Source: textileblog.com

Source: textileblog.com

-List of Top 10 Denim Mills in Bangladesh-Flow Chart of Denim Manufacturing Process-Flow Chart of Denim Washing Process-Difference Between Denim and Jeans-Types of Denim Fabric Used in Garments Manufacturing-List of Top 100 Garment Buyers in Bangladesh-Top 50 Garments Buying Houses in Bangladesh-20 Woven Fabric Defects with Pictures. Cotton purchasing by import or from local market. It is a fabric made of cotton twill that is 100 cotton and very comfortable. Like flax and hemp it is a bast fiber being obtained from the stem of the jute plant. Above weaving flow chart is mostly used for cotton and jute fabric.

Source: textileinfomedia.com

Source: textileinfomedia.com

Flow Process chart of Jute Spinning 10. Tuft size of cotton becomes smaller in this section. Flow Chart for Raw Jute Production 7. The fabric is loaded in a machine fills with required water. Process for cotton yarn can be vary depending on the individual procedure of a textile engineer or a dyeing masterI have given a process flow chart for 100 cotton dyeing.

Flow Chart of Cotton Whitening Process. Carrier and vessel washed by hydrose and caustic at 100 0 C for 20 min. Flow Process chart of Jute Spinning 10. Flow Chart of Cotton Whitening Process. A special rubber formulation has to be made in order to apply this print to elastic material Flow chart of rubber printing process on cotton fabric 7.

Source: textileflowchart.com

Source: textileflowchart.com

April 30 2015 by textile-flowchart. If not then increase the time. It is the first step of spinning. The enzyme is added run for 30 minutes. Check the fabric if enzyme action is proper.

Source: pinterest.com

Source: pinterest.com

Fiber means any substance that have high length to width ratio. Like flax and hemp it is a bast fiber being obtained from the stem of the jute plant. Spinning process is an initial step to produce textile layout such as garments fabric home textile and so. January 4 2021 by Mazharul Islam Kiron. Flow chart of textile Processing Textile Fibers.

Source: article.sapub.org

Source: article.sapub.org

Flow chart of textile Processing Textile Fibers. Cost Analysis Dyeing Flow Chart For Acrylic Cotton. Cotton is a soft fluffy staple fiber. April 30 2015 by textile-flowchart. Although uses of jute has declined substantially over the last 30 years.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title how much process flow chart of cotton fabric in bangladesh by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.