Your Who process flow chart of cotton fabric in bangladesh images are ready. Who process flow chart of cotton fabric in bangladesh are a topic that is being searched for and liked by netizens today. You can Find and Download the Who process flow chart of cotton fabric in bangladesh files here. Download all free vectors.

If you’re searching for who process flow chart of cotton fabric in bangladesh images information related to the who process flow chart of cotton fabric in bangladesh keyword, you have come to the right site. Our site always gives you suggestions for seeing the maximum quality video and image content, please kindly surf and locate more informative video articles and graphics that fit your interests.

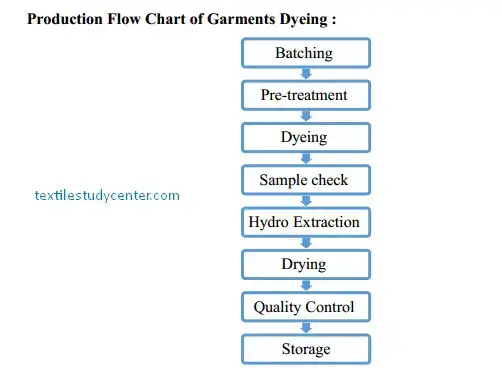

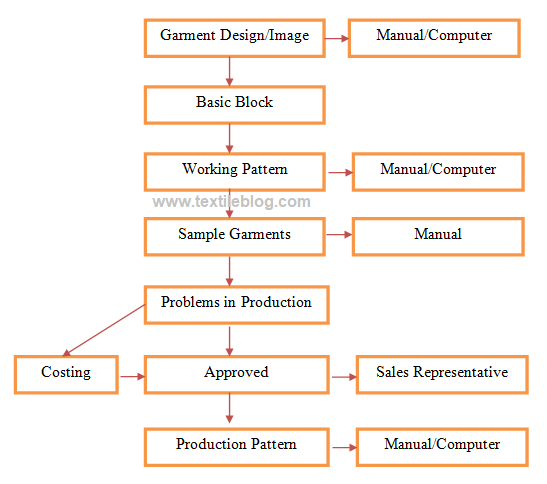

Who Process Flow Chart Of Cotton Fabric In Bangladesh. Process Flow Chart for 100 Cotton Yarn DarkMediumLight Shade. A process flow chart helps to understand how raw materials are moved from one process to another process until raw materials are transformed into the desired product garments. It can apply to most fabric materials in light or dark colours. Main purpose of cotton scouring is to eliminate natural and artificial impurities from the fabric making it cleaner and more absorbent.

Process Flow Diagram Of Textile Dyeing Industry Color Download Scientific Diagram From researchgate.net

Process Flow Diagram Of Textile Dyeing Industry Color Download Scientific Diagram From researchgate.net

The description of all stages of Textile manufacturing process are provided below. Combed cotton spinning process is another important spinning process of cotton. It is a natural and most popular fiber. Combing is done for adding extra features to the fibers. The fabric is loaded in a machine fills with required water. Anyhow following task is done one by one in different stages of the machine part.

Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes.

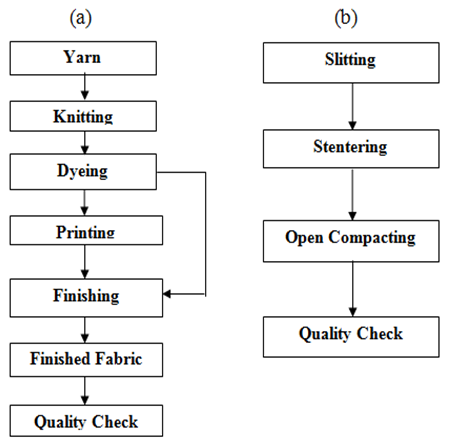

Make A Flow Chart To Show The Process Innvoled In Making Fabrics From Cotton Fibers Science Fibre Fabric 6921350 Meritnation. December 12 2016 by textile-flowchart. Higher count yarn is produced by this process. The denim fabrics are woven with a coarse count high thread density and 3 1 twill weave. Weaving is done by the interlacement of these two types of yarn. Flow Chart of Cotton Dyeing Process.

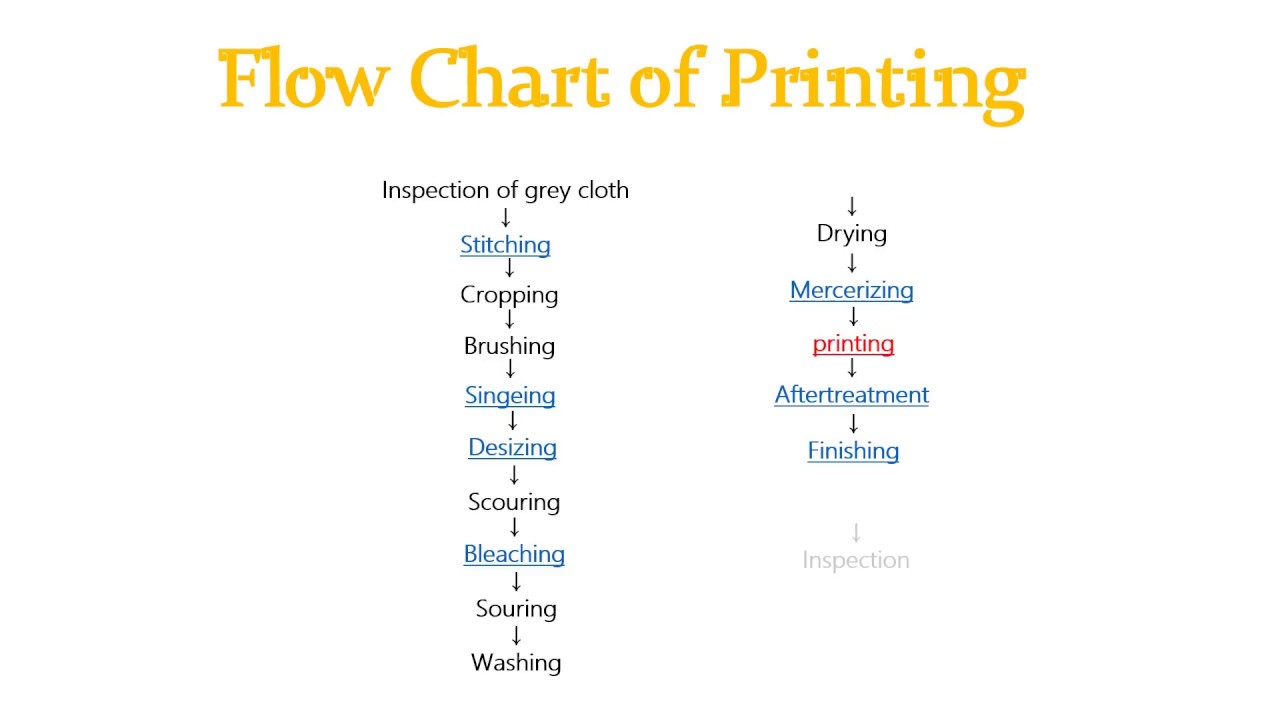

Cotton is a soft fluffy staple fiber. Check the fabric if enzyme action is proper. It can apply to most fabric materials in light or dark colours. In this dyeing process. Process Flow Of Printing Process For 100 Cotton Fabric.

Source: textilecreativities.blogspot.com

Source: textilecreativities.blogspot.com

510 while the concentration in mercerization may be up to 2225. Definition of Cotton Scouring. Winding process can be defined as the transfer of spinning yarn from one package to another large package cone spool pirn etc. Denim is the name of the fabric that is used to make jeans. The first steps is washing then mercerization is done in same machine.

Source: researchgate.net

Source: researchgate.net

Flow Chart of Cotton Bleaching Process. December 12 2016 by textile-flowchart. After winding yarn packages are used for making woven or knitted fabrics. Check the fabric if enzyme action is proper. The most important wet process used on textile products before dyeing or printing is scouring.

Source: msrblog.com

Source: msrblog.com

Flow Chart of Cotton Dyeing Process. In this dyeing process. Sample is the prototype or model of the garment upon what the buyer can decide on how and whether to confirm the order or not. Process Flow Of Printing Process For 100 Cotton Fabric. It can apply to most fabric materials in light or dark colours.

Source: msrblog.com

Source: msrblog.com

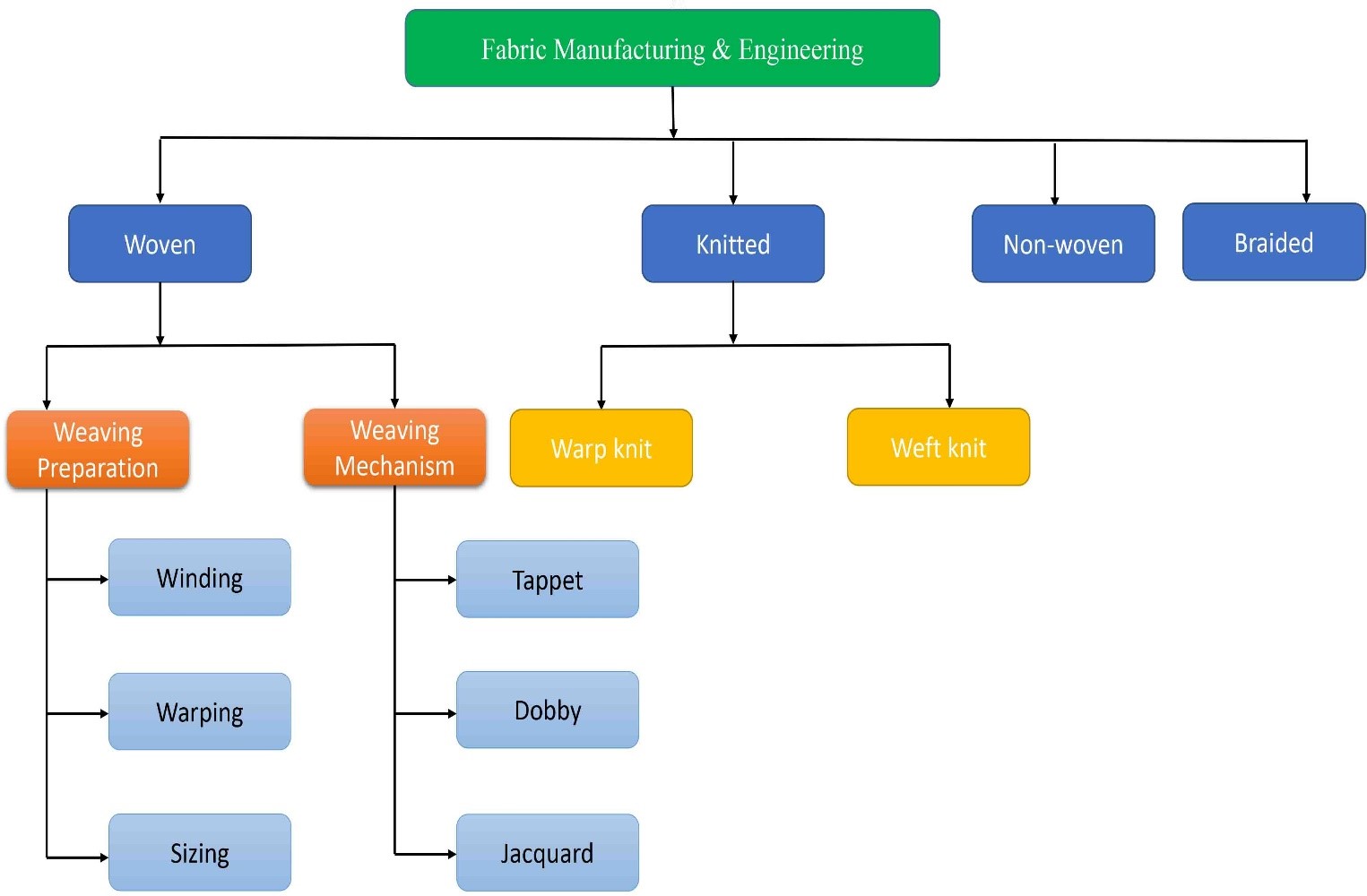

Most fabrics are knitted or woven but some are produced by non-woven processes such as braiding felting twisting etc. Weaving is done by the interlacement of these two types of yarn. Process flow chart of weaving technology is given below. Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. 510 while the concentration in mercerization may be up to 2225.

Source: researchgate.net

Source: researchgate.net

Combing is done after carding. Winding are the last steps. Combed cotton spinning process is another important spinning process of cotton. Flow chart of Cotton Spinning process-. May 18 2017 No comments.

Source: prezi.com

Source: prezi.com

Cotton is dyed with a range of dye types including vat dyes and modern synthetic reactive and direct dyes. PolyesterCotton Blended Fabric Dyeing. Sample is the prototype or model of the garment upon what the buyer can decide on how and whether to confirm the order or not. April 24 2012 Spinning Fabric Manufacturing technology. Yarn spinning is a process of making or converting fiber materials into yarnsIt is the primary Process of Textile Product.

Source: article.sapub.org

Source: article.sapub.org

A special rubber formulation has to be made in order to apply this print to elastic material Flow chart of rubber printing process on cotton fabric 7. The description of all stages of Textile manufacturing process are provided below. Now auxiliary chemicals acid are added. A process of coloring fibers yarns or fabrics with either natural or synthetic dyes. It is a durable cotton twill textile.

Source: textilestudycenter.com

Source: textilestudycenter.com

After winding yarn packages are used for making woven or knitted fabrics. For this reason this dyeing process is called the double part dyeing process. Combed cotton spinning process is another important spinning process of cotton. This process is known. May 18 2017 No comments.

Source: textilestudy365.blogspot.com

Source: textilestudy365.blogspot.com

The printing flow chart depends on the fiber types. A process of coloring fibers yarns or fabrics with either natural or synthetic dyes. Process Flow Chart of Denim Manufacturing. The enzyme is added run for 30 minutes. Process flow chart for cotton mercerizing of denim is given below.

Source: textileblog.com

Source: textileblog.com

Weaving is done by the interlacement of these two types of yarn. For this reason this dyeing process is called the double part dyeing process. But textile fibre means any substance which have high length to width ratio with suitable charateristics for being processed into fabric. Now I will give typical flow chart of cotton yarn dyeing. Cotton printing is the most used process.

Source: msrblog.com

Source: msrblog.com

Organogram of Denim Mill in Bangladesh. April 30 2015 by textile-flowchart. Cotton printing is the most used process. Anyhow following task is done one by one in different stages of the machine part. Denim is the name of the fabric that is used to make jeans.

Source: pinterest.com

Source: pinterest.com

Process Flow Chart for 100 Cotton Yarn DarkMediumLight Shade. The first steps is washing then mercerization is done in same machine. If the cloth is to be finished white or is to be given surface ornamentation all-natural color must be removed by bleaching. In the case of polyestercotton blended fabric double dyeing is done. The printing flow chart depends on the fiber types.

Source: textileinfomedia.com

Source: textileinfomedia.com

If not then increase the time. Sample is the prototype or model of the garment upon what the buyer can decide on how and whether to confirm the order or not. In the case of polyestercotton blended fabric double dyeing is done. Check the fabric if enzyme action is proper. Fabric is a plain sheet of cloth which is made from natural or man-made fibers by weaving or knitting process.

Source: textileflowchart.com

Source: textileflowchart.com

A process flow chart helps to understand how raw materials are moved from one process to another process until raw materials are transformed into the desired product garments. It is a durable cotton twill textile. Process Flow Chart of Denim Manufacturing. Main purpose of cotton scouring is to eliminate natural and artificial impurities from the fabric making it cleaner and more absorbent. Flow Chart of Cotton Dyeing Process.

Source: pinterest.com

Source: pinterest.com

Flow chart of Cotton Spinning process-. Check the pH 34-48 of liquor. The fabrics are usually turned to keep away from the any unaccepted incident or damage on face side and remove edge marks which are created due to formation of fabric roll. Steps of fabric processing in mercerization machine. Cotton Spinning process flow chart.

Source: youtube.com

Source: youtube.com

April 24 2012 Spinning Fabric Manufacturing technology. Fabric consider as a major raw material in the garments manufacturing process. A special rubber formulation has to be made in order to apply this print to elastic material Flow chart of rubber printing process on cotton fabric 7. A process flow chart helps to understand how raw materials are moved from one process to another process until raw materials are transformed into the desired product garments. This is also necessary if discoloration or stains have occurred during the previous manufacturing process.

Source: researchgate.net

Source: researchgate.net

On an initial stage it goes through the blowroom where the size of cotton becomes smaller by the help of machinery followed by carding. A special rubber formulation has to be made in order to apply this print to elastic material Flow chart of rubber printing process on cotton fabric 7. The enzyme is added run for 30 minutes. For this reason this dyeing process is called the double part dyeing process. The first steps is washing then mercerization is done in same machine.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title who process flow chart of cotton fabric in bangladesh by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.