Your Process flow chart of cotton fabric quality images are ready. Process flow chart of cotton fabric quality are a topic that is being searched for and liked by netizens today. You can Get the Process flow chart of cotton fabric quality files here. Download all free photos and vectors.

If you’re looking for process flow chart of cotton fabric quality images information connected with to the process flow chart of cotton fabric quality interest, you have visit the ideal site. Our site always provides you with hints for seeing the maximum quality video and image content, please kindly hunt and locate more enlightening video articles and images that match your interests.

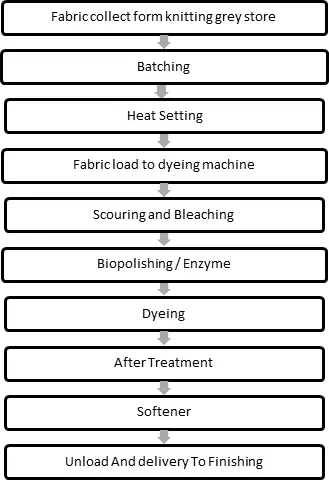

Process Flow Chart Of Cotton Fabric Quality. FABRIC DENSITY Yarns per inch YPI for wovens or stitches per inch SPI for knits. Definition of Label. We will guide you on how to place your essay help proofreading and editing your draft fixing the grammar spelling or formatting of your paper easily and cheaply. The humidity control standard is cotton fabric dyed with red azo dye.

Flow Chart Of Process Sequence Download Scientific Diagram From researchgate.net

Flow Chart Of Process Sequence Download Scientific Diagram From researchgate.net

Get 247 customer support help when you place a homework help service order with us. The same as temperature and pressure sensors measure process quality. It contains very fine threads and resists wrinkles keeps the skirts shape and has an almost transparent quality. See the Garment manufacturing process flow chart of a typical garment product. Prior to sourcing the fabric there are some pre-production processes handled by the factory merchandiser. The humidity control standard is cotton fabric dyed with red azo dye.

122 Padding finishing process 1 Process flow.

Get 247 customer support help when you place a homework help service order with us. Cotton Incorporated is a not-for-profit company providing the resources and research needed to help companies develop and market superior innovative and profitable cotton products. Once the fabric has been tautened covering processes vary. It is usually put on by brush to ensure the fibers are saturated. Every garment ensures the quality first because if garments are unable to ensure. The method of use is as follows.

Source: pinterest.com

Source: pinterest.com

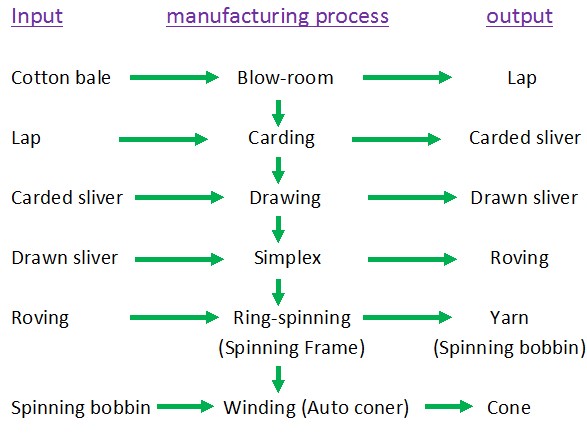

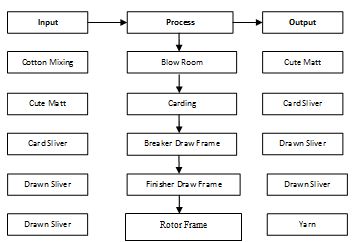

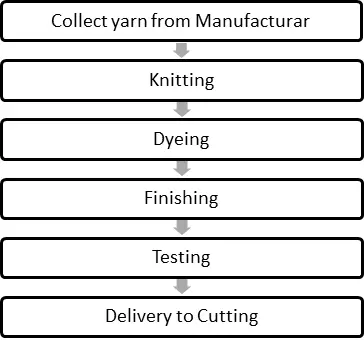

Spinning is a procedure of producingconverting fiber materials in yarns. The process is done following a specific SOP to check the specific items. The Left and Right Hand Chart is a process chart in which the activities of a workers hands or limbs are recorded in their relationship to one another. Ever thought about the processes involved. Garment manufacturing involves utmost care and perfection.

Source: textileinfomedia.com

Source: textileinfomedia.com

On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. It is a specialized form of process chart because it shows the two hands and sometimes the feet of the operative moving or static in relation to one another usually in relation to a time scale. Ever thought about the processes involved. Firstly is given manufacturing flow chart of denim fabric. Nylon fabric padding finishing liquid drying high.

Source: researchgate.net

Source: researchgate.net

Where Fabric is 100 cotton single jersey and fabric GSM is 160 and order quantity is 10000pcs. FIBER CONTENT The percent of fiber types that make up the fabric. A carded cotton ring spun yarn begins with a bale lay-down. Ever wondered about how your favourite t-shirt was made. You can entrust all your academic work to course help online for original and high quality papers submitted on time.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

For garments need to check the quality of fabric sewing thread trims etc. Prior to sourcing the fabric there are some pre-production processes handled by the factory merchandiser. Suppose one of the buyers has provided you the following measurement chart of a basic T-Shirt by mentioning the order quantity and fabric GSM. FIBER CONTENT The percent of fiber types that make up the fabric. YARN SIZE The size of the yarns.

Source: researchgate.net

Source: researchgate.net

The SPCSQC are used with in-line analyzer results to determine total batchcampaign quality and to display quality data to plant operators and management in real time. For example a fabric manufacturer buys yarn from a spinning mill. We will guide you on how to place your essay help proofreading and editing your draft fixing the grammar spelling or formatting of your paper easily and cheaply. The essential process of maintaining the quality of raw materials used during making the finished product is called inspection. Flow of the weaving process.

Source: ordnur.com

Source: ordnur.com

Once the fabric has been tautened covering processes vary. Flow of the weaving process. Brief of weaving process. The scale for denim goes between 5 and 32 ounces with the 5. It is usually put on by brush to ensure the fibers are saturated.

Source: pinterest.com

Source: pinterest.com

ECOFAST Pure doesnt have the unpleasant odor of other cationic pretreatments and can help. Before cotton arrives at the spinning mill to spin into thread and woven into the fabric it makes the journey from field to bale. Cotton needs about five months to grow from a planted seed to a ready plant. FABRIC NAME AKA a quality number. The apparel you sport is a product of hard work and expertise.

Source: in.pinterest.com

Source: in.pinterest.com

The processing of a cotton ring spun yarn must go through a carding machine. 122 Padding finishing process 1 Process flow. Some lightfastness requirements require method 3 and the quality requirements are intermediate levels such as 3-4. Nylon fabric padding finishing liquid drying high. Fabric spreading is important because of if fabric do not lay properly then outcome product after cutting was not correct.

Source: textilesgreen.in

Source: textilesgreen.in

ECOFAST Pure doesnt have the unpleasant odor of other cationic pretreatments and can help. Get 247 customer support help when you place a homework help service order with us. Where Fabric is 100 cotton single jersey and fabric GSM is 160 and order quantity is 10000pcs. The Left and Right Hand Chart is a process chart in which the activities of a workers hands or limbs are recorded in their relationship to one another. 122 Padding finishing process 1 Process flow.

Source: article.sapub.org

Source: article.sapub.org

FIBER CONTENT The percent of fiber types that make up the fabric. Yarn collection from spinning factory Warping Yarn dyeing. All our cheap essays are customized to meet your requirements and written from. The quality of all custom papers written by our team is important to us. FIBER CONTENT The percent of fiber types that make up the fabric.

Source: practicaltextile.com

Source: practicaltextile.com

Some lightfastness requirements require method 3 and the quality requirements are intermediate levels such as 3-4. We will guide you on how to place your essay help proofreading and editing your draft fixing the grammar spelling or formatting of your paper easily and cheaply. Flow Chart of Garment Manufacturing Process. In an automatic ginning process of cotton a modern machine is preferable. We can help bring sustainable fashion to lifewithout sacrificing color and quality.

Source: ordnur.com

Source: ordnur.com

For example a fabric manufacturer buys yarn from a spinning mill. All our cheap essays are customized to meet your requirements and written from. That is why we are so attentive to the application process and employ only those writers who can produce great essays and other kinds of written assignments. The method of use is as follows. Definition of Label.

Source: practicaltextile.com

Source: practicaltextile.com

122 Padding finishing process 1 Process flow. A garment label is a communicator between the buyer and the product. Firstly is given manufacturing flow chart of denim fabric. FABRIC WEAVE OR KNIT TYPE Examples would be plain weave or 3x1 twill for woven fabric or jersey for knit fabrics. FABRIC NAME AKA a quality number.

Source: researchgate.net

Source: researchgate.net

Modern Cotton Ginning Process. A garment label is a communicator between the buyer and the product. You can entrust all your academic work to course help online for original and high quality papers submitted on time. Flow Chart of Denim Production Process. YARN SIZE The size of the yarns.

Source: barnhardtcotton.net

Source: barnhardtcotton.net

We will guide you on how to place your essay help proofreading and editing your draft fixing the grammar spelling or formatting of your paper easily and cheaply. Get 247 customer support help when you place a homework help service order with us. Flow Chart of Garment Manufacturing Process. FIBER CONTENT The percent of fiber types that make up the fabric. Garment manufacturing involves utmost care and perfection.

Source: researchgate.net

Source: researchgate.net

Currently researchers are working on a cottonflax blend to create new yarns which will improve the feel of. Also called lawn cloth this type of fabric is made mostly of cotton and is similar to batiste but with a little more structure. The Left and Right Hand Chart is a process chart in which the activities of a workers hands or limbs are recorded in their relationship to one another. Ever wondered about how your favourite t-shirt was made. ECOFAST Pure doesnt have the unpleasant odor of other cationic pretreatments and can help.

Source: pinterest.com

Source: pinterest.com

The quality of all custom papers written by our team is important to us. We can help bring sustainable fashion to lifewithout sacrificing color and quality. A yard of 5-ounce denim actually weighs 5 ounces. The same as temperature and pressure sensors measure process quality. The Left and Right Hand Chart is a process chart in which the activities of a workers hands or limbs are recorded in their relationship to one another.

Source: researchgate.net

Source: researchgate.net

Other processes seal the fabric later. The process is done following a specific SOP to check the specific items. The same as temperature and pressure sensors measure process quality. The SPCSQC are used with in-line analyzer results to determine total batchcampaign quality and to display quality data to plant operators and management in real time. Before cotton arrives at the spinning mill to spin into thread and woven into the fabric it makes the journey from field to bale.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title process flow chart of cotton fabric quality by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.