Your Process flow chart of cotton fabric online images are ready. Process flow chart of cotton fabric online are a topic that is being searched for and liked by netizens now. You can Find and Download the Process flow chart of cotton fabric online files here. Find and Download all royalty-free photos and vectors.

If you’re searching for process flow chart of cotton fabric online images information related to the process flow chart of cotton fabric online interest, you have come to the ideal blog. Our site always gives you hints for refferencing the highest quality video and picture content, please kindly search and find more enlightening video content and images that match your interests.

Process Flow Chart Of Cotton Fabric Online. Table preparation Fabric plaited on the table Crack pasteclear apply with the help of screen Dry in air temp or hand dryer mc slight Printing paste apply with the help of screen Curing at 190ºc belt speed 2 mmin Delivery. The silver produced. Sep 19 2020 - Explore Textile Yarn Spinning Revolutis board cotton process flow chart on Pinterest. The knitted fabric produced by loop forming.

Sample Flow Chart Npuc Needlepunched Fabric Made With Ultraclean O Download Scientific Diagram From researchgate.net

Sample Flow Chart Npuc Needlepunched Fabric Made With Ultraclean O Download Scientific Diagram From researchgate.net

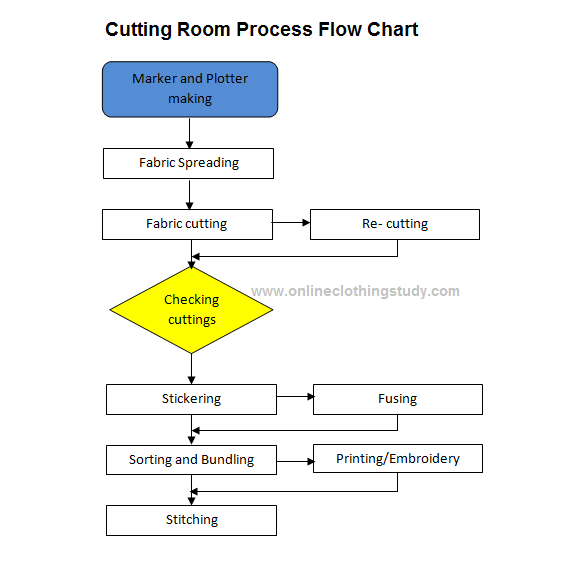

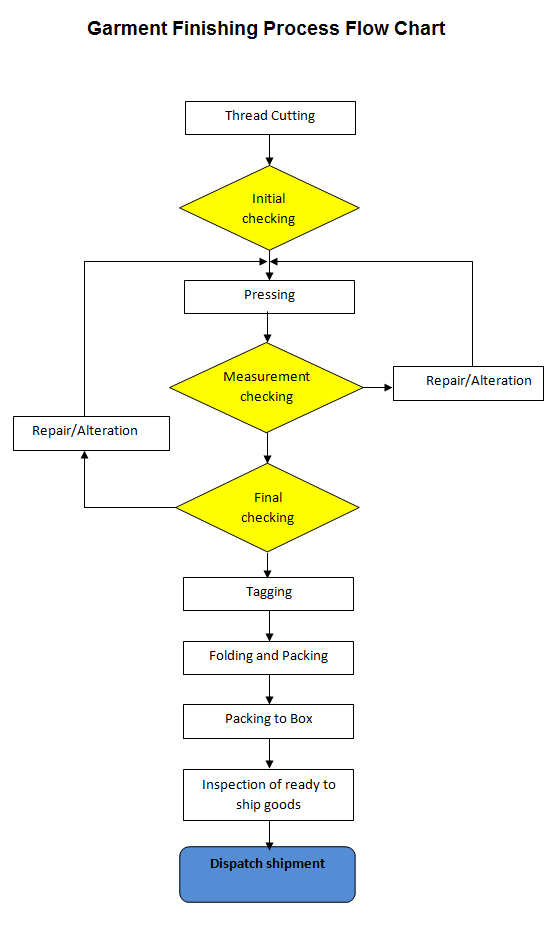

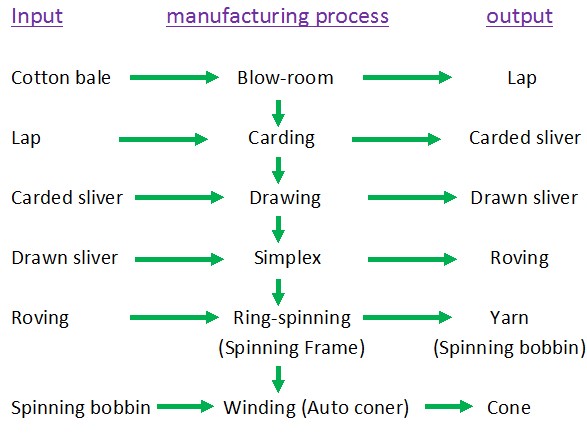

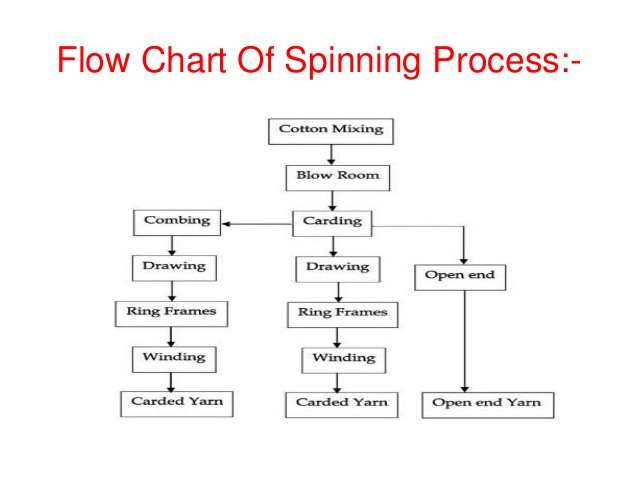

While you read the history of denim jeans It would be a good addition to knowing the denim fabric production processes and jeans manufacturing process. Yarn spinning is a process of making or converting fiber materials into yarnsIt is the primary Process of Textile Product. In this article I will explain all process separately. April 30 2015 by textile-flowchart. This process is known. Selection of fabric and trims as per the buyer specification.

On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding.

Process Flow Chart Of Crack Printing. Procurement of fabric trims and accessories. They follow these steps to manufacture trousers listed in the sequence of occurrence -. Cotton Spinning process flow chart. Flow Chart of Cotton Dyeing Process. 47 rows Wet processing flow chart for cotton.

Source: pinterest.com

Source: pinterest.com

Typical preparation processes used for cotton and cotton blend yarns and fabrics. April 30 2015 by textile-flowchart. Table preparation Fabric plaited on the table Crack pasteclear apply with the help of screen Dry in air temp or hand dryer mc slight Printing paste apply with the help of screen Curing at 190ºc belt speed 2 mmin Delivery. The denim manufacturing process is explained in the detail in this article. Flow chart of cotton carded ring spun yarn production along with input and.

Source: in.pinterest.com

Source: in.pinterest.com

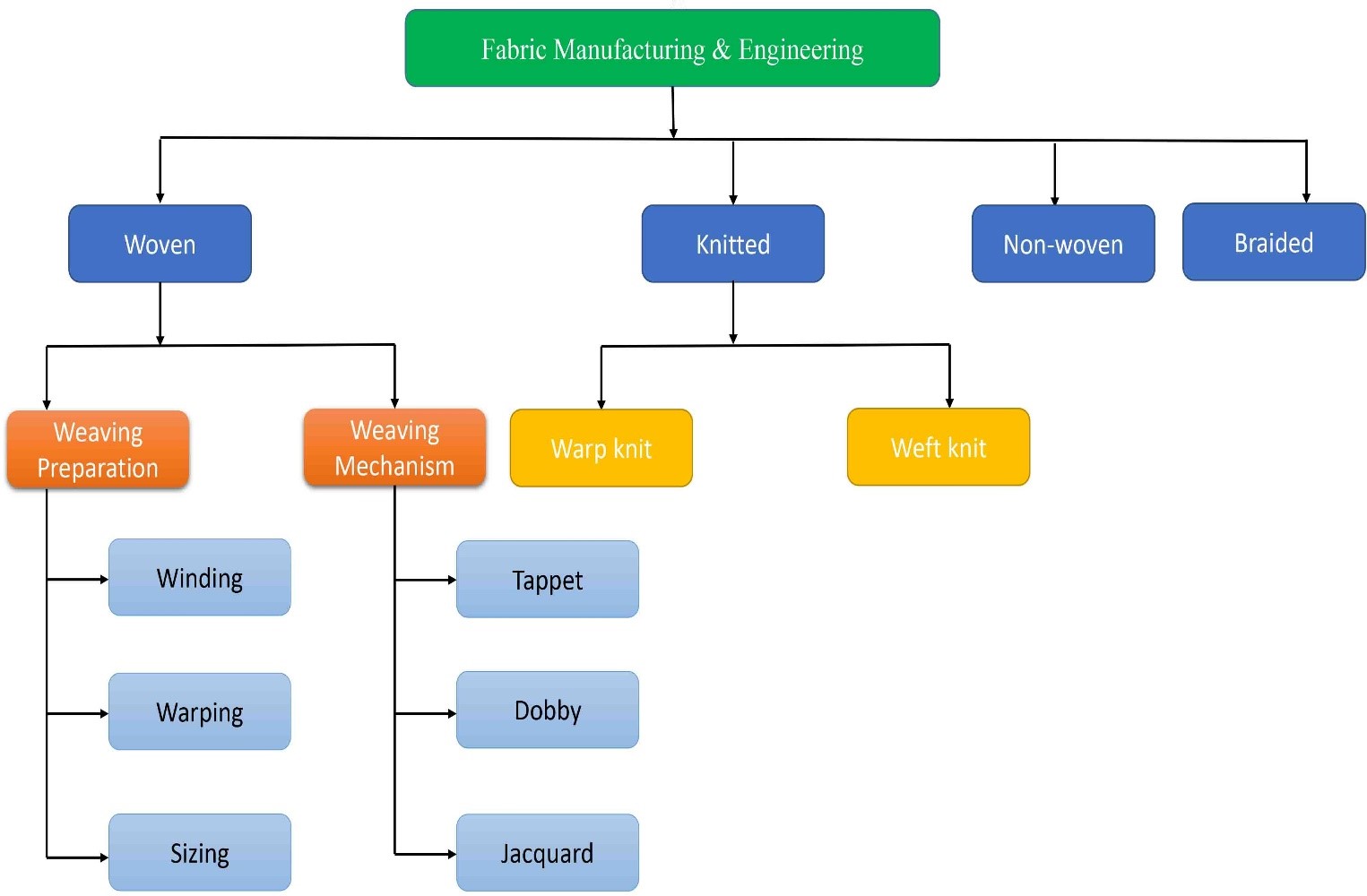

Process Flow Chart Of Crack Printing. 2 Download Print 100 Free. They are weaving knitting and non-weaving. It consists of different processes. The process of trouser manufacturing when done by a full-package manufacturer involved the following processes.

Source: researchgate.net

Source: researchgate.net

Process Flow Of Printing Process For 100 Cotton Fabric. Process Flow Chart of Denim Production. On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. Cotton is a natural fiber. Connecting Threads Shop Online Now.

Source: pinterest.com

Source: pinterest.com

Cotton is a soft fluffy staple fiber. Natural fiber such as- cotton wool and silk contains various types of impurities for this reason it is required to remove the impurities before dyeing and printing process. It is one of the most easily dyeable fibers. The main aim of wet processing is take a gray. Flow charts of cotton carded ring spun cotton combed ring spun open end rotor spun and air jet spun yarns with input and output materials are given in below respectively.

Source: researchgate.net

Source: researchgate.net

They follow these steps to manufacture trousers listed in the sequence of occurrence -. They are weaving knitting and non-weaving. Ad We Love Quilting As Much As You Do. April 30 2015 by textile-flowchart. The denim manufacturing process is explained in the detail in this article.

Source: researchgate.net

Source: researchgate.net

Blending apron has sharp spikes the raise cotton until part of it is knocked off. The denim manufacturing process is explained in the detail in this article. Process Flow Chart of Denim Production. 21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties. Following sequence is the crack printing.

Source: researchgate.net

Source: researchgate.net

Those garment have not got miracley but those have to pass many stages from textiles fiber example. Flow charts of cotton carded ring spun cotton combed ring spun open end rotor spun and air jet spun yarns with input and output materials are given in below respectively. Cotton is a soft fluffy staple fiber. In this article I will explain all process separately. During denim fabric manufacturing a process flow-chart should maintain to facilitate the fabric manufacturing process which is discussed in this article.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

Apron moves cotton to blending apron. Natural fiber such as- cotton wool and silk contains various types of impurities for this reason it is required to remove the impurities before dyeing and printing process. Process Flow Chart of Denim Production. 21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties. Normally denim is a twill weave is woven and 100 cotton fabric that contains dyed warp yarn and grey weft yarn.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. The printing flow chart depends on the fiber types. During denim fabric manufacturing a process flow-chart should maintain to facilitate the fabric manufacturing process which is discussed in this article. Yarn spinning is a process of making or converting fiber materials into yarnsIt is the primary Process of Textile Product. Cotton is passed from bales and then to apron.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

1 Create A Flowchart In 5 Minutes. Procurement of fabric trims and accessories. Fabric dyeing - Google Search. Cotton can be died also with vat dye direct dye sulfur dye mordant dye etc. 2 Make a flow chart showing the process of getting a fabric clothes from cotton plant.

Source: pinterest.com

Source: pinterest.com

Cotton is a natural fiber. Selection of fabric and trims as per the buyer specification. Spinning is a procedure of producingconverting fiber materials in yarns. May 18 2017 No comments. Yarn spinning is a process of making or converting fiber materials into yarnsIt is the primary Process of Textile Product.

Source: pinterest.com

Source: pinterest.com

There are three types of fabric manufacturing process. See more ideas about process flow chart process flow flow chart. 2 Download Print Instantly - 100 Free. For the manufacturing of knitted fabric process flow. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes.

Source: toppr.com

Source: toppr.com

Cotton Spinning process flow chart. Cotton is a soft fluffy staple fiber. Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. Spinning is a procedure of producingconverting fiber materials in yarns. 3 Coconut is also a fibre.

Source: textilecircle24.blogspot.com

Source: textilecircle24.blogspot.com

The printing flow chart depends on the fiber types. While you read the history of denim jeans It would be a good addition to knowing the denim fabric production processes and jeans manufacturing process. Flow Chart of Denim Production Process. Yarn production is a process of converting fibers into yarn. There are three types of fabric manufacturing process.

Cotton can be died also with vat dye direct dye sulfur dye mordant dye etc. Fabric dyeing - Google Search. Spinning is a procedure of producingconverting fiber materials in yarns. Table preparation Fabric plaited on the table Crack pasteclear apply with the help of screen Dry in air temp or hand dryer mc slight Printing paste apply with the help of screen Curing at 190ºc belt speed 2 mmin Delivery. Yarn production is a process of converting fibers into yarn.

Source: textileinfomedia.com

Source: textileinfomedia.com

The printing flow chart depends on the fiber types. During denim fabric manufacturing a process flow-chart should maintain to facilitate the fabric manufacturing process which is discussed in this article. Blending apron has sharp spikes the raise cotton until part of it is knocked off. Flow chart of Cotton Spinning process-. The printing flow chart depends on the fiber types.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

Procurement of fabric trims and accessories. 47 rows Wet processing flow chart for cotton. Yarn production is a process of converting fibers into yarn. 2 Download Print 100 Free. 21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties.

Source: researchgate.net

Source: researchgate.net

The denim manufacturing process is explained in the detail in this article. It is a natural and most popular fiber. For the manufacturing of knitted fabric process flow. They follow these steps to manufacture trousers listed in the sequence of occurrence -. Process Flow Of Printing Process For 100 Cotton Fabric.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title process flow chart of cotton fabric online by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.