Your Why dyeing process of cotton fabric pdf images are available in this site. Why dyeing process of cotton fabric pdf are a topic that is being searched for and liked by netizens now. You can Get the Why dyeing process of cotton fabric pdf files here. Download all royalty-free images.

If you’re looking for why dyeing process of cotton fabric pdf images information related to the why dyeing process of cotton fabric pdf interest, you have come to the ideal blog. Our website always provides you with suggestions for seeking the maximum quality video and image content, please kindly hunt and find more informative video content and images that fit your interests.

Why Dyeing Process Of Cotton Fabric Pdf. Microencapsulation is a process by which individual particles of an active agent can be stored within a shell surrounded or coated with a continuous film of polymeric material to produce particles in the micrometre to millimetre range. This twill weaving produces a diagonal ribbing that distinguishes it from cotton duckWhile a denim predecessor known as dungaree has been produced in India for hundreds of years denim as it is recognized today was first produced in Nîmes France. These Dyeing of Fabrics are generally used for dyeing cotton silk nylon polyester etc. Name the sources of obtaining fibres.

Pdf Dyeing Of Cotton Fabric With Natural Dyes Improved By Mordants And Plasma Treatment From researchgate.net

Pdf Dyeing Of Cotton Fabric With Natural Dyes Improved By Mordants And Plasma Treatment From researchgate.net

After dyeing allow the pieces to dry and set. Orange - 1 5. The fabric is now bleached and dyed at a finishing plant. Denim is a sturdy cotton warp-faced textile in which the weft passes under two or more warp threads. Microencapsulation is a process by which individual particles of an active agent can be stored within a shell surrounded or coated with a continuous film of polymeric material to produce particles in the micrometre to millimetre range. On the other hand fabric is the accumulation of many fibre threads which are hard to break and needs an enormous amount of energy to break the fabric.

It takes more than 5000 gallons of water to manufacture just a T-shirt and a pair of jeans.

Perfect for many doll patterns recommending 100 cotton weave. Non-cellouse materials oil fat and wax. Fabric made in the loom is grey in colour. Microencapsulation is a process by which individual particles of an active agent can be stored within a shell surrounded or coated with a continuous film of polymeric material to produce particles in the micrometre to millimetre range. These Dyeing of Fabrics are generally used for dyeing cotton silk nylon polyester etc. Section c This section was widely known.

Source: pinterest.com

Source: pinterest.com

It is easy to break a fibre thread as it is fragile and easy to break as well. After all the pieces have been dyed and allowed to oxidize go ahead and repeat the dying process. This process is called shearing. It takes more than 5000 gallons of water to manufacture just a T-shirt and a pair of jeans. As there is only surface absorption the colour is not very fast.

Source: pinterest.com

Source: pinterest.com

Microencapsulation is a process by which individual particles of an active agent can be stored within a shell surrounded or coated with a continuous film of polymeric material to produce particles in the micrometre to millimetre range. The sources of obtaining fibres are plants and animals. Also a number of techniques are used for producing fabrics such as weaving knitting and felting. Fibre to Fabric Class 7 Extra Questions Science Chapter 3 Fibre to Fabric Class 7 Science Extra Questions Very Short Answer Type Question 1. Scouring is the process of industrial cleaning of fabrics with the help of.

Source: researchgate.net

Source: researchgate.net

- Length - 1 yard - Width - 4445. As there is only surface absorption the colour is not very fast. Bleaching is used to reduce natural color of the raw materials. 20000 liters is the amount of water needed to produce one kilogram of cotton. Section b ii Candidates were able to answer this section correctly for the most part.

Source: researchgate.net

Source: researchgate.net

The fabric is now bleached and dyed at a finishing plant. Name the sources of obtaining fibres. On the other hand fabric is the accumulation of many fibre threads which are hard to break and needs an enormous amount of energy to break the fabric. The manipulations of the fabric before the application of dye are. This twill weaving produces a diagonal ribbing that distinguishes it from cotton duckWhile a denim predecessor known as dungaree has been produced in India for hundreds of years denim as it is recognized today was first produced in Nîmes France.

Source: pinterest.com

Source: pinterest.com

Machines similar to those used by barbers are used to shave off hair. Comditel deals with dyeing patterning and finishing undyed fabric. The most common way to print a fabric in full width is to use pigment prints where the pigments stick to a surface using polymeric resin or a binder. Most candidates were able to explain why the steps involved in the dyeing process were necessary. Fabric is made of a thin hair-like strand called fibres.

Source: researchgate.net

Source: researchgate.net

After all the pieces have been dyed and allowed to oxidize go ahead and repeat the dying process. Orange - 1 5. Equivalent to a single t-shirt and pair of jeans. Wool yielding animals are sheep yak llama. The finishing process and fabric pilling share a link.

Source: pinterest.com

Source: pinterest.com

- Length - 1 yard - Width - 4445. Name the sources of obtaining fibres. Bleaching is used to reduce natural color of the raw materials. Cotton Incorporated research labs improve cotton by focusing on nonwovens innovations product development trend analysis and modern dyeing and finishing techniques. - Length - 1 yard - Width - 4445.

Source: co.pinterest.com

Source: co.pinterest.com

Fibre to Fabric Class 7 Extra Questions Science Chapter 3 Fibre to Fabric Class 7 Science Extra Questions Very Short Answer Type Question 1. After all the pieces have been dyed and allowed to oxidize go ahead and repeat the dying process. Anti-pilling and pilling properties of the fabric will create large changes related to the conditions of dye auxiliaries and the finishing. Bleaching is used to reduce natural color of the raw materials. After cutting and dyeing the items are stitched with help of many local cooperatives.

Source: es.pinterest.com

Source: es.pinterest.com

The type of fabrics varies by the fibres the fabric formation techniques machinery used for producing them and finishing techniques. However some candidates were unable to express themselves using. 20000 liters is the amount of water needed to produce one kilogram of cotton. Wool yielding animals are sheep yak llama. We have 3 beautiful doll skin colors - Shell Pink Tea-Dyed and Praline.

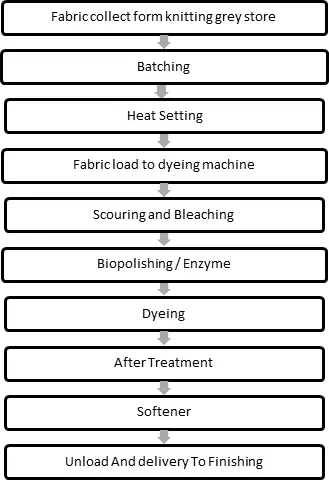

Source: practicaltextile.com

Source: practicaltextile.com

The reaction involves the coupling between napthal absorbed on the surface of the fabric with the diazonium salt. We have 3 beautiful doll skin colors - Shell Pink Tea-Dyed and Praline. Dyeing also consumes 5 trillion liters of water each year2 which is nearly enough to supply all humanity with drinking water. Dyeing performance of fabric depends on the process bleaching. Fabric is made of a thin hair-like strand called fibres.

Source: pinterest.com

Source: pinterest.com

It is planted early in the spring. Wool yielding animals are sheep yak llama. Usually hair are removed during the hot weather. This twill weaving produces a diagonal ribbing that distinguishes it from cotton duckWhile a denim predecessor known as dungaree has been produced in India for hundreds of years denim as it is recognized today was first produced in Nîmes France. However some candidates were unable to express themselves using.

Source: pinterest.com

Source: pinterest.com

According to Green America textile dyeing is the second largest polluter of water globally. Anti-pilling and pilling properties of the fabric will create large changes related to the conditions of dye auxiliaries and the finishing. Scouring is the process of washing fabric with soap solution. Scouring removed natural impurities such as. It is easy to break a fibre thread as it is fragile and easy to break as well.

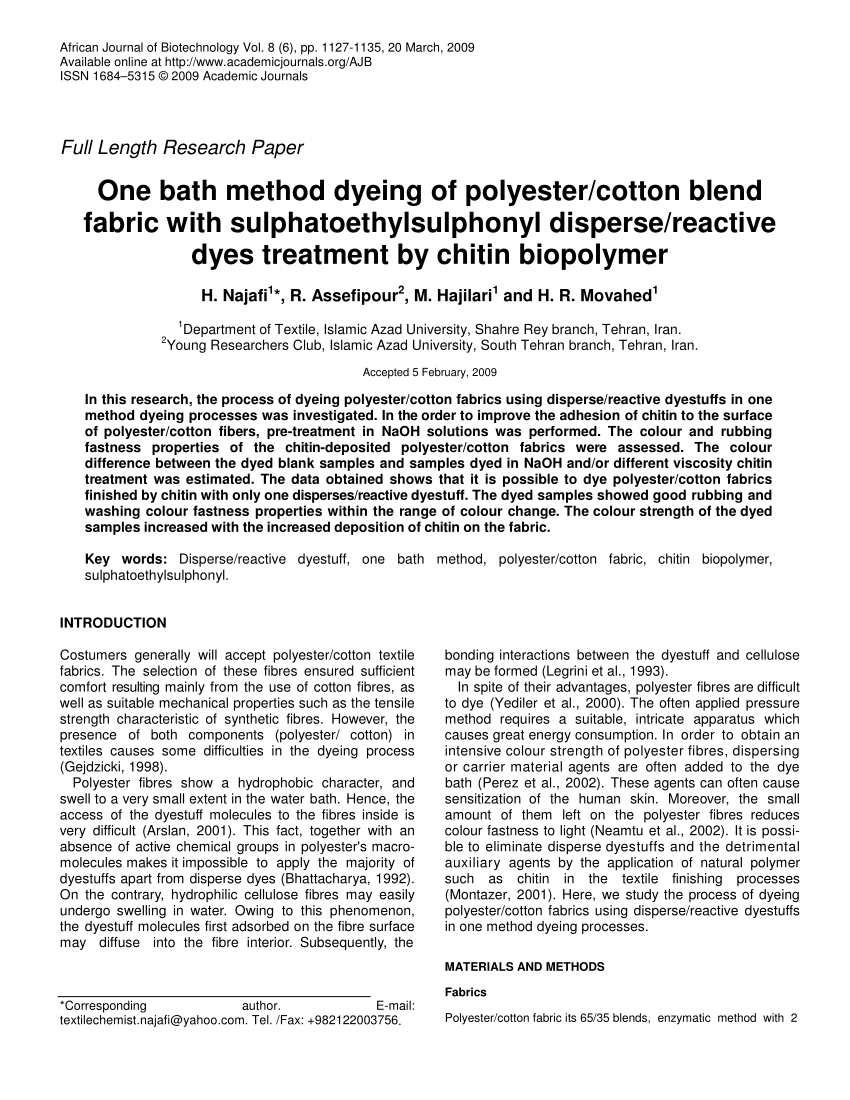

Source: researchgate.net

Source: researchgate.net

Mercerization for instance is the process of treating cotton yarns or fabrics with sodium hydroxide for increasing absorbency lustre softness and strength. This twill weaving produces a diagonal ribbing that distinguishes it from cotton duckWhile a denim predecessor known as dungaree has been produced in India for hundreds of years denim as it is recognized today was first produced in Nîmes France. The manipulations of the fabric before the application of dye are. Fabric made in the loom is grey in colour. What is its course of growth.

Source: pinterest.com

Source: pinterest.com

- Length - 1 yard - Width - 4445. By reducing the water chemicals dye and energy required to color cotton textiles we can help brands meet sustainability targets while also addressing climate change water pollution and water scarcity. The fleece of the sheep along with a thin layer of skin is removed from its body Fig. These Dyeing of Fabrics are generally used for dyeing cotton silk nylon polyester etc. The manipulations of the fabric before the application of dye are.

Source: researchgate.net

Source: researchgate.net

Anti-pilling and pilling properties of the fabric will create large changes related to the conditions of dye auxiliaries and the finishing. Why they are also called as ingrain Dyeing of Fabrics. On the other hand fabric is the accumulation of many fibre threads which are hard to break and needs an enormous amount of energy to break the fabric. The process increased the fabric absorbency and luster of the fabric dying and printing. This process is called shearing.

Source: fi.pinterest.com

Source: fi.pinterest.com

The manipulations of the fabric before the application of dye are. Fabric Technology Learn how new performance technology innovations enhance cottons natural properties to perform as good as or better than synthetics. The process increased the fabric absorbency and luster of the fabric dying and printing. Fabric is woven the presence of these additives hinders further finishing processes such as bleaching dyeing printing etc. Orange - 1 5.

Source: pinterest.com

Source: pinterest.com

According to Green America textile dyeing is the second largest polluter of water globally. Fibre to Fabric Class 7 Extra Questions Science Chapter 3 Fibre to Fabric Class 7 Science Extra Questions Very Short Answer Type Question 1. Fabric is woven the presence of these additives hinders further finishing processes such as bleaching dyeing printing etc. After dyeing allow the pieces to dry and set. Tie dyeing is a favorite fabric craft for kids and adults of all ages.

Source: researchgate.net

Source: researchgate.net

- Length - 1 yard - Width - 4445. Microencapsulation is a process by which individual particles of an active agent can be stored within a shell surrounded or coated with a continuous film of polymeric material to produce particles in the micrometre to millimetre range. Impact of the method of dyeing and finishing. This process is called shearing. Fabrics can also be made differently based on the end-usage.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title why dyeing process of cotton fabric pdf by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.