Your Process flow chart of cotton fabric crossword images are ready. Process flow chart of cotton fabric crossword are a topic that is being searched for and liked by netizens today. You can Get the Process flow chart of cotton fabric crossword files here. Find and Download all royalty-free photos.

If you’re searching for process flow chart of cotton fabric crossword pictures information linked to the process flow chart of cotton fabric crossword interest, you have pay a visit to the right site. Our website frequently gives you suggestions for refferencing the maximum quality video and image content, please kindly hunt and find more informative video content and graphics that fit your interests.

Process Flow Chart Of Cotton Fabric Crossword. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Some extra steps are added for combed yarn manufacturing. In this process the fibers in the bale form will be loosened opened and cleaned. Flow Chart of Wet Processing Process Cotton Goods This is the most widely used wet processing flowchart in the contemporary textile industry.

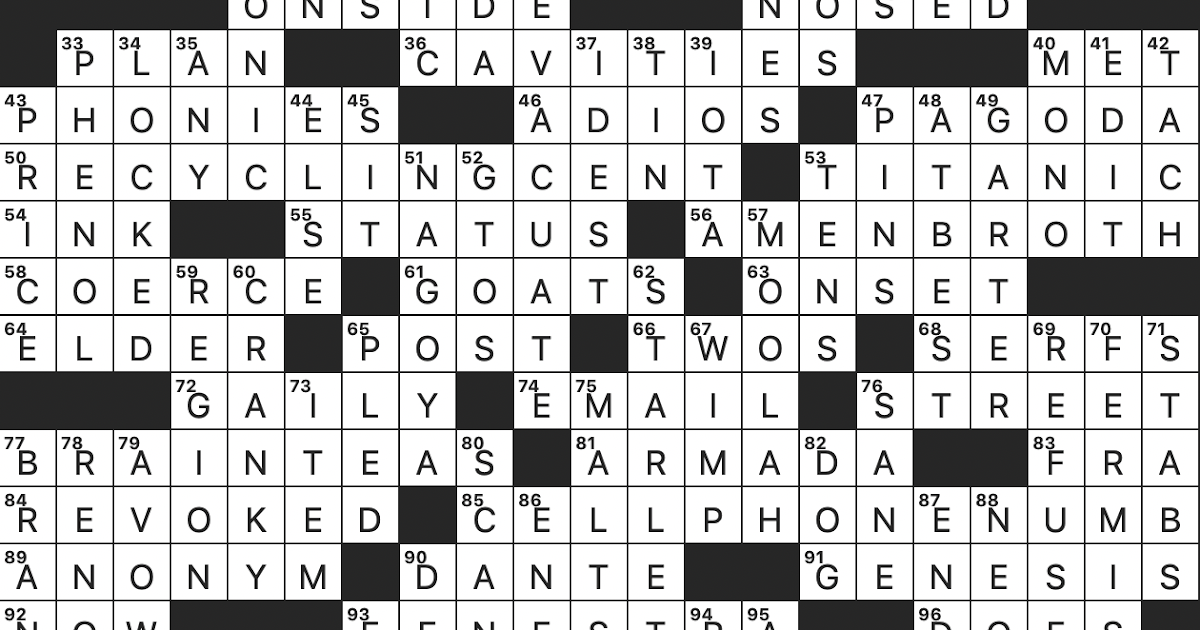

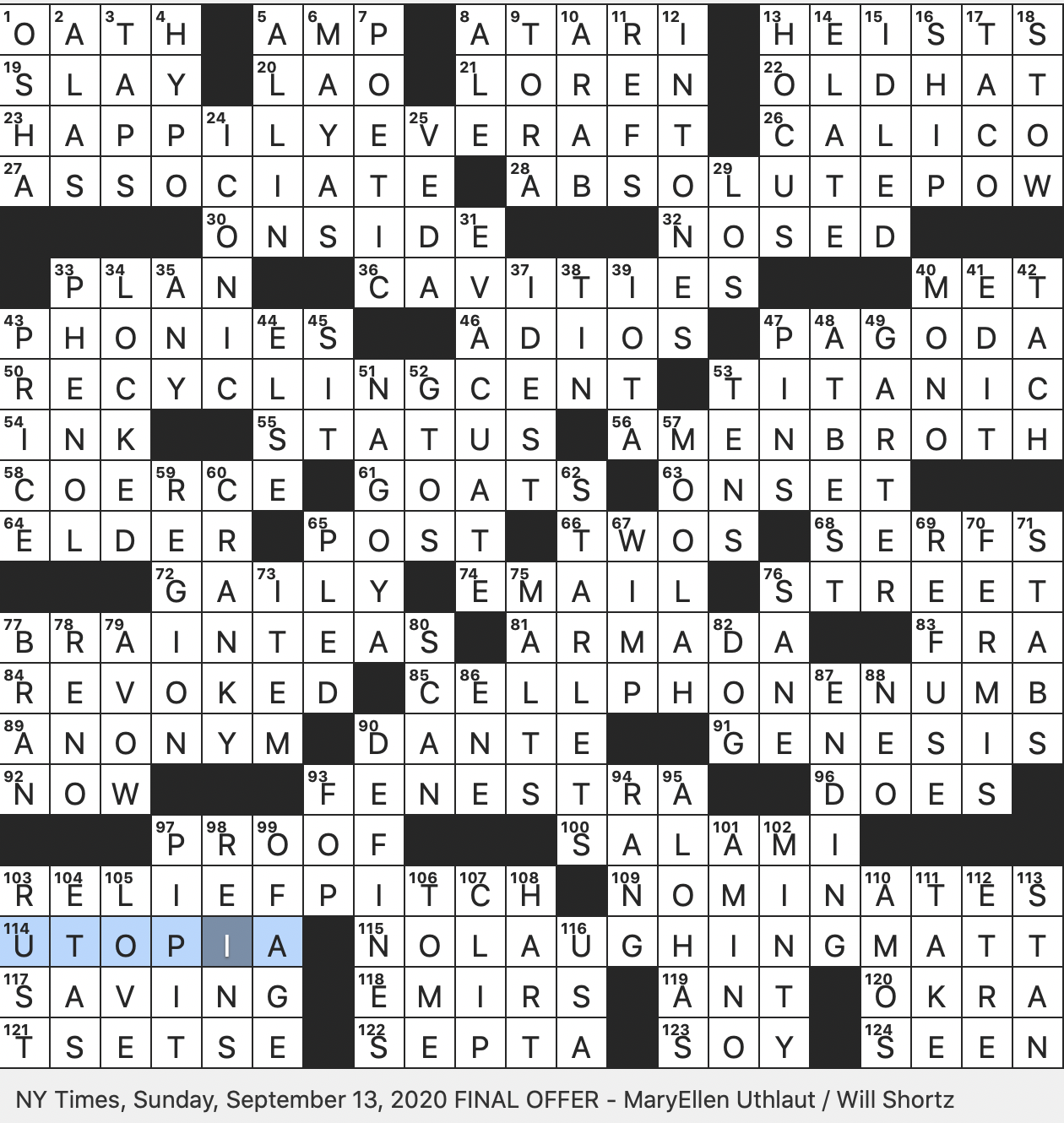

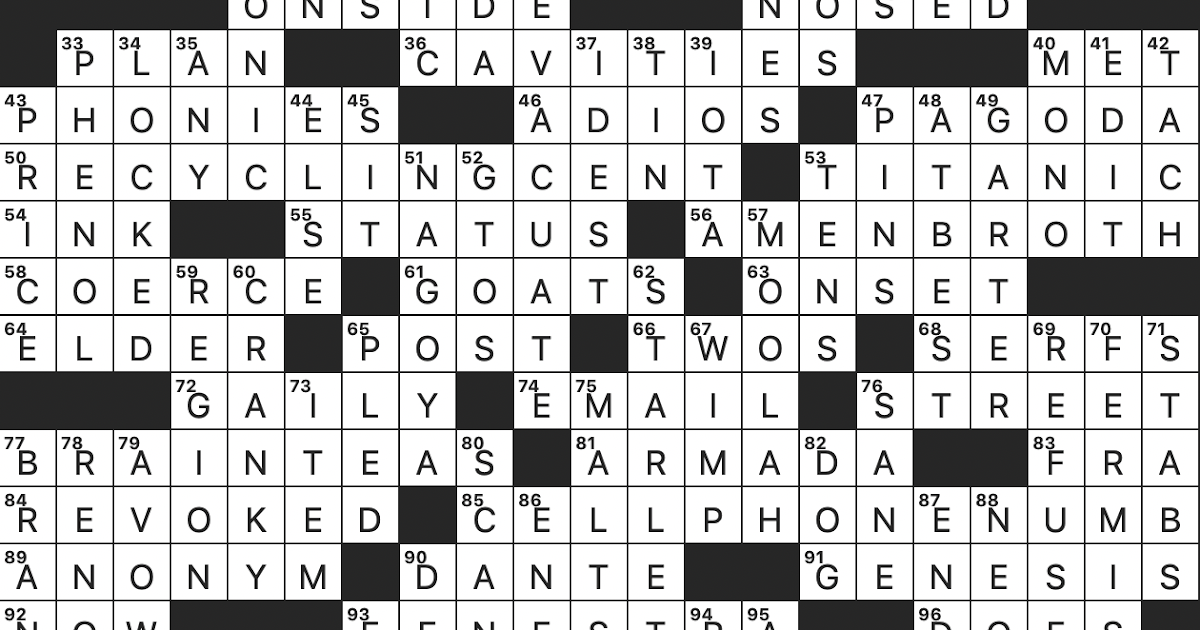

Rex Parker Does The Nyt Crossword Puzzle Small Anatomical Opening As In Bone Sun 9 13 20 Ground Dwelling Songbird Stark Who Was Crowned King In Game Of Thrones Finale Japanese From rexwordpuzzle.blogspot.com

Rex Parker Does The Nyt Crossword Puzzle Small Anatomical Opening As In Bone Sun 9 13 20 Ground Dwelling Songbird Stark Who Was Crowned King In Game Of Thrones Finale Japanese From rexwordpuzzle.blogspot.com

Wet processing is a two single word but means. The main aim of wet processing is take a gray cloth and make them finished fabric as it can make garments by take them into too many wet processing technique. Mercerizing neutralizing and washing is done between washing and stentering process. Flow Chart of Cotton Bleaching Process. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Blow room is the starting section of a cotton yarn spinning mill.

This is also necessary if discoloration or stains have occurred during the previous manufacturing process.

To be noted that a process flow chart made for the garment manufacturing processes will vary based on manufacturing facility and product types. Higher count yarn is produced by this process. Textile Manufacturing is a science and followed by a strict process. Wet processing process makes a fabric more useable more fineness and more attractive to the consumer. Cotton is a soft fluffy staple fiber. Quality Assurance Flow Chart of the Apparel Industry.

The amount of trash varies from 1 to 15 depending on the quality of the fibres. Higher count yarn is produced by this process. Combing is done after carding. But sometimes on some factories the scouring and bleaching are done simultaneously. Some extra steps are added for combed yarn manufacturing.

At first spinning process is begun with converting highly compressed cotton in bales into the form of a thoroughly loosened opened and cleaned state. Such as scouring bleaching dyeing hydro extractor or dewatering stitching stentering compacting softener padding relax drying final inspection. Knit fabric dyeing flow chart. Yarn Path Diagram of V-bed Flat MC. Textile Manufacturing is a science and followed by a strict process.

Source: wordmint.com

Source: wordmint.com

After carding the process is continued by drawing which includes attenuating in spinning mills. Flow Chart of Wet Processing Process Cotton Goods This is the most widely used wet processing flowchart in the contemporary textile industry. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Then this Ring is converting into winding cone by ring bobbin. Wet processing process makes a fabric more useable more fineness and more attractive to the consumer.

But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. It is a natural and most popular fiber. Knit fabric dyeing flow chart are discussing below. At first we should collect yarn from spinning which is made by following a process such as blow room carding pre-comber drawing super lap former combing drawing simplex ring frame. In this process the fibers in the bale form will be loosened opened and cleaned.

Source: pinterest.com

Source: pinterest.com

The silver produced. The main aim of wet processing is take a gray cloth and make them finished fabric as it can make garments by take them into too many wet processing technique. Knit Fabric Manufacturing Process with Flow Chart. Above weaving flow chart is mostly used for cotton and jute fabric. Wet processing process makes a fabric more useable more fineness and more attractive to the consumer.

Source: pinterest.com

Source: pinterest.com

Wet processing is a two single word but means. Each process of textile manufacturing is maintained with pre-defined sequences and the textile engineers usually follow the flow chart step by step to produce the better textile products that have been ordered by buyer. Then this Ring is converting into winding cone by ring bobbin. Process flow chart of weaving technology is given below. Discuss on Textile Manufacturing Process.

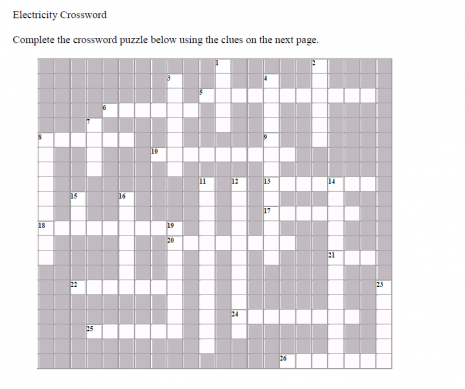

Source: studylib.net

Source: studylib.net

See more ideas about flow chart process flow chart process flow. Some extra steps are added for combed yarn manufacturing. If the cloth is to be finished white or is to be given surface ornamentation all-natural color must be removed by bleaching. Wet processing is a two single word but means. The silver produced.

At first spinning process is begun with converting highly compressed cotton in bales into the form of a thoroughly loosened opened and cleaned state. Knit fabric dyeing flow chart are discussing below. Feb 17 2017 - Explore room203 textiless board FlowCharts TextiLes dT on Pinterest. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Production Flow Chart of Wet Processing for Woven Fabric 21.

Flow Chart is a branch of data where the operation list shows sequence wise to understand what the process will set after a process. Flow Chart is a branch of data where the operation list shows sequence wise to understand what the process will set after a process. On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. Combing is done for adding extra features to the fibers. This is also necessary if discoloration or stains have occurred during the previous manufacturing process.

Source: wordmint.com

Source: wordmint.com

Higher count yarn is produced by this process. It is noted that above flow chart is for non mercerized fabric. On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. To be noted that a process flow chart made for the garment manufacturing processes will vary based on manufacturing facility and product types. Some extra steps are added for combed yarn manufacturing.

Source: pinterest.com

Source: pinterest.com

Flow chart of synthetic process of man-made fiber. These processes are carried out to impart a particular property related to that. Wet processing process makes a fabric more useable more fineness and more attractive to the consumer. Generally we make two kinds of garment products in the apparel industry one is the top item another is the bottom item. Cotton is a soft fluffy staple fiber.

Source: assist.asta.edu.au

Source: assist.asta.edu.au

Fabric comes from knitting. The flow chart of cotton dyeing process of cotton is given below. In this process the fibers in the bale form will be loosened opened and cleaned. Some extra steps are added for combed yarn manufacturing. Knit fabric dyeing flow chart.

Source: rexwordpuzzle.blogspot.com

Source: rexwordpuzzle.blogspot.com

April 30 2015 by textile-flowchart. Flow Chart of Cotton Bleaching Process. See more ideas about flow chart process flow chart process flow. The main aim of wet processing is take a gray cloth and make them finished fabric as it can make garments by take them into too many wet processing technique. Normally imported cotton fibrs are in bale form which are highly compact form.

Source: rexwordpuzzle.blogspot.com

Source: rexwordpuzzle.blogspot.com

Wet processing process makes a fabric more useable more fineness and more attractive to the consumer. Generally we make two kinds of garment products in the apparel industry one is the top item another is the bottom item. Then this Ring is converting into winding cone by ring bobbin. Blow room is the starting section of a cotton yarn spinning mill. But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric.

Combed yarn is finer than carded or rotor yarn. Some extra steps are added for combed yarn manufacturing. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Process Flow Chart of Knit Dyeing. This is also necessary if discoloration or stains have occurred during the previous manufacturing process.

Source: wordmint.com

Source: wordmint.com

The silver produced. Cotton is a soft fluffy staple fiber. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. See more ideas about flow chart process flow chart process flow. Then this Ring is converting into winding cone by ring bobbin.

Spinning is a procedure of producingconverting fiber materials in yarns. Flow chart of synthetic process of man-made fiber. Knit fabric dyeing flow chart. Wet processing is a two single word but means. Textile Manufacturing is a science and followed by a strict process.

Source: pinterest.com

Source: pinterest.com

Spinning is a procedure of producingconverting fiber materials in yarns. The trash materials are broken seeds husks broken leaf dirts and short fibres etc. Feb 17 2017 - Explore room203 textiless board FlowCharts TextiLes dT on Pinterest. Above weaving flow chart is mostly used for cotton and jute fabric. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title process flow chart of cotton fabric crossword by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.