Your Process flow chart of cotton fabric x ray images are ready. Process flow chart of cotton fabric x ray are a topic that is being searched for and liked by netizens now. You can Find and Download the Process flow chart of cotton fabric x ray files here. Get all free photos.

If you’re looking for process flow chart of cotton fabric x ray pictures information connected with to the process flow chart of cotton fabric x ray interest, you have come to the right site. Our website frequently gives you hints for viewing the maximum quality video and image content, please kindly hunt and find more enlightening video content and graphics that match your interests.

Process Flow Chart Of Cotton Fabric X Ray. May 18 2017 No comments. It is the process to remove neps warp end breakage. It is a natural and most popular fiber. Flow chart of synthetic process of man-made fiber.

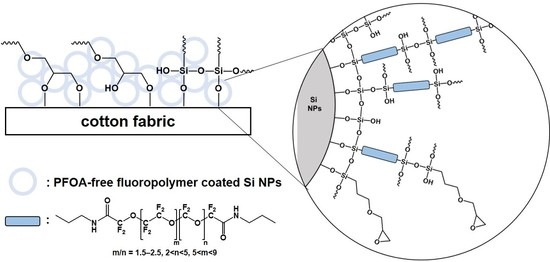

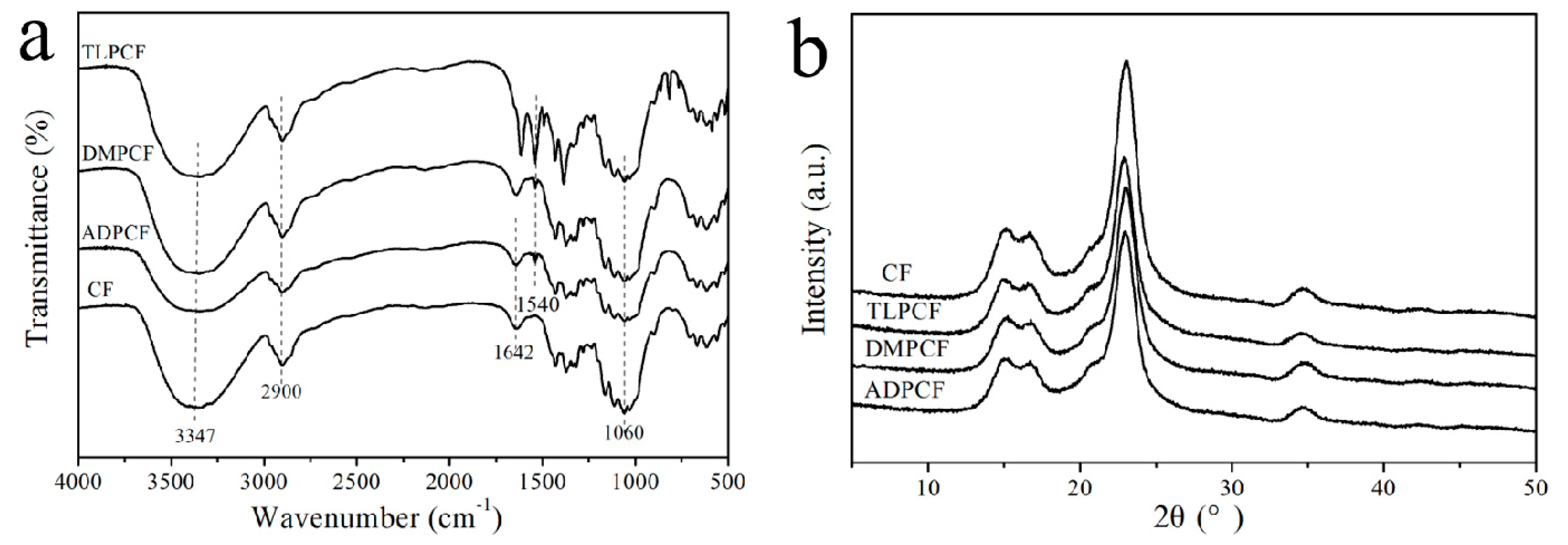

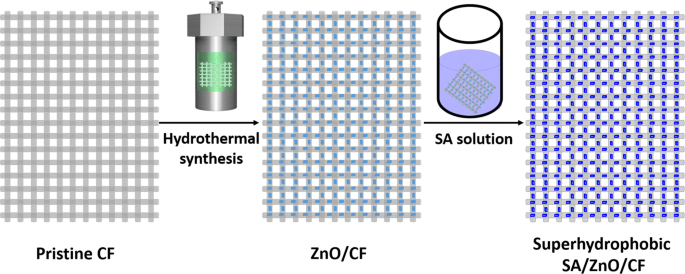

Polymers Free Full Text Micro Nanostructured Coating For Cotton Textiles That Repel Oil Water And Chemical Warfare Agents Html From mdpi.com

Polymers Free Full Text Micro Nanostructured Coating For Cotton Textiles That Repel Oil Water And Chemical Warfare Agents Html From mdpi.com

But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. This process is known. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Yarn Path Diagram of V-bed Flat MC. Cotton printing is the most used process. Follow chart is part and parcel in textile industry.

Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc.

Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. Process Flow Of Printing Process For 100 Cotton Fabric. A flow chart showing the processes involved in wet processing of the fabric in the fabric dyeing unit is shown in Figure 3. The silver produced. The main aim of wet processing is take a gray cloth and make them finished fabric as it can make garments by take them into too many wet processing technique. A process flow chart.

Source: mdpi.com

Source: mdpi.com

After carding the process is continued by drawing which includes attenuating in spinning mills. Yarn Path Diagram of V-bed Flat MC. We wear different garment for different purposes. Sisson analyzed a cotton yarn treated with a wide range of alkaline concentrations and processing temperatures with X-ray diffraction divided the results into the three divisions of complete mercerization partial mercerization and un-mercerized and created a chart showing the relationship between the alkaline concentration and the temperature. Fabric consider as a major raw material in the garments manufacturing process.

Source: sciencedirect.com

Source: sciencedirect.com

Complete Dyeing process of 100 cotton fabric Cotton is most popular natural fiber around the world. Flow chart of synthetic process of man-made fiber. May 18 2017 No comments. April 30 2015 by textile-flowchart. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes.

Source: mdpi.com

Source: mdpi.com

Spinning is a procedure of producingconverting fiber materials in yarns. Combed cotton spinning process is another important spinning process of cotton. Denim is a durable cotton twill textile in which the weft passes under two or more warp threads. Cotton is a soft fluffy staple fiber. It is the process to remove neps warp end breakage.

Source: researchgate.net

Source: researchgate.net

Normally reactive dye is used for dyeing cotton fiber. Flowchart of the flow chart of 100 cotton fabric dyeing is given below. April 30 2015 by textile-flowchart. After manufacturing fabric it is inspected in an inspection Table. You can edit this template on Createlys Visual Workspace to get started quickly.

Source: researchgate.net

Source: researchgate.net

Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. The flow chart of cotton dyeing process of cotton is given below. See more ideas about process flow chart process flow flow chart. May 18 2017 No comments. Flow chart of Cotton Spinning process-.

Source: researchgate.net

Source: researchgate.net

Yarn Path Diagram of V-bed Flat MC. Fabric consider as a major raw material in the garments manufacturing process. Wet processing flow chart for cotton. After carding the process is continued by drawing which includes attenuating in spinning mills. A process flow chart.

Source: researchgate.net

Source: researchgate.net

It is one of the most easily dyeable fibers. During the sizing process the fabric is stiffened by adding sizing. But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. Sorting performance can be maximized by using techniques including X-ray detection. Normally the thickness of a yarn is expressed in terms of countCount may be defined as the number which expresses the fineness or coarseness of a yarn.

Source: researchgate.net

Source: researchgate.net

It is one of the most easily dyeable fibers. Sisson analyzed a cotton yarn treated with a wide range of alkaline concentrations and processing temperatures with X-ray diffraction divided the results into the three divisions of complete mercerization partial mercerization and un-mercerized and created a chart showing the relationship between the alkaline concentration and the temperature. Natural fiber such as- cotton wool and silk contains various types of impurities for this reason it is required to remove the impurities before dyeing and printing process. Fiber means any substance that have high length to width ratio. Flow Chart of Wet processing for Knit Fabric 23.

Source: onlinelibrary.wiley.com

Source: onlinelibrary.wiley.com

Combing is done after carding. Wet processing flow chart for cotton. A flow chart showing the processes involved in wet processing of the fabric in the fabric dyeing unit is shown in Figure 3. See more ideas about process flow chart process flow flow chart. The thickness of the yarn varies to a wide range.

Source: mdpi.com

Source: mdpi.com

The printing flow chart depends on the fiber types. It is one of the most easily dyeable fibers. 100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. Combed cotton spinning process is another important spinning process of cotton. Combed yarn is finer than carded or rotor yarn.

Source: researchgate.net

Source: researchgate.net

The original way of wet processing is most important. After carding the process is continued by drawing which includes attenuating in spinning mills. During the sizing process the fabric is stiffened by adding sizing. It is one of the most easily dyeable fibers. A process flow chart.

Source: researchgate.net

Source: researchgate.net

Combing is done after carding. It is the process to remove neps warp end breakage. You can edit this template on Createlys Visual Workspace to get started quickly. Normally reactive dye is used for dyeing cotton fiber. Yarn spinning is a process of making or converting fiber materials into yarnsIt is the primary Process of Textile Product.

Source: researchgate.net

Source: researchgate.net

Cotton is a natural fiber. Higher count yarn is produced by this process. On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. Complete Dyeing process of 100 cotton fabric Cotton is most popular natural fiber around the world. Flowchart of the flow chart of 100 cotton fabric dyeing is given below.

Source: mdpi.com

Source: mdpi.com

May 18 2017 No comments. Process Flow Of Printing Process For 100 Cotton Fabric. April 30 2015 by textile-flowchart. 100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. Flow Chart of Wet processing for Knit Fabric 23.

Source: link.springer.com

Source: link.springer.com

Combing is done for adding extra features to the fibers. Wet processing is a two single word but means. Normally the thickness of a yarn is expressed in terms of countCount may be defined as the number which expresses the fineness or coarseness of a yarn. Normally reactive dye is used for dyeing cotton fiber. Cotton can be died also with vat dye direct dye sulfur dye mordant dye etc.

Source: researchgate.net

Source: researchgate.net

Wet processing flow chart for cotton. Cotton is a soft fluffy staple fiber. Natural fiber such as- cotton wool and silk contains various types of impurities for this reason it is required to remove the impurities before dyeing and printing process. Production Flow Chart of Wet Processing for Woven Fabric 21. Wet processing flow chart for cotton.

Source: researchgate.net

Source: researchgate.net

Make A Flow Chart To Show The Process Innvoled In Making Fabrics From Cotton Fibers Science Fibre Fabric 6921350 Meritnation. Environmental analysis of a cotton yarn supply Chain This study compares the environmental impacts related. This is ideal follow chart for cotton dyeing which is help somebody to know about cotton fabric or yarn dying. Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. Sisson analyzed a cotton yarn treated with a wide range of alkaline concentrations and processing temperatures with X-ray diffraction divided the results into the three divisions of complete mercerization partial mercerization and un-mercerized and created a chart showing the relationship between the alkaline concentration and the temperature.

Source: researchgate.net

Source: researchgate.net

Wet processing process makes a fabric more useable more fineness and more attractive to the consumer. It is a natural and most popular fiber. Flow chart of synthetic process of man-made fiber. The thickness of the yarn varies to a wide range. Denim is a durable cotton twill textile in which the weft passes under two or more warp threads.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site adventageous, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title process flow chart of cotton fabric x ray by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.