Your Mercerization process of cotton fabric images are available. Mercerization process of cotton fabric are a topic that is being searched for and liked by netizens today. You can Get the Mercerization process of cotton fabric files here. Get all royalty-free photos and vectors.

If you’re looking for mercerization process of cotton fabric images information connected with to the mercerization process of cotton fabric keyword, you have pay a visit to the right site. Our site always provides you with suggestions for downloading the maximum quality video and picture content, please kindly search and locate more informative video articles and images that fit your interests.

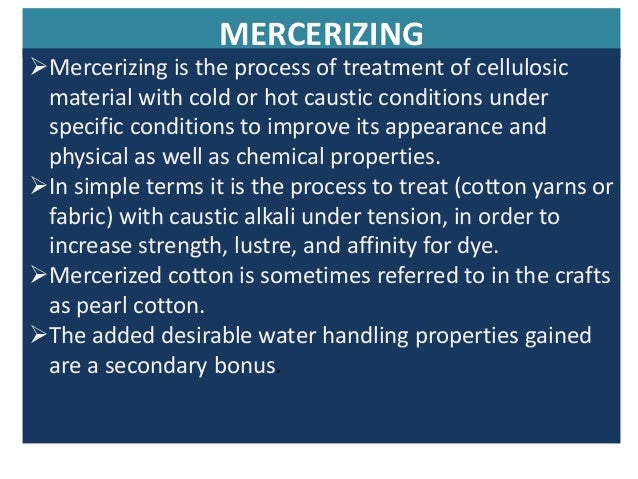

Mercerization Process Of Cotton Fabric. In dry mercerization the process is carried out while drying the fabric on a stenter. Mercerizing of cotton is done in three basic stages of materials. John Mercer invented a process which gives cotton a lustre resembling silk - a process known as mercerization. Process flow chart for cotton mercerizing of denim is given below.

Mercerization Textile Trick From textiletrick.com

Mercerization Textile Trick From textiletrick.com

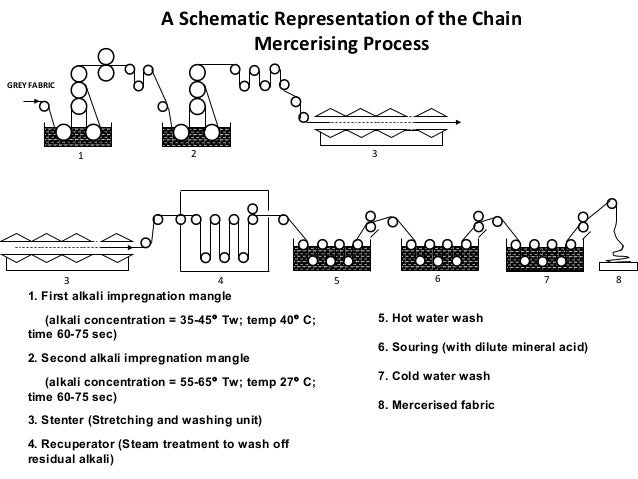

Anyhow following task is done one by one in different stages of the machine part. Mercerization is used for both pretreatment process and finishing process of fabric. This mercerization process with a low alkaline concentration mainly aims to improve dyestuff absorption in cotton and to produce a supplementary effect of scouring and with little alteration in the fabric dimensions and improvement in luster being expected it only requires a simple device effective in the production of casual wear that takes. Bleaching is enough for prepared the fabrics for dyeing and printing but mercerizing is done for adding some advantage to the fabric. A kier is normally attached so a solution of sodium hydroxide can be boiled under pressure by excluding oxygen which reduces the cellulose of the fiber. Steps of fabric processing in mercerization machine.

Woven and knit cotton fabrics with improved strength smooth drying appearance dimensional stability abrasion resistance and hand have been produced by rapid and continuous tension mercerization with liquid ammonia using an improved chainless mercerizer.

Cotton mercerizing is the most popular operation. Effective mercerization requires the use of wetting agents. A kier is normally attached so a solution of sodium hydroxide can be boiled under pressure by excluding oxygen which reduces the cellulose of the fiber. Mercerisation is an industrial process involving sodium hydroxide for cotton yarns or fabrics to increase the lustre and dyeability. Therefore it is mostly considered to be a finishing process rather than a preparatory process which is mainly carried out to facilitate. Bleaching is enough for prepared the fabrics for dyeing and printing but mercerizing is done for adding some advantage to the fabric.

Mercerization is a process in which textiles typical-ly cotton are treated with a caustic NaOH solution to improve properties such as fiber strength shrink-age resistance luster and dye affinity. The technology specifically comprises the following steps of inverse sewing singeing open-width refining and bleaching wet cropping wet cloth feeding alkali diluting high pressure mangling alkali rolling cloth drum tensioning high pressure mangling alkali rolling cloth drum. Mercerization is a process that makes cotton take dye better and increases its luster. Mercerizing of cotton is done in three basic stages of materials. Effective mercerization requires the use of wetting agents.

Source: coursehero.com

Source: coursehero.com

Mercerization is used for both pretreatment process and finishing process of fabric. Mercerization is a process for increasing absorbency strength and lustier of the fabric by physio-chemical treatment. Mercerization is a process applied to cotton yarns or fabrics which gives to the cotton fiber a silk-like luster a somewhat greater strength than that of ordinary cotton and a. This lead to a shrinkage of the treated fabrics with an increase in tensile strength and a better affinity for dyes. It was originally developed and patented by a man named John Mercer in 1844.

Source: article.sapub.org

Source: article.sapub.org

This video is all about mercerization process of cotton fabric. In dry mercerization the process is carried out while drying the fabric on a stenter. Mercerization is used for both pretreatment process and finishing process of fabric. The technology specifically comprises the following steps of inverse sewing singeing open-width refining and bleaching wet cropping wet cloth feeding alkali diluting high pressure mangling alkali rolling cloth drum tensioning high pressure mangling alkali rolling cloth drum. Mercerization Presented by Fatema Sharmin Department of wet processing engineering Bangladesh University of Textiles.

Source: advancetextile86.blogspot.com

Source: advancetextile86.blogspot.com

Mercerizing is done after bleaching operation. On the other hand it is known that the treatment brings about a. This mercerization process with a low alkaline concentration mainly aims to improve dyestuff absorption in cotton and to produce a supplementary effect of scouring and with little alteration in the fabric dimensions and improvement in luster being expected it only requires a simple device effective in the production of casual wear that takes. This video is all about mercerization process of cotton fabric. Therefore it is mostly considered to be a finishing process rather than a preparatory process which is mainly carried out to facilitate.

Source: researchgate.net

Source: researchgate.net

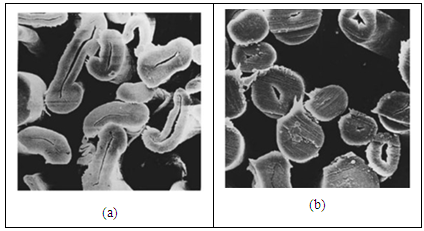

1011 and frictional propertiesThis process entails the treatment of cotton fabrics with sodium hydroxide 2025 concentration at 05C under tension. Luster and strength of the fabric increases for mercerizing process. Mercerization Mercerization in textiles a chemical treatment applied to cotton fibres or fabrics to permanently impart a greater affinity for dyes and various chemical finishes. In this investigation a selection of three common yarn patterns 295 984 and 38 was subjected to different mercerization experiments under factory conditions to optimize the caustic soda. Mercerization is one of the most common wet processing of cotton materials to improve the dyeing property.

Source: textiletoday.com.bd

Source: textiletoday.com.bd

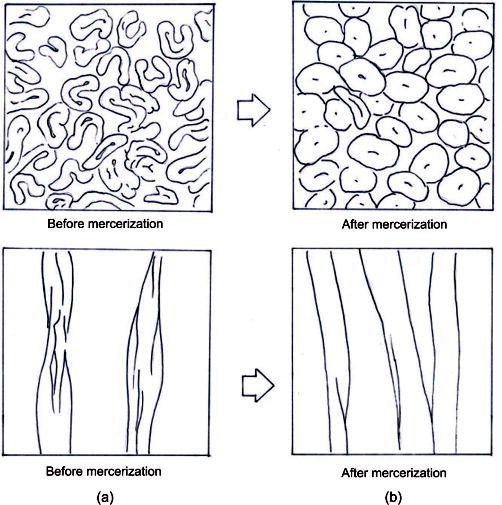

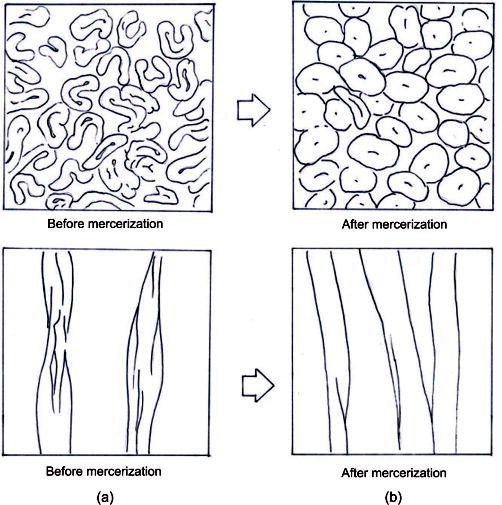

Mercerizing of cotton is done in three basic stages of materials. The mercerization treatment applied industrially to cotton fabrics to improve dye uptake absorbability stretchiness and strength is usually accompanied by an increase in fabric shrinkage see Fig. Luster and strength of the fabric increases for mercerizing process. Process flow chart for cotton mercerizing of denim is given below. Mercerization is a process applied to cotton yarns or fabrics which gives to the cotton fiber a silk-like luster a somewhat greater strength than that of ordinary cotton and a.

Source: youtube.com

Source: youtube.com

A kier is normally attached so a solution of sodium hydroxide can be boiled under pressure by excluding oxygen which reduces the cellulose of the fiber. The process is done sequencely. Mercerizing is a pre-treatment or finishing. Caustic soda mercerization of cotton is carried out for improvement of luster and dye uptake. The first steps is washing then mercerization is done in same machine.

Source: slideshare.net

Source: slideshare.net

Mercerizing of cotton is done in three basic stages of materials. Mercerisation is an industrial process involving sodium hydroxide for cotton yarns or fabrics to increase the lustre and dyeability. This mercerization process with a low alkaline concentration mainly aims to improve dyestuff absorption in cotton and to produce a supplementary effect of scouring and with little alteration in the fabric dimensions and improvement in luster being expected it only requires a simple device effective in the production of casual wear that takes. And this chemical treatment is occurred in two IMP-1 and IMP-2 bath by. Caustic soda mercerization of cotton is carried out for improvement of luster and dye uptake.

Source: researchgate.net

Source: researchgate.net

But the mercerisation of denim is usually carried out after the denim is woven and so it is different from the more common method of mercerising cotton yarn. Woven and knit cotton fabrics with improved strength smooth drying appearance dimensional stability abrasion resistance and hand have been produced by rapid and continuous tension mercerization with liquid ammonia using an improved chainless mercerizer. Caustic soda mercerization of cotton is carried out for improvement of luster and dye uptake. A kier is normally attached so a solution of sodium hydroxide can be boiled under pressure by excluding oxygen which reduces the cellulose of the fiber. Mercerization is a process that makes cotton take dye better and increases its luster.

Source: dharmatrading.com

Source: dharmatrading.com

On the other hand it is known that the treatment brings about a. Mercerizing is done after bleaching operation. On the other hand it is known that the treatment brings about a. Bleaching is enough for prepared the fabrics for dyeing and printing but mercerizing is done for adding some advantage to the fabric. However the process is a lso carried out sometimes to enhance dye ability to remove crease mark and remove naps from the fabric.

Source: textiletoday.com.bd

Source: textiletoday.com.bd

Bleaching is enough for prepared the fabrics for dyeing and printing but mercerizing is done for adding some advantage to the fabric. Commercial applications of mercerization are carried out to enhance the value of the finished fabric for the consumer. And this chemical treatment is occurred in two IMP-1 and IMP-2 bath by. Mercerization is one of the most common wet processing of cotton materials to improve the dyeing property. Woven and knit cotton fabrics with improved strength smooth drying appearance dimensional stability abrasion resistance and hand have been produced by rapid and continuous tension mercerization with liquid ammonia using an improved chainless mercerizer.

Source: advancetextile86.blogspot.com

Source: advancetextile86.blogspot.com

A kier is normally attached so a solution of sodium hydroxide can be boiled under pressure by excluding oxygen which reduces the cellulose of the fiber. Steps of fabric processing in mercerization machine. The fabric is boiled in an alkali which makes soap with free fatty acids. The treatment consists of immersing the yarn or fibre. The original process treated cotton with solutions of 5565 Twaddell scale 2030 sodium hydroxide followed by washing without any tension being applied to the fabric.

Source: academia.edu

Source: academia.edu

This video is all about mercerization process of cotton fabric. However the process is a lso carried out sometimes to enhance dye ability to remove crease mark and remove naps from the fabric. Effective mercerization requires the use of wetting agents. Mercerization is a process that makes cotton take dye better and increases its luster. John Mercer 1791-1866 5.

Source: pt.slideshare.net

Source: pt.slideshare.net

A kier is normally attached so a solution of sodium hydroxide can be boiled under pressure by excluding oxygen which reduces the cellulose of the fiber. On the other hand it is known that the treatment brings about a. But the mercerisation of denim is usually carried out after the denim is woven and so it is different from the more common method of mercerising cotton yarn. Process flow chart for cotton mercerizing of denim is given below. Luster and strength of the fabric increases for mercerizing process.

Source: bsamply.com

Source: bsamply.com

Woven and knit cotton fabrics with improved strength smooth drying appearance dimensional stability abrasion resistance and hand have been produced by rapid and continuous tension mercerization with liquid ammonia using an improved chainless mercerizer. This mercerization process with a low alkaline concentration mainly aims to improve dyestuff absorption in cotton and to produce a supplementary effect of scouring and with little alteration in the fabric dimensions and improvement in luster being expected it only requires a simple device effective in the production of casual wear that takes. Therefore it is mostly considered to be a finishing process rather than a preparatory process which is mainly carried out to facilitate. The technology specifically comprises the following steps of inverse sewing singeing open-width refining and bleaching wet cropping wet cloth feeding alkali diluting high pressure mangling alkali rolling cloth drum tensioning high pressure mangling alkali rolling cloth drum. The mercerization treatment applied industrially to cotton fabrics to improve dye uptake absorbability stretchiness and strength is usually accompanied by an increase in fabric shrinkage see Fig.

Source: youtube.com

Source: youtube.com

The process is done sequencely. However the process is a lso carried out sometimes to enhance dye ability to remove crease mark and remove naps from the fabric. Mercerization is one of the most common wet processing of cotton materials to improve the dyeing property. Commercial applications of mercerization are carried out to enhance the value of the finished fabric for the consumer. The original process treated cotton with solutions of 5565 Twaddell scale 2030 sodium hydroxide followed by washing without any tension being applied to the fabric.

Source: textiletrick.com

Source: textiletrick.com

Caustic soda mercerization of cotton is carried out for improvement of luster and dye uptake. On the other hand it is known that the treatment brings about a. The first steps is washing then mercerization is done in same machine. Mercerizing also gives cotton cloth increased tensile strength greater absorptive properties and usually a high degree of lustre depending on the method used. Mercerization in textiles a chemical treatment applied to cotton fibres or fabrics to permanently impart a greater affinity for dyes and various chemical finishes.

Source: researchgate.net

Source: researchgate.net

Mercerisation is an industrial process involving sodium hydroxide for cotton yarns or fabrics to increase the lustre and dyeability. Mercerizing is a pre-treatment or finishing. It was originally developed and patented by a man named John Mercer in 1844. However the process is a lso carried out sometimes to enhance dye ability to remove crease mark and remove naps from the fabric. 1011 and frictional propertiesThis process entails the treatment of cotton fabrics with sodium hydroxide 2025 concentration at 05C under tension.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title mercerization process of cotton fabric by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.