Your Process flow chart of cotton fabric zone images are ready. Process flow chart of cotton fabric zone are a topic that is being searched for and liked by netizens now. You can Get the Process flow chart of cotton fabric zone files here. Download all free photos and vectors.

If you’re looking for process flow chart of cotton fabric zone pictures information connected with to the process flow chart of cotton fabric zone keyword, you have visit the right site. Our site always gives you suggestions for downloading the highest quality video and image content, please kindly hunt and find more enlightening video content and images that fit your interests.

Process Flow Chart Of Cotton Fabric Zone. At this point in cotton processing all of the fibers impurities and coloring bodies have been removed and the cotton fibers are pure cellulose. This process is known. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. Finishing accentuate or inhibiti some characteristic of fabric.

Flow Chart Of Textile Fabric Manipulation Flow Chart Textiles From pinterest.com

Flow Chart Of Textile Fabric Manipulation Flow Chart Textiles From pinterest.com

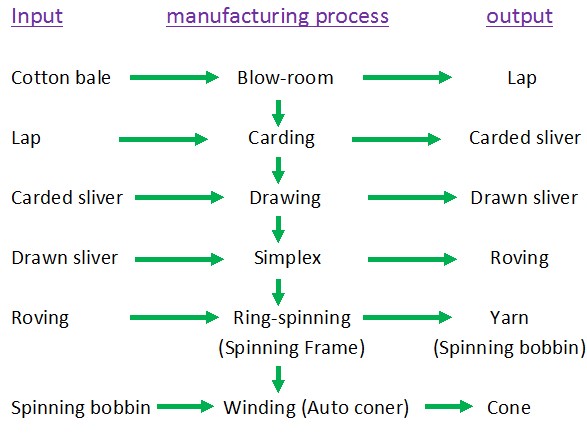

Cotton 4 11 Cotton Production Harvesting 5 12 Seed Cotton Storage 6 13 Ginning 6-7 2 Cotton Yarn Manufacturing Process 8 21 Textile Yarn Manufacturing 8 22 Carded yarn manufacturing flow chart 9 23 Combed yarn manufacturing flow chart 9-10 24 Blow room 11 241 Basic operations involved in the blow room 11 242 Objects of blow room 12. At first spinning process is begun with converting highly compressed cotton in bales into the form of a thoroughly loosened opened and cleaned state. It increase life and durability of the fabric. Dyeing of Aloe gel treated cotton. Here we will explain each process in detail using some illustrations. The spinning process where raw cotton is turned into thread and the weaving process where the thread is woven into fabric.

Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same.

Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. In a spinning mill those steps of the processing carried out in the blow room. 21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties. It is a natural and most popular fiber. At this point in cotton processing all of the fibers impurities and coloring bodies have been removed and the cotton fibers are pure cellulose.

Source: practicaltextile.com

Source: practicaltextile.com

Finally level the desized fabric sample Table 1. Process Flow Of Printing Process For 100 Cotton Fabric. The main aim of wet processing is take a gray. The printing flow chart depends on the fiber types. In a spinning mill those steps of the processing carried out in the blow room.

Source: pinterest.com

Source: pinterest.com

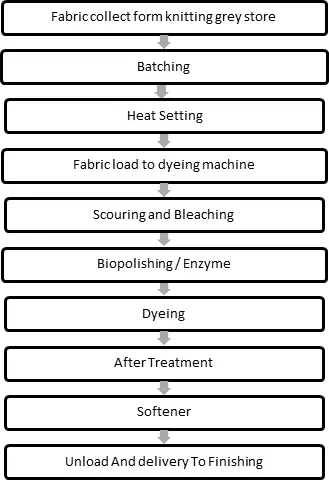

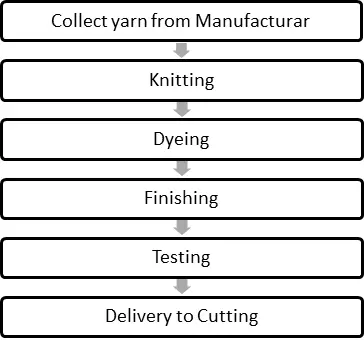

Flow Chart of Cotton Dyeing Process. Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process. A yarn is a continuous and uniform mass of fibres bounded together by the insertion of twistYarns are raw material of the fabric. Finishing accentuate or inhibiti some characteristic of fabric. Here fabric will be produced and send to the garments factory for garment production.

Source: pinterest.com

Source: pinterest.com

On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. At first spinning process is begun with converting highly compressed cotton in bales into the form of a thoroughly loosened opened and cleaned state. Parameter of finishing process in knit dyeing 1. At this point in cotton processing all of the fibers impurities and coloring bodies have been removed and the cotton fibers are pure cellulose. Here fabric will be produced and send to the garments factory for garment production.

Source: researchgate.net

Source: researchgate.net

The spinning process where raw cotton is turned into thread and the weaving process where the thread is woven into fabric. Make A Flow Chart To Show The Process Innvoled In Making Fabrics From Cotton Fibers Science Fibre Fabric 6921350 Meritnation. Weaving is done by the interlacement of these two types of yarn. But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. The main aim of wet processing is take a gray.

Source: pinterest.com

Source: pinterest.com

Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process. Put the fabric samples in the desizing liquor and carry out desizing according to the time and temperature specified. Calculation of Draft Constant. The printing flow chart depends on the fiber types. Dyeing of Aloe gel treated cotton.

Source: researchgate.net

Source: researchgate.net

From Raw Cotton to Cotton Fabrics The fabric usually used in the clothes we wear is produced through two processes. Here we will explain each process in detail using some illustrations. Yarn that has been produced in spinning mill will be sent to the Knitting or Weaving factory. Above weaving flow chart is mostly used for cotton and jute fabric. Flow chart of textile Processing Textile Fibers.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties. Normally the thickness of a yarn is expressed in terms of countCount may be defined as the number which expresses the fineness or coarseness of a yarn. Flow Chart of Cotton Dyeing Process. Roller8 air roller airing zone fabrics are dried by air and chemical is added with fabrics. De-sizing removes the sizing chemicals from the warp yarns in the woven fabric.

Source: researchgate.net

Source: researchgate.net

Fabric consider as a major raw material in the garments manufacturing process. On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. In acid medium the fabric is treated with a solution containing 30-40 mll H2O2 35 2-4 g1 organic stabilizer 025 g1 wetting agent and 025 g1 detergent at pH 55-6 acetic acid for 40-60 min at 80C or 2-25 h at 65C. This process is known. Flow chart of Scouring Process.

Source: researchgate.net

Source: researchgate.net

21 Process Water Quality The purity of the processing water has a direct effect on the performance of the preparation processes which clean the fibers the efficiency of the dyeing process and the end product color properties. Finishing is a general term which usually refers to treatment on textile fabrics after dyeing or printing. This process is known. Carry out after treatment rinse with hot water 70-95C and give a cold wash B. After carding the process is continued by drawing which includes attenuating in spinning mills.

Source: researchgate.net

Source: researchgate.net

Here fabric will be produced and send to the garments factory for garment production. Fabric inlet section. Scouring removes fatty waxes and greases from natural fibres cotton seed and husk. De-sizing removes the sizing chemicals from the warp yarns in the woven fabric. Here we will explain each process in detail using some illustrations.

Source: practicaltextile.com

Source: practicaltextile.com

It increase life and durability of the fabric. Flow chart of textile Processing Textile Fibers. A yarn is a continuous and uniform mass of fibres bounded together by the insertion of twistYarns are raw material of the fabric. 47 rows Wet processing flow chart for cotton. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same.

Source: pinterest.com

Source: pinterest.com

Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same. But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. Only the cotton picking process seems clearly destined for elimination in the near future. Yarn that has been produced in spinning mill will be sent to the Knitting or Weaving factory. The printing flow chart depends on the fiber types.

Source: textileinfomedia.com

Source: textileinfomedia.com

But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. Roller8 air roller airing zone fabrics are dried by air and chemical is added with fabrics. Cotton printing is the most used process. Finishing is a general term which usually refers to treatment on textile fabrics after dyeing or printing. Yarns are produced with different diameters and different weights per unit length.

Source: toppr.com

Source: toppr.com

Natural fiber such as- cotton wool and silk contains various types of impurities for this reason it is required to remove the impurities before dyeing and printing process. The main aim of wet processing is take a gray. Process Flow Of Printing Process For 100 Cotton Fabric. Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. Fiber means any substance that have high length to width ratio.

Source: onlineclothingstudy.com

Source: onlineclothingstudy.com

Spinning is a procedure of producingconverting fiber materials in yarns. Spinning is the initial process for fabric or ready made garments production. Oven-dry condition and weigh the sample C. Flow Chart of Cotton Dyeing Process. Although these techniques vary depending on the machine which is used for producing fabric but basic concept is same.

Source: brainly.in

Source: brainly.in

In this process the fibers in the bale form will be loosened opened and cleaned. In a spinning mill those steps of the processing carried out in the blow room. Finishing is a general term which usually refers to treatment on textile fabrics after dyeing or printing. Flow Chart Of Thermafleece Secondary Processing At John Cotton Scientific Diagram. In this process the fibers in the bale form will be loosened opened and cleaned.

Source: researchgate.net

Source: researchgate.net

The spinning process where raw cotton is turned into thread and the weaving process where the thread is woven into fabric. The silver produced. Spinning is a procedure of producingconverting fiber materials in yarns. In acid medium the fabric is treated with a solution containing 30-40 mll H2O2 35 2-4 g1 organic stabilizer 025 g1 wetting agent and 025 g1 detergent at pH 55-6 acetic acid for 40-60 min at 80C or 2-25 h at 65C. Were and still are part of the fabric of the lives of mankind.

Source: snapsolve.com

Source: snapsolve.com

Parameter of finishing process in knit dyeing 1. 47 rows Wet processing flow chart for cotton. Process flow chart of weaving technology is given below. Flow chart of Scouring Process. It is used to twist the drafted strand.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title process flow chart of cotton fabric zone by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.