Your Process flow chart of cotton fabric quantity images are ready in this website. Process flow chart of cotton fabric quantity are a topic that is being searched for and liked by netizens today. You can Download the Process flow chart of cotton fabric quantity files here. Download all royalty-free images.

If you’re searching for process flow chart of cotton fabric quantity images information linked to the process flow chart of cotton fabric quantity interest, you have pay a visit to the right site. Our site always gives you suggestions for seeking the maximum quality video and picture content, please kindly hunt and find more enlightening video articles and graphics that fit your interests.

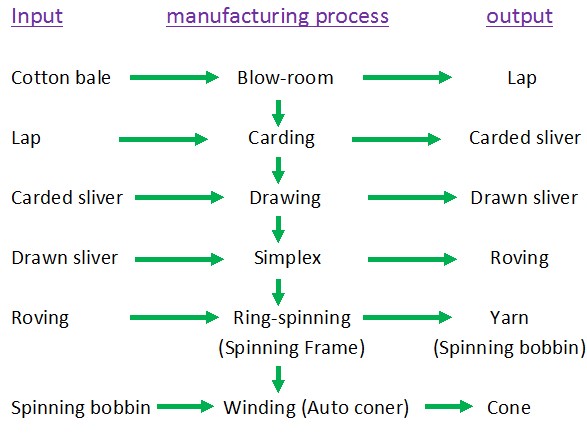

Process Flow Chart Of Cotton Fabric Quantity. From Raw Cotton to Cotton Fabrics The fabric usually used in the clothes we wear is produced through two processes. Fiber means any substance that have high length to width ratio. For Natural Fabrics Cotton Viscose Silk Wool. Strike offs abbreviated so are small fabric cuttings of printed fabrics.

100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Complete Practical Documentation 2021 From practicaltextile.com

100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Complete Practical Documentation 2021 From practicaltextile.com

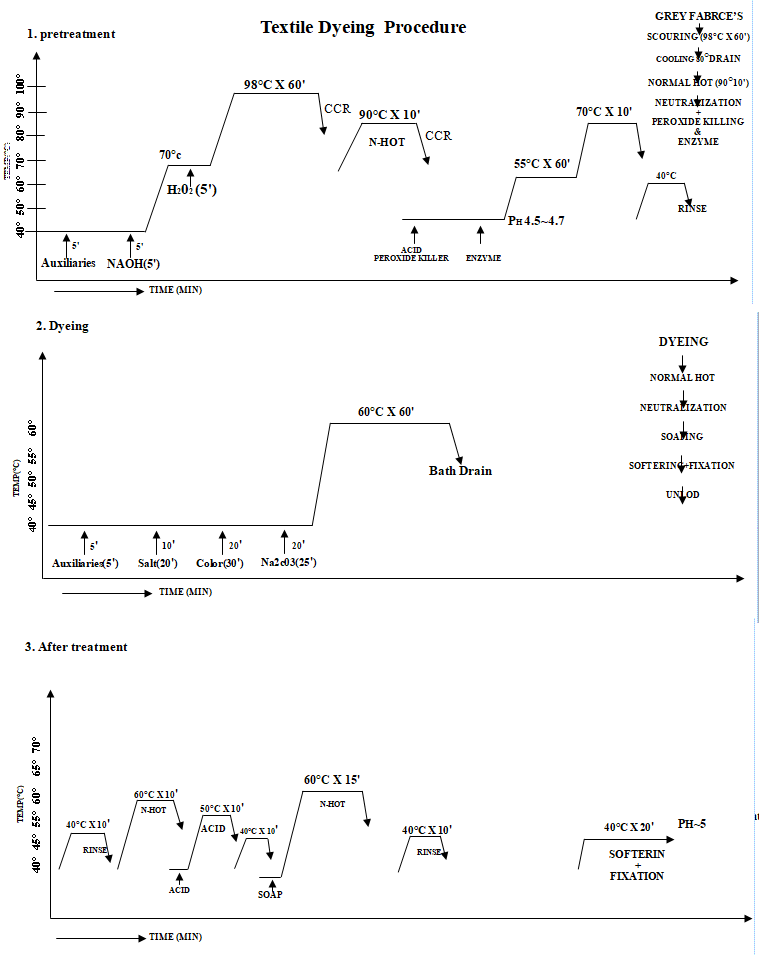

Cotton is wet out and packed into large cakes with a hole in the middle for a perfect visual imagine a Bundt cake. After placing an order buyer send the technical sheet and art-work of an order to the merchandiser. By this process gummy materials are removed. Process flow chart of Garments Merchandising. Here we will explain each process in detail using some illustrations. In this article I will explain all process separately.

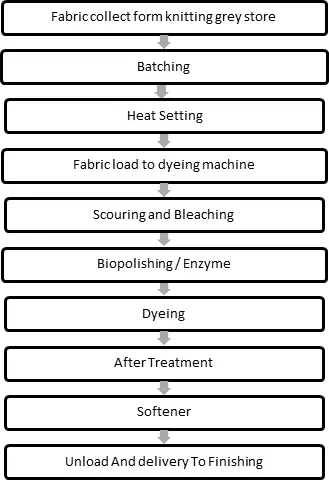

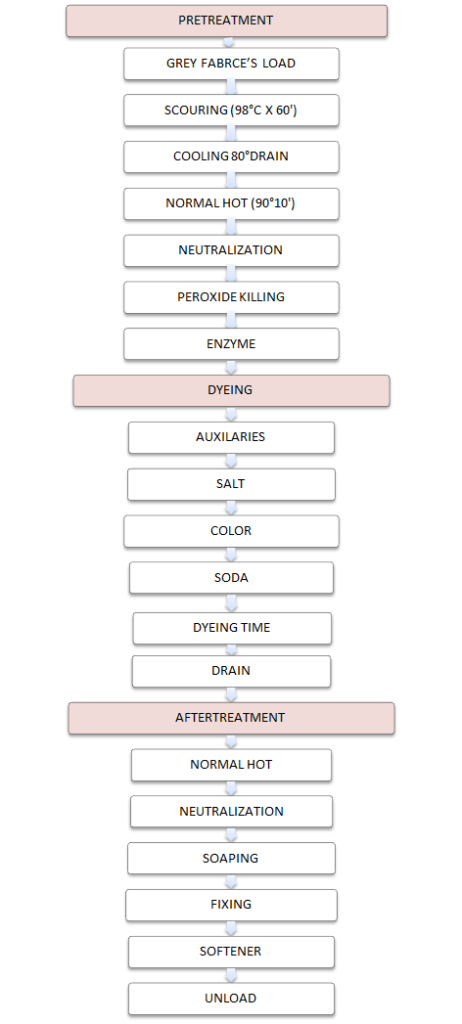

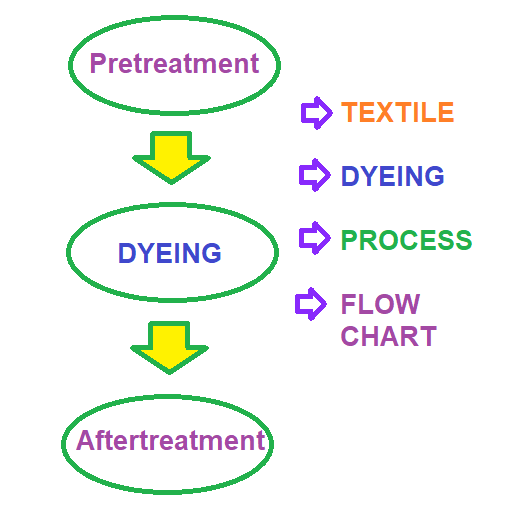

Flowchart of the flow chart of 100 cotton fabric dyeing is given below.

After placing an order buyer send the technical sheet and art-work of an order to the merchandiser. Also size materials removed by this process. In this article I will explain all process separately. Flow chart of Batching Section is given bellow. The purpose of a strike-off is to check that the print is the right size on register not blurry the correct colors etc. The complete process of making or producing Fabrics from fibres includes.

Source: toppr.com

Source: toppr.com

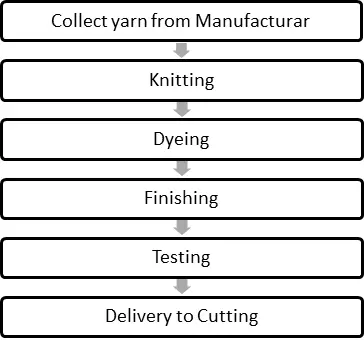

Cotton voile rayon linen satin and denim are different types of fabrics. Reactive dyes for cotton synthetic dyes for polyester are widely used in coloration textile industry. During this process the quantity received is. After placing an order buyer send the technical sheet and art-work of an order to the merchandiser. Yarn collection from spinning factory Warping Yarn dyeing.

Source: pinterest.com

Source: pinterest.com

But when we dye only the cotton fabric we use only caustic soda and hydrogen peroxide. Cotton printing is the most used process. Since the sales process often starts with the eyes merchandising typically involves presenting products in a visually. Also size materials removed by this process. Batch Process Flow Chart.

Source: pinterest.com

Source: pinterest.com

But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Cotton is the most popular useable fiber in the world. Here we will explain each process in detail using some illustrations. Processing of a Fibre into Fabric.

Source: pinterest.com

Source: pinterest.com

The goods are well inspected for all kinds of physical damage. Dyeingknit fabric Machine Shade Dyes and Chemicals Flow processfastness I. Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process. Merchandising means to promote and sell a product to the potential customerbuyer. These kiers can be heated and pressurized to speed up the wet purification process.

Source: practicaltextile.com

Source: practicaltextile.com

Generally in denim fabric manufacturing cotton are used and in case of dye indigo dyes are used for dyeing of denim fabric. April 30 2015 by textile-flowchart. Batch Process Flow Chart. Generally in denim fabric manufacturing cotton are used and in case of dye indigo dyes are used for dyeing of denim fabric. The goods are well inspected for all kinds of physical damage.

Source: practicaltextile.com

Source: practicaltextile.com

Make A Flow Chart To Show The Process Innvoled In Making Fabrics From Cotton Fibers Science Fibre Fabric 6921350 Meritnation. Firstly is given manufacturing flow chart of denim fabric. It is a natural and most popular fiber. Cotton is a natural fiber. Also size materials removed by this process.

Source: researchgate.net

Source: researchgate.net

They follow these steps to manufacture trousers listed in the sequence of occurrence -. 100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. By this process gummy materials are removed. During this process the quantity received is. The cotton cakes are then lowered down into the kier and it is closed.

Source: researchgate.net

Source: researchgate.net

From Raw Cotton to Cotton Fabrics The fabric usually used in the clothes we wear is produced through two processes. Procurement of fabric trims and accessories. Desizing is the second steps of pre-treatment. Fabric consider as a major raw material in the garments manufacturing process. Since the sales process often starts with the eyes merchandising typically involves presenting products in a visually.

Source: practicaltextile.com

Source: practicaltextile.com

The complete process of making or producing Fabrics from fibres includes. The printing flow chart depends on the fiber types. Batch Process Flow Chart. 100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. But when we dye only the cotton fabric we use only caustic soda and hydrogen peroxide.

Source: pinterest.com

Source: pinterest.com

Strike offs abbreviated so are small fabric cuttings of printed fabrics. But when we dye only the cotton fabric we use only caustic soda and hydrogen peroxide. Reactive dyes for cotton synthetic dyes for polyester are widely used in coloration textile industry. The process of trouser manufacturing when done by a full-package manufacturer involved the following processes. For Natural Fabrics Cotton Viscose Silk Wool.

Source: in.pinterest.com

Source: in.pinterest.com

Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Flow Chart of Cotton Dyeing Process. Lab dips and strike offs are used to approve the colors and prints before sample fabric is made. Flow chart of Batching Section is given bellow. The purpose of a strike-off is to check that the print is the right size on register not blurry the correct colors etc.

Source: researchgate.net

Source: researchgate.net

Design is provided by the buyer. In this article I will explain all process separately. Normally reactive dye is used for dyeing cotton fiber. The characteristics of a fabric depend upon the type of fibre used and the treatment applied to them. Process Flow Of Printing Process For 100 Cotton Fabric.

Source: practicaltextile.com

Source: practicaltextile.com

Cotton voile rayon linen satin and denim are different types of fabrics. Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. Yarn collection from spinning factory Warping Yarn dyeing. It is a natural and most popular fiber. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

Fabric received and stored Fabric divided according to width or tube diameter after buyers recommendation Supervisor batches the fabric according to quantity by calculation Inspection. During this process the quantity received is. Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process. Flow chart of Batching Section is given bellow. A special dyeing process is followed for Tencel cotton blend fabric.

Source: researchgate.net

Source: researchgate.net

The process flow of Digital Printing on all Natural fabrics. The silver produced. Cotton can be died also with vat dye direct dye sulfur dye mordant dye etc. After carding the process is continued by drawing which includes attenuating in spinning mills. The printing flow chart depends on the fiber types.

Source: researchgate.net

Source: researchgate.net

Cotton is a natural fiber. The process by which loose hairy and projecting fibers are removed is called Singeing. In this article I will explain all process separately. For Natural Fabrics Cotton Viscose Silk Wool. Introduction Dyeing is a process of coloration of textile fabric by using some required dyes chemical according to the specified shade color order.

Source: practicaltextile.com

Source: practicaltextile.com

The cotton cakes are then lowered down into the kier and it is closed. For cotton Tencel blends fabric special multifunctional scouring agent soda ash light and hydrogen peroxide used for scouring and bleaching here. By this process gummy materials are removed. Spinning is a procedure of producingconverting fiber materials in yarns. The characteristics of a fabric depend upon the type of fibre used and the treatment applied to them.

Source: researchgate.net

Source: researchgate.net

Strike offs abbreviated so are small fabric cuttings of printed fabrics. Fiber means any substance that have high length to width ratio. Dyeingknit fabric Machine Shade Dyes and Chemicals Flow processfastness I. Spinning is a procedure of producingconverting fiber materials in yarns. Fabric consider as a major raw material in the garments manufacturing process.

This site is an open community for users to do submittion their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title process flow chart of cotton fabric quantity by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.