Your Process flow chart of cotton fabric softener images are available in this site. Process flow chart of cotton fabric softener are a topic that is being searched for and liked by netizens today. You can Get the Process flow chart of cotton fabric softener files here. Download all free photos.

If you’re looking for process flow chart of cotton fabric softener pictures information connected with to the process flow chart of cotton fabric softener topic, you have visit the ideal site. Our site always provides you with suggestions for seeking the maximum quality video and image content, please kindly hunt and locate more informative video articles and images that match your interests.

Process Flow Chart Of Cotton Fabric Softener. Water filling in dyeing machine Fabric loading Hot Wash 80 o C 10 min Drain Water. Viscose needs reactive dyes just like cotton does. These processes are carried out to impart a particular property related to that. Ad Get Simple Templates To Create Your Flow Chart In Minutes.

Flow Chart Of Textile Fabric Manipulation Flow Chart Textiles From pinterest.com

Flow Chart Of Textile Fabric Manipulation Flow Chart Textiles From pinterest.com

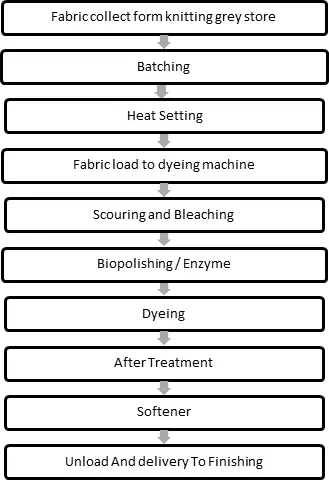

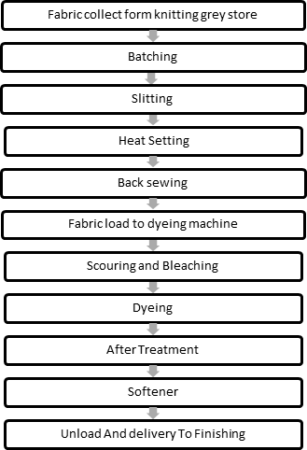

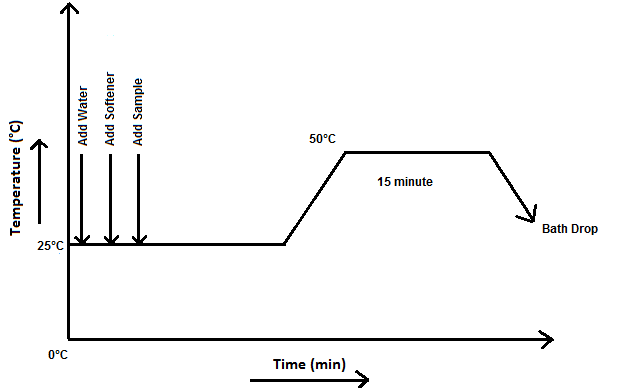

Process Flow ChartSequence of Dyeing Lab. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Ad Get Simple Templates To Create Your Flow Chart In Minutes. Application of softening agent to cotton fabric by exhaust method. Procedure for 100 Cotton Fabric. Acetic acid to adjust the pH.

Softener is adding for make fabric soft improve handfeel properties.

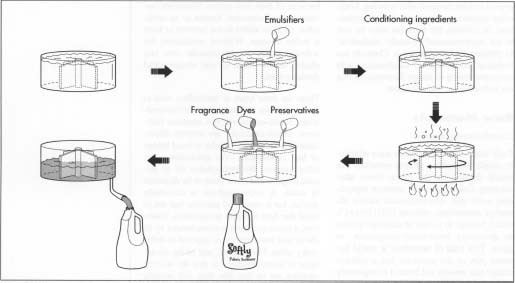

Acetic acid to adjust. The process involves forming a thick phase aqueous dispersion of the quaternary ammonium salt with the silicone or organic oil and further admixing additional water to form a fabric softener composition. Removal of softener spot from the Fabric is a washing process which is done in the dyeing bath. These processes are carried out to impart a particular property related to that. Viscose needs reactive dyes just like cotton does. Fabric consider as a major raw material in the garments manufacturing process.

Source: researchgate.net

Source: researchgate.net

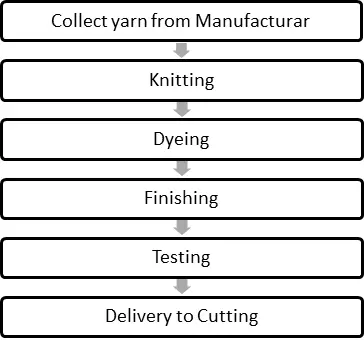

Otherwise collar to body portion difference will be observed more but according to customer demand it has to do cost-wise economical also. Measure out the desired amount of detergent 4 Pour the detergent into the washer 5 Determine if fabric softener is needed. Knitted fabrics undergo a series of different chemical processing treatments. Spinning is a procedure of producingconverting fiber materials in yarns. The process involves forming a thick phase aqueous dispersion of the quaternary ammonium salt with the silicone or organic oil and further admixing additional water to form a fabric softener composition.

Source: textileflowchart.com

Source: textileflowchart.com

Turquoise is very sensitive color. Actually viscose dyeing process is same as cotton spandex fabric. This sample is not washed. Are clothes durable like cotton d. Visualize Your Ideas With A Flow Chart.

Source: practicaltextile.com

Source: practicaltextile.com

On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. Fabric consider as a major raw material in the garments manufacturing process. Viscose Fabric Dyeing. Napping and sueding refer to Cotton Incorporateds technical bulletins Napping of Cotton Fabrics-TRI 3006 and Sueding of Cotton Fabrics-TRI 3010 Calendering is a process in which the fabric is squeezed between rollers to flatten the surface. After carding the process is continued by drawing which includes attenuating in spinning mills.

Source: researchgate.net

Source: researchgate.net

Acetic acid to adjust. At first dyeing is performed in dyeing laboratory and then starting for bulk production. Ad Get Simple Templates To Create Your Flow Chart In Minutes. This sample is not washed. The invention relates to a thickened fabric softener comprising the following components in parts by weight.

Source: practicaltextile.com

Source: practicaltextile.com

Required amount of water was taken into the machine. 1-8 parts of softener 01-2 parts of thickening agent 005-03 parts of preservative 9885-897 parts of de-ionized water. The silver produced. Softener dosing is done for 30min and run for 10min. If cloths are durable fabrics like cotton then go to step 11 else go to step 12.

Source: academia.edu

Source: academia.edu

Fabric consider as a major raw material in the garments manufacturing process. If No use cold water Determine Washing cycle f. Viscose needs reactive dyes just like cotton does. 11 Select hot water. Softener enters into the polymer chain of molecules and rearranges them into new order.

Source: pinterest.com

Source: pinterest.com

Basic function of Softener is to soft the fabric. The materials and chemicals used in the stenter machine process for TC fabric 100 Cotton fabric CVC fabric and for Water Repellent fabric are described below. A process is disclosed for preparing a fabric softener composition containing a quaternary ammonium salt and a silicone or organic oil. Then sample is cut check. A adding the de-ionized water to a water phase boiler.

Source: diutestudents.blogspot.com

Source: diutestudents.blogspot.com

Softener is adding for make fabric soft improve handfeel properties. 100 Cotton Fabric soft Softener Additive. For this purpose cotton fabric was treated with a. A adding the de-ionized water to a water phase boiler. 21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties.

Source: practicaltextile.com

Source: practicaltextile.com

On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. Acetic acid to adjust the pH. Process Flow Chart for 100 Cotton Knit Fabric Turquoise Color Posted on 0519 by Unknown. Process sequence of viscose fabric dyeing is given below. The invention relates to a thickened fabric softener comprising the following components in parts by weight.

Source: researchgate.net

Source: researchgate.net

14 Select gentle cycle. Such as scouring bleaching dyeing hydro extractor or dewatering stitching stentering compacting softener padding relax drying final inspection. If not go straight to step 6 c. If needed measure and add. Napping and sueding refer to Cotton Incorporateds technical bulletins Napping of Cotton Fabrics-TRI 3006 and Sueding of Cotton Fabrics-TRI 3010 Calendering is a process in which the fabric is squeezed between rollers to flatten the surface.

Source: researchgate.net

Source: researchgate.net

Cotton Dyeing Steps with Curve. The aim of this work was to investigate the effects of ultrasonic energy on the processing of cotton with a cationic softener. If No use cold water Determine Washing cycle f. Then sample is cut check. To learn about the process of finishing any fabric with a softening agent.

Source: madehow.com

Source: madehow.com

The aim of this work was to investigate the effects of ultrasonic energy on the processing of cotton with a cationic softener. The hand of the fabric will often become softer with a calender especially after chemical. The process involves forming a thick phase aqueous dispersion of the quaternary ammonium salt with the silicone or organic oil and further admixing additional water to form a fabric softener composition. Softener added and run time 30 min. Visualize Your Ideas With A Flow Chart.

Source: textile4home.blogspot.com

Source: textile4home.blogspot.com

Name of the Experiment. A lots of work is done in the dyeing. 12 Choose the laundry cycle. Determine if fabric softener is needed. Viscose Fabric Dyeing.

Source: practicaltextile.com

Source: practicaltextile.com

A process is disclosed for preparing a fabric softener composition containing a quaternary ammonium salt and a silicone or organic oil. Dosing softener 5min. The softener is a finishing agent that when applied to textile material improves its handle. 1-8 parts of softener 01-2 parts of thickening agent 005-03 parts of preservative 9885-897 parts of de-ionized water. If No use cold water Determine Washing cycle f.

Source: pinterest.com

Source: pinterest.com

If needed measure and add. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Turquoise is very sensitive color. Typical preparation processes used for cotton and cotton blend yarns and fabrics. A lots of work is done in the dyeing.

Source: researchgate.net

Source: researchgate.net

Softener spot is a dyeing fault which is occurred during the application of softener to the fabric in dyeing bath or de-watering machineWhen this type of fault is found in a dyed fabric then it needs to make free the dyed fabric from the softener spots. If needed measure and add. Turquoise is very sensitive color. Dosing softener 5min. Actually viscose dyeing process is same as cotton spandex fabric.

Source: pinterest.com

Source: pinterest.com

If Yes use hot water e. Softener enters into the polymer chain of molecules and rearranges them into new order. Measure out the desired amount of detergent 4 Pour the detergent into the washer 5 Determine if fabric softener is needed. If clothes are temperature sensitive move to step 7 if not move to step 8. If not go straight to step 6 c.

Source: pinterest.com

Source: pinterest.com

The silver produced. A lots of work is done in the dyeing. Process flow chart of weaving technology is given below. Softener enters into the polymer chain of molecules and rearranges them into new order. Process Flow Chart of Viscose Fabric Dyeing.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title process flow chart of cotton fabric softener by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.