Your Process flow chart of cotton fabric job images are ready in this website. Process flow chart of cotton fabric job are a topic that is being searched for and liked by netizens today. You can Get the Process flow chart of cotton fabric job files here. Find and Download all free images.

If you’re searching for process flow chart of cotton fabric job images information related to the process flow chart of cotton fabric job keyword, you have visit the right site. Our website frequently gives you suggestions for viewing the maximum quality video and picture content, please kindly hunt and find more enlightening video articles and graphics that match your interests.

Process Flow Chart Of Cotton Fabric Job. In this article I will give manufacturing process flow chart of terry towel. Brief of weaving process. If not then increase the time. 2 Download Print 100 Free.

Sample Flow Chart Npuc Needlepunched Fabric Made With Ultraclean O Download Scientific Diagram From researchgate.net

Sample Flow Chart Npuc Needlepunched Fabric Made With Ultraclean O Download Scientific Diagram From researchgate.net

Check the pH 34-48 of liquor. The amount of trash varies from 1 to 15 depending on the quality of the fibres. Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. It is a natural and most popular fiber. The person who do this job is called merchandiser. Wet processing flow chart for cotton.

Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc.

The enzyme is added run for 30 minutes. Since the sales process often starts with the eyes merchandising typically involves presenting products in a visually. Fabric dyeing - Google Search. Commercial embroidery is a new business introduced in Pakistan a few years ago. Cotton printing is the most used process. Check the pH 34-48 of liquor.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

Above weaving flow chart is mostly used for cotton and jute fabric. Fabric Receiving Fabric Relaxation. Process flow chart of cutting section is as follows. Commercial embroidery is a new business introduced in Pakistan a few years ago. This is also necessary if discoloration or stains have occurred during the previous manufacturing process.

Source: practicaltextile.com

Source: practicaltextile.com

Dyeing Process Knit dyeing is a technique of dyeing the knitted fabrics. Brief of weaving process. Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. 1 See Flowchart Templates Customize. Wet processing flow chart for cotton.

Source: researchgate.net

Source: researchgate.net

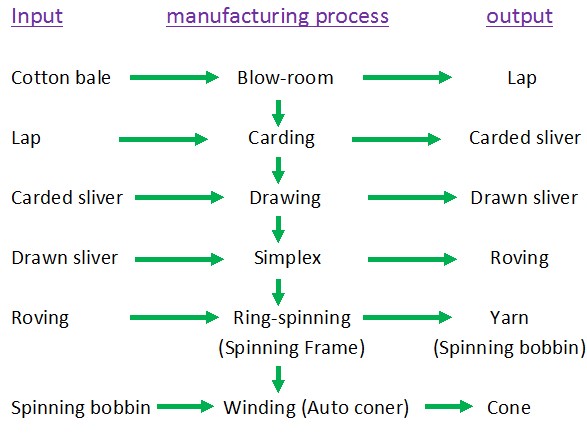

Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Fabric consider as a major raw material in the garments manufacturing process. In mass production multiple layers of fabrics are laid on a table and large number of apparels is being cut at a time. The original way of wet processing is most important. Blow room is the starting section of a cotton yarn spinning mill.

Source: researchgate.net

Source: researchgate.net

A process flow chart helps to understand how raw materials are moved from one process to another process until raw materials are transformed into the desired product garments. If the cloth is to be finished white or is to be given surface ornamentation all-natural color must be removed by bleaching. The laid fabric stack is called as lay. Flow Chart of Cotton Bleaching Process. Fabric dyeing - Google Search.

Source: ordnur.com

Source: ordnur.com

1 See Flowchart Templates Customize. Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process. Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Ad 1 Create A Flow Chart With Our Easy Online Tool.

Source: researchgate.net

Source: researchgate.net

Process Flow Of Printing Process For 100 Cotton Fabric. Normally imported cotton fibrs are in bale form which are highly compact form. Ad 1 Create A Flow Chart With Our Easy Online Tool. Find this Pin and more on Dyeing by Tracey. The original way of wet processing is most important.

Source: pinterest.com

Source: pinterest.com

Process Flow Chart of Knit Dyeing. The flow chart of cotton dyeing process of cotton is given below. Process flow chart of cutting section is as follows. The printing flow chart depends on the fiber types. The amount of trash varies from 1 to 15 depending on the quality of the fibres.

Source: pinterest.com

Source: pinterest.com

Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. Make A Flow Chart To Show The Process Innvoled In Making Fabrics From Cotton Fibers Science Fibre Fabric 6921350 Meritnation. Natural fiber such as- cotton wool and silk contains various types of impurities for this reason it is required to remove the impurities before dyeing and printing process. Normally imported cotton fibrs are in bale form which are highly compact form. Fabric dyeing - Google Search.

Source: pinterest.com

Source: pinterest.com

Fabric Receiving Fabric Relaxation. Check the fabric if enzyme action is proper. Such as scouring bleaching dyeing hydro extractor or dewatering stitching stentering compacting softener padding relax drying final inspection. 2 Download And Print Now - 100 Free. A process flow chart helps to understand how raw materials are moved from one process to another process until raw materials are transformed into the desired product garments.

Source: pinterest.com

Source: pinterest.com

Process flow chart of weaving technology is given below. Fabric dyeing - Google Search. It is a natural and most popular fiber. Flow of the weaving process. Dyeing Process Knit dyeing is a technique of dyeing the knitted fabrics.

Source: brainly.in

Source: brainly.in

Wet processing process makes a fabric more useable more fineness and more attractive to the consumer. This is ideal follow chart for cotton dyeing which is help somebody to know about cotton fabric or yarn dying. These processes are carried out to impart a particular property related to that. Process flow chart of weaving technology is given below. Wet processing process makes a fabric more useable more fineness and more attractive to the consumer.

Source: researchgate.net

Source: researchgate.net

Wet processing process makes a fabric more useable more fineness and more attractive to the consumer. Follow chart is part and parcel in textile industry. Normally imported cotton fibrs are in bale form which are highly compact form. The enzyme is added run for 30 minutes. Such as scouring bleaching dyeing hydro extractor or dewatering stitching stentering compacting softener padding relax drying final inspection.

Source: researchgate.net

Source: researchgate.net

Flow Chart of Cotton Whitening Process. Since the sales process often starts with the eyes merchandising typically involves presenting products in a visually. The person who do this job is called merchandiser. The main aim of wet processing is take a gray cloth and make them finished fabric as it can make garments by take them into too many wet processing technique. See more ideas about process flow chart process flow flow chart.

Source: in.pinterest.com

Source: in.pinterest.com

Natural fiber such as- cotton wool and silk contains various types of impurities for this reason it is required to remove the impurities before dyeing and printing process. Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process. The flow chart of cotton dyeing process of cotton is given below. The fabric consists of one series of weft thread and. Flow Chart of Cotton Whitening Process.

Source: researchgate.net

Source: researchgate.net

The original way of wet processing is most important. Process Flow Chart of Knit Dyeing. Above weaving flow chart is mostly used for cotton and jute fabric. The fabric consists of one series of weft thread and. Find this Pin and more on Dyeing by Tracey.

Source: textileinfomedia.com

Source: textileinfomedia.com

This is ideal follow chart for cotton dyeing which is help somebody to know about cotton fabric or yarn dying. Commercial embroidery is a new business introduced in Pakistan a few years ago. If the cloth is to be finished white or is to be given surface ornamentation all-natural color must be removed by bleaching. The enzyme is added run for 30 minutes. The fabric is loaded in a machine fills with required water.

Source: ordnur.com

Source: ordnur.com

Wet processing process makes a fabric more useable more fineness and more attractive to the consumer. The main aim of wet processing is take a gray cloth and make them finished fabric as it can make garments by take them into too many wet processing technique. The enzyme is added run for 30 minutes. Knitted fabrics undergo a series of different chemical processing treatments. The garment manufacturing process involved a number of processes from order receiving to dispatching shipment of the finished garments.

Source: ordnur.com

Source: ordnur.com

Process Flow Chart of Knit Dyeing. Flow Chart of Cotton Whitening Process. This is ideal follow chart for cotton dyeing which is help somebody to know about cotton fabric or yarn dying. 1 See Flowchart Templates Customize. Check the fabric if enzyme action is proper.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title process flow chart of cotton fabric job by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.