Your Process flow chart of cotton fabric youtube images are ready. Process flow chart of cotton fabric youtube are a topic that is being searched for and liked by netizens today. You can Download the Process flow chart of cotton fabric youtube files here. Download all free images.

If you’re looking for process flow chart of cotton fabric youtube pictures information connected with to the process flow chart of cotton fabric youtube interest, you have come to the right site. Our site always gives you suggestions for seeing the highest quality video and image content, please kindly surf and find more informative video content and graphics that fit your interests.

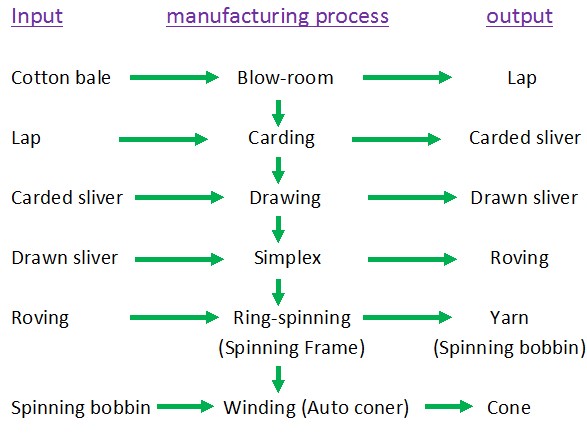

Process Flow Chart Of Cotton Fabric Youtube. You can read some article below. Flow chart of yarn spinning technology are described given below. Some extra steps are added for combed yarn manufacturing. Fabric consider as a major raw material in the garments manufacturing process.

Flow Chart Of Textile Manufacturing Process Youtube From youtube.com

Flow Chart Of Textile Manufacturing Process Youtube From youtube.com

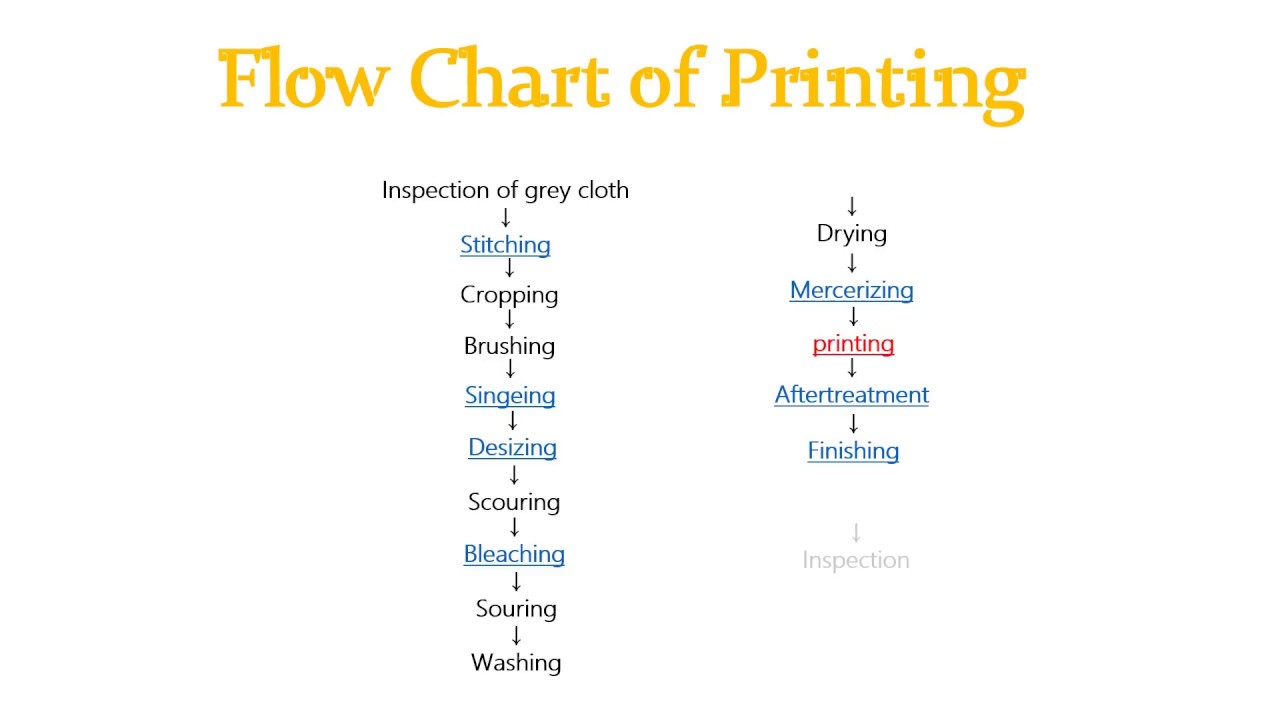

Normally the thickness of a yarn is expressed in terms of countCount may be defined as the number which expresses the fineness or coarseness of a yarn. If the cloth is to be finished white or is to be given surface ornamentation all-natural color must be removed by bleaching. Some extra steps are added for combed yarn manufacturing. And orders Production officer and Technical in- charge. Cotton printing is the most used process. Normally reactive dye is used for dyeing cotton fiber.

Cotton can be died also with vat dye direct dye sulfur dye mordant dye etc.

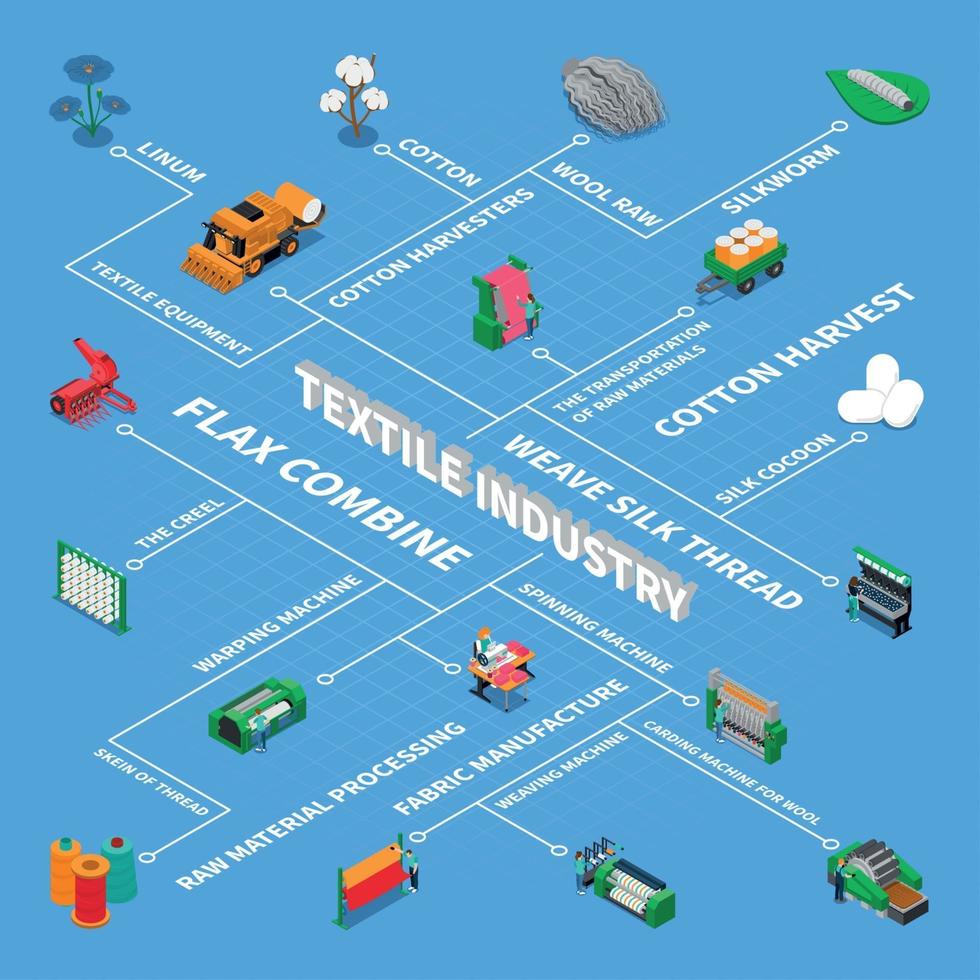

Each process of textile manufacturing is maintained with pre-defined sequences and the textile engineers usually follow the flow chart step by step to produce the better textile products that have been ordered by buyer. Flowchart of the flow chart of 100 cotton fabric dyeing is given below. Flow Chart of Cotton Dyeing Process. Combed yarn is finer than carded or rotor yarn. You can read some article below. Cotton printing is the most used process.

Source: youtube.com

Source: youtube.com

Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. Check the fabric if enzyme action is proper. 100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. Combed yarn is finer than carded or rotor yarn. The enzyme is added run for 30 minutes.

Source: snapsolve.com

Source: snapsolve.com

Flow chart of yarn spinning technology are described given below. Combing is done after carding. Cotton is a soft fluffy staple fiber. This process is known. This is also necessary if discoloration or stains have occurred during the previous manufacturing process.

Its complete video of fiber to garments manufacturing processSubscribe To My Channel. Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. Previous article I have discussed on process flowchart of cotton spinning. It can be done in the yarn stage as well as in the constructed fabric. Cotton is a natural fiber.

Source: pinterest.com

Source: pinterest.com

You can find us. Weaving is done by the interlacement of these two types of yarn. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Process flow chart of weaving technology is given below. This is also necessary if discoloration or stains have occurred during the previous manufacturing process.

Nylon fabric dyeing process- For practical use. Flowchart of the flow chart of 100 cotton fabric dyeing is given below. In yarn dyeing floor. Wet processing flow chart for cotton. The main aim of wet processing is take a gray cloth and make them finished fabric as it can make garments by take them into too many wet processing technique.

Source: youtube.com

Source: youtube.com

Combed cotton spinning process is another important spinning process of cotton. Above weaving flow chart is mostly used for cotton and jute fabric. Nylon fabric dyeing process- For practical use. Combing is done after carding. This is the basic and primary flowchart of textile.

Source: youtube.com

Source: youtube.com

It is one of the most easily dyeable fibers. We wear different garment for different purposes. It is one of the most easily dyeable fibers. Complete Video of Textile manufacturing Process. One is the process flow chart of cotton spinning and another is a flow chart of product spinning.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

Weaving is done by the interlacement of these two types of yarn. Combed yarn is finer than carded or rotor yarn. There are two types of flow chart of ring spinningcotton spinning. Conclusion Knit fabric finishing flow chart. The fabric is loaded in a machine fills with required water.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

You can read some article below. Denim is a durable cotton twill textile in which the weft passes under two or more warp threads. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. Cotton can be died also with vat dye direct dye sulfur dye mordant dye etc. Flow Chart of Cotton Bleaching Process.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

Conclusion Knit fabric finishing flow chart. Process for cotton yarn can be vary depending on the individual procedure of a textile engineer or a dyeing masterI have given a process flow chart for 100 cotton dyeing. Each process of textile manufacturing is maintained with pre-defined sequences and the textile engineers usually follow the flow chart step by step to produce the better textile products that have been ordered by buyer. The thickness of the yarn varies to a wide range. It is one of the most easily dyeable fibers.

Source: textileinfomedia.com

Source: textileinfomedia.com

Normally the thickness of a yarn is expressed in terms of countCount may be defined as the number which expresses the fineness or coarseness of a yarn. Make A Flow Chart To Show The Process Innvoled In Making Fabrics From Cotton Fibers Science Fibre Fabric 6921350 Meritnation. This sequence is applicable for producing light shade less than 1. If not then increase the time. Flow Chart of Cotton Bleaching Process.

Source: vecteezy.com

Source: vecteezy.com

100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. Flow Chart of Cotton Dyeing Process. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Denim is a durable cotton twill textile in which the weft passes under two or more warp threads. Wet processing flow chart for cotton.

Source: youtube.com

Source: youtube.com

Check the fabric if enzyme action is proper. Process for cotton yarn can be vary depending on the individual procedure of a textile engineer or a dyeing masterI have given a process flow chart for 100 cotton dyeing. Cotton is passed from bales and then to apron. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Process Flow Of Printing Process For 100 Cotton Fabric.

Source: bigdbiz.com

Source: bigdbiz.com

Weaving is done by the interlacement of these two types of yarn. Combing is done for adding extra features to the fibers. Those garment have not got miracley but those have to pass many stages from textiles fiber example. Process flow chart of weaving technology is given below. The flow process chart is merely a diagram of production sequence without regard to the time and space relationships in the sequence.

Source: pinterest.com

Source: pinterest.com

Cotton can be died also with vat dye direct dye sulfur dye mordant dye etc. Cotton is a soft fluffy staple fiber. 100 Cotton Fabric Knitting Dyeing Process Reactive Dye Flow Chart With Plete Practical Doentation 2021. Flow Chart of Cotton Bleaching Process. There are two types of flow chart of ring spinningcotton spinning.

Source: pinterest.com

Source: pinterest.com

The thickness of the yarn varies to a wide range. Denim is a durable cotton twill textile in which the weft passes under two or more warp threads. The flow chart of cotton dyeing process of cotton is given below. Fabric consider as a major raw material in the garments manufacturing process. Previous article I have discussed on process flowchart of cotton spinning.

Source: pinterest.com

Source: pinterest.com

Combing is done after carding. Process for cotton yarn can be vary depending on the individual procedure of a textile engineer or a dyeing masterI have given a process flow chart for 100 cotton dyeing. Combed cotton spinning process is another important spinning process of cotton. The enzyme is added run for 30 minutes. One is the process flow chart of cotton spinning and another is a flow chart of product spinning.

Source: pinterest.com

Source: pinterest.com

We wear different garment for different purposes. Combing is done for adding extra features to the fibers. Specially for higher costly fabric. The enzyme is added run for 30 minutes. Each process of textile manufacturing is maintained with pre-defined sequences and the textile engineers usually follow the flow chart step by step to produce the better textile products that have been ordered by buyer.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title process flow chart of cotton fabric youtube by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.