Your Process flow chart of cotton fabric ltd images are ready. Process flow chart of cotton fabric ltd are a topic that is being searched for and liked by netizens now. You can Find and Download the Process flow chart of cotton fabric ltd files here. Download all royalty-free vectors.

If you’re looking for process flow chart of cotton fabric ltd pictures information related to the process flow chart of cotton fabric ltd keyword, you have come to the right blog. Our site frequently gives you suggestions for seeking the highest quality video and image content, please kindly surf and find more informative video content and images that fit your interests.

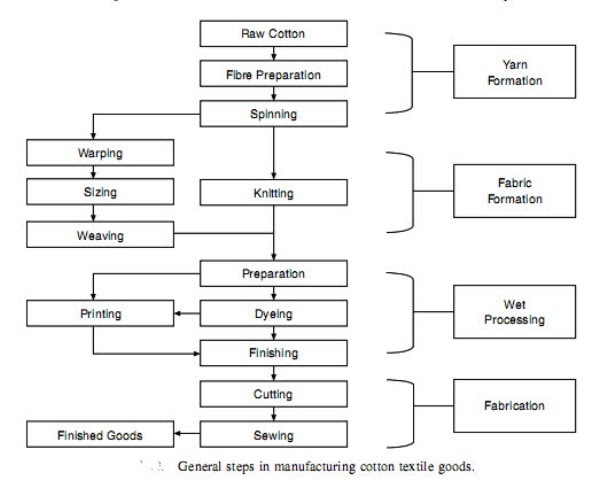

Process Flow Chart Of Cotton Fabric Ltd. ECMaduranga Ediriweera Reg No. Flowchart of the flow chart of 100 cotton fabric dyeing is given below. It is a natural and most popular fiber. There is a lot of potential in this business because of less number of factories in the market and an increasing demand of embroidery in local as well as international market.

Cotton Flow Chart Barnhardt Purified Cotton From barnhardtcotton.net

Cotton Flow Chart Barnhardt Purified Cotton From barnhardtcotton.net

The silver produced. Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. If not then increase the time. Flowchart of the flow chart of 100 cotton fabric dyeing is given below. Feb 4 2021 - Chart of Super White Wash is done on the garments made from cotton grey fabrics. The main purposes of super white wash are to make white.

Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes.

Rossari Biotech Ltd Mumbai India 1. Fabric consider as a major raw material in the garments manufacturing process. Feb 4 2021 - Chart of Super White Wash is done on the garments made from cotton grey fabrics. Weaving is done by the interlacement of these two types of yarn. After carding the process is continued by drawing which includes attenuating in spinning mills. Textile Manufacturing Processes For S And Professionals.

Source: researchgate.net

Source: researchgate.net

Vision Cotton Club BD Ltd will endeavor to attain a position of leadership in each category of its businesses. This mercerization process with a low alkaline concentration mainly aims to improve dyestuff absorption in cotton and to produce a supplementary effect of scouring and with little alteration in the fabric dimensions and improvement in luster being expected it only requires a simple device effective in the production of casual wear that takes. Textile Manufacturing Processes For S And Professionals. The fabric is loaded in a machine fills with required water. Now auxiliary chemicals acid are added.

Source: pinterest.com

Source: pinterest.com

Cotton is a soft fluffy staple fiber. Flow Chart of Warping Process is defined as the parallel winding of yarn from cone or cheese. The fabric is loaded in a machine fills with required water. Now auxiliary chemicals acid are added. Cotton is still the King of fibers because most of the worlds apparel is made of Cotton.

Source: pinterest.com

Source: pinterest.com

Spinning is a procedure of producingconverting fiber materials in yarns. Flow Chart of Warping Process is defined as the parallel winding of yarn from cone or cheese. 1 COTTON YARN MANUFACTURING PROCESS DIPLOMA IN TEXTILE APPEREL TECHNOLOGY SRI LANKA INSTITUTE OF TEXTILE APPAREL 20142015 Name. Flow chart of textile Processing Textile Fibers. Simple and sustainable reuse and recycle strategies were investigated with the intention of assessing ways to curb water consumption in the textile wet processing.

Source: barnhardtcotton.net

Source: barnhardtcotton.net

Now auxiliary chemicals acid are added. Printing is a method of wet processing technologyBy the printing process. Fiber means any substance that have high length to width ratio. Normally reactive dye is used for dyeing cotton fiber. 21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties.

Source: pinterest.com

Source: pinterest.com

Values Strong work force that ensures quality finished fabric. If not then increase the time. Apart from its fairly good strength it is considered to provide comfort due to good moisture absorption and wicking properties 1. Flow Chart of Fabric Dyeing. The polyester part is dyed first then the cotton part is dyed.

Source: toppr.com

Source: toppr.com

Weaving is done by the interlacement of these two types of yarn. A process flow chart helps to understand how raw materials are moved from one process to another process until raw materials are transformed into the desired product garments. Cotton can be died also with vat dye direct dye sulfur dye mordant dye etc. Flow Chart of Warping Process is defined as the parallel winding of yarn from cone or cheese. Above weaving flow chart is mostly used for cotton and jute fabric.

Source: nuchemdyestuffs.blogspot.com

Source: nuchemdyestuffs.blogspot.com

Check the pH 34-48 of liquor. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Flow Chart of Cotton Dyeing Process. Fiber means any substance that have high length to width ratio. Cotton is a natural fiber.

ECMaduranga Ediriweera Reg No. Now auxiliary chemicals acid are added. Cotton is a natural fiber. 21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties. In this dyeing process.

Source: researchgate.net

Source: researchgate.net

100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. Values Strong work force that ensures quality finished fabric. The flow chart of cotton dyeing process of cotton is given below. Typical preparation processes used for cotton and cotton blend yarns and fabrics. Flow Chart of PolyesterCotton Blended Fabric Dyeing is as follows.

Source: researchgate.net

Source: researchgate.net

Feb 4 2021 - Chart of Super White Wash is done on the garments made from cotton grey fabrics. Feb 4 2021 - Chart of Super White Wash is done on the garments made from cotton grey fabrics. To be noted that a process flow chart made for the garment manufacturing processes will vary based on manufacturing facility and product types. The silver produced. Each process requires a plethora of chemicals along with water out of which the unexhausted chemicals are drained in the.

Source: researchgate.net

Source: researchgate.net

Yarn Manufacturing Process Flow Chart A Prehensive Look. Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. Vision Cotton Club BD Ltd will endeavor to attain a position of leadership in each category of its businesses. Flow chart of textile Processing Textile Fibers. Above weaving flow chart is mostly used for cotton and jute fabric.

Source: meritnation.com

Source: meritnation.com

100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. Cotton is a soft fluffy staple fiber. Rossari Biotech Ltd Mumbai India 1. Cotton printing is the most used process. Typical preparation processes used for cotton and cotton blend yarns and fabrics.

Source: researchgate.net

Source: researchgate.net

Printing is a method of wet processing technologyBy the printing process. Each process requires a plethora of chemicals along with water out of which the unexhausted chemicals are drained in the. The fabric is loaded in a machine fills with required water. Flow Chart of Fabric Dyeing. Commercial embroidery is a new business introduced in Pakistan a few years ago.

Source: snapsolve.com

Source: snapsolve.com

But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. ECMaduranga Ediriweera Reg No. DTAT-P212014 Name Of Department. Introduction Cotton is the leading fibre in Textile Industry. Cotton is still the King of fibers because most of the worlds apparel is made of Cotton.

Source: researchgate.net

Source: researchgate.net

Flow Chart of Cotton Whitening Process. After carding the process is continued by drawing which includes attenuating in spinning mills. On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. Textile Manufacturing Processes For S And Professionals. Flow Chart of Fabric Dyeing.

Source: pinterest.com

Source: pinterest.com

Now auxiliary chemicals acid are added. In the case of polyestercotton blended fabric double dyeing is done. Process flow chart of weaving technology is given below. Various types of decorative and attractive designs are produced on the surface of the fabric. But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric.

Source: researchgate.net

Source: researchgate.net

April 30 2015 by textile-flowchart. Rossari Biotech Ltd Mumbai India 1. Cotton Yarn Manufacturing Process 1 1. Yarn Manufacturing Process Flow Chart A Prehensive Look. Eurotex Industries And Exports Ltd.

Source: ordnur.com

Source: ordnur.com

Check the pH 34-48 of liquor. The main purposes of super white wash are to make white. Process Flowchart For The Ion Of Knitted Fabrics And Wet Scientific Diagram. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. In this dyeing process.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title process flow chart of cotton fabric ltd by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.